Botou Golden Integrity Roll Forming Machine Co., Ltd |

|

Verified Suppliers

|

|

Automatic Color Metal Corrugated Wave Roof And Wall Panel Cold Roll Forming Machine

1. Description Of Corrugated Sheet Roll Forming Machine

The metal corrugated roof and wall panel is widely used for commercial and residential metal buildings, associated with residential and commercial. Corrugated Sheet Roll Forming Machine could be customized designed for its production.

It’s also named metal roofing galvanized aluminum corrugated steel sheet making machine colored steel wall roof panel cold roll forming machine, metal roofing galvanized aluminum corrugated steel sheet making machine colored steel wall roof panel cold roll forming machine,

Because the thickness of the working material is different, the yield strength is different, and the profile profile is different, these factors affect the configuration of the machine is different, so if you want to customize a metal corrugated roof roll forming machine, please send me your profile drawing, the thickness of your material, yield strength, etc., so that our engineers can help you customize the right machine according to your requirements.

If you have requirements for production speed, power, voltage and brand, please explain in advance.

2. Technical Details Of Corrugated Sheet Roll Forming Machine

| Machine Specifications | |

| Weight | About 4.6tons |

| Size | About 6.5m x 1.2mx1.3m(length x width x height) |

| Color | Main color: bule or as your need |

| Warning color: yellow | |

| Suitable Raw Material | |

| Material | GI PPGI GL PPGL |

| Thickness | 0.3-0.8mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 22 |

| Diameter of forming rollers shafts | 70mm |

| Roll Forming Speed | 15m/min |

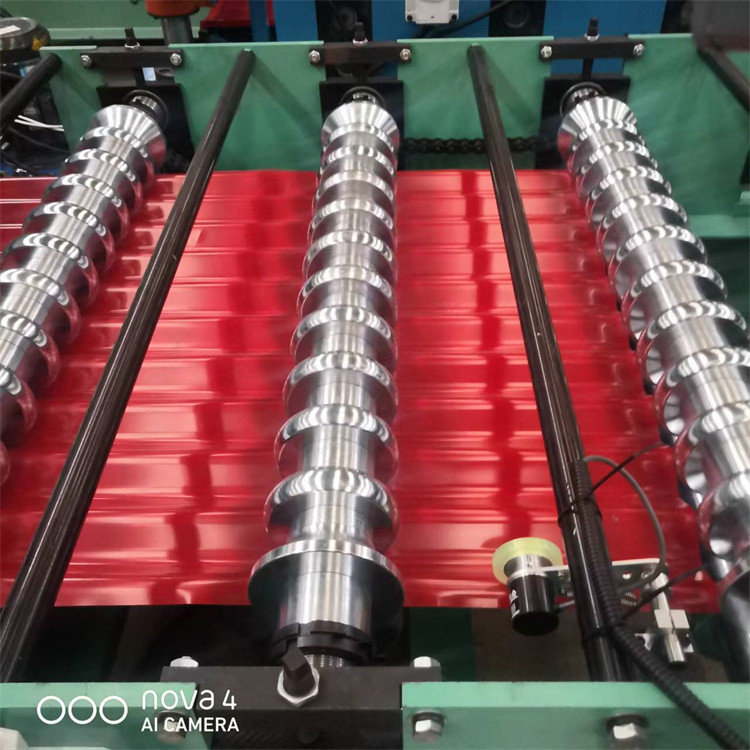

| Forming rollers material | 45# steel, coated with chromed treatment |

| Cutter material | Cr12MOV, with quenched treatment |

| Controlling system | PLC |

| Electric Power requirement | Main motor power: 4kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

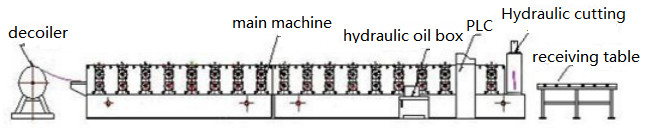

3. Main Components Of Corrugated Sheet Roll Forming Machine

| Manual Decoiler | 1 Set |

| Feeding Table | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows Of Corrugated Sheet Roll Forming Machine

Decoiler → feeding table (sheet metal is put by guiding platform) → main forming machine → Hydraulic cutting system → Receiving table

5. Advantages Of Our Corrugated Sheet Roll Forming Machine

· More than 10 engineers and More than 10 designers with more than 10 years experience

· We have completed production system. And have high precious CNC grinders and milling machines,to make the rollers and shafts of the machine.

· Our machine's warranty period is 12 months and and we supply the technical support for the whole life of the equipment.

· We have professional engineer to check the quality of all parts. we do every step carefully to make sure the quality.

6. Application Of The Corrugated Sheet Roll Forming Machine

This machine is widely used in the production of the metal roof sheets and wall panel. our machines are exported to many countries: Rwanda, Thailand, Philippines, Dubai, USA, South Africa, Peru, Russia, Saudi Arabia, Malaysia, Indonesia, etc.

7. Product photos Our Corrugated Sheet Roll Forming Machine

8. FAQ

Q. What your company advantages?

A: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before delivery. Of course your payment terms are acceptable. After we get down payment, we will arrange production. About 30-45 days for delivery.

Q: How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

Q. What will you do if the machine is broken?

A: We provide 12 months free warranty and free technical support for the whole life of any machine. If the broken parts can't repair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.