Jiangsu Lebron Machinery Technology Co., Ltd. |

|

Full Automatic Metal Steel Cable Tray Roll Forming Machine manufacturer

1. Description of Cable Tray Industry Forming Machines

The perforated Cable Tray Roll Forming Machine is a duplex and high performance production line for manufacture C section profile with slotted holes for supporting electric wiring in commercial and industrial construction. The cable tray which was produced by Cable Tray Roll Forming Machine usually made from middle gauge steel thickness from 0.8~2.0mm.

The perforated Cable Tray Roll Forming Machine successfully integrated hydraulic punching device or high speed press machine for radiation holes on cable tray. Also, the telescope shaft is available to rapid size changeover without toll change. Pre-cut or post cut can both equipped for cut off finished product.

A whole Cable Tray Roll Forming Machine including the Decoiler, Guide device, Straighten rollers, Main Roll Forming Machine, Hydraulic system, The PLC control system and Ran-out tables. Our roll forming machine equipped with the computer control system. You just need to program in the computer the piece and length you need, then the roll forming machine produces it automatically. The machine is easy to operate, and operate stably.

2. Technical Parameters of the Cable Tray Roll Forming Machine

| No. | Item | Description |

| 1 | Suitable Material | Galvanized Steel Coil |

| 2 | Thickness | 0.8~2.0mm |

3 | Roller Material | GCr15 Steel, Quenching and Tempering, coated with Chrome |

| 4 | Shaft Material | 45# Steel, Quenched, coated with hard chrome |

| 5 | Shaft Diameter | Dia 90mm |

| 6 | Roller Stations | 20 Stations |

| 7 | Forming Speed | 12m/min |

| 8 | Hydraulic Cutting | Cr12MoV Steel, Quenched 58~61HRC |

| 9 | Main Power | 22 Kw |

| 10 | Hydraulic Station Power | 11 Kw |

3. Main Components of Cable Tray Roll Forming Machine

| No. | Item | Quantity |

| 1 | Uncoiler | 1 Set |

| 2 | Servo Feeder | 1 Set |

| 3 | Hydraulic Punching Device | 1 Set |

| 4 | Cable Tray Roll Former | 1 Set |

| 5 | Hydraulic Cutting | 1 Set |

| 6 | Hydraulic Station | 1 Set |

| 7 | Ran-out Table | 2 Sets |

| 8 | PLC Control System Cabinet | 1 Set |

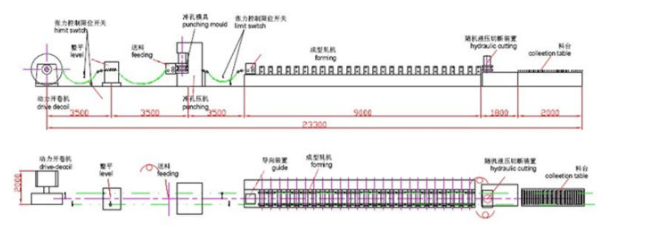

4. Layout of Cable Tray Roll Forming Machine

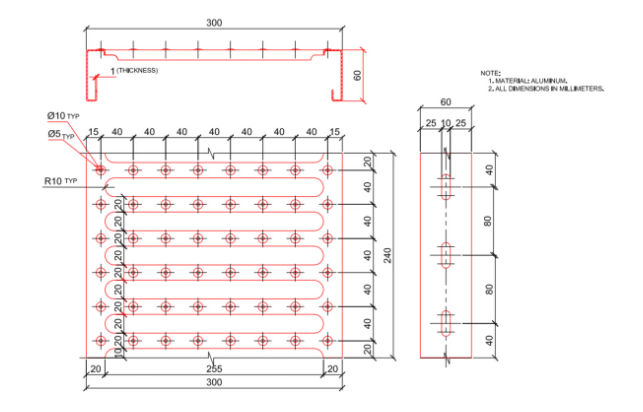

5. Sketch of Cable Tray

5. Our Advantage

6. Our Service

Install and Training:

If buyers come to our factory to inspect, the training to install and operate is provided face to face.

If not, manual and video is provided to show how to install and operate.

After-sale Service:

We provide 12-hour online service for our customers. Phone: +86 15821208506

a .The seller will debug the machines freely in China, and the traffic expense in China of the technique people will be paid by the seller.

When technique men go to the buyer's place to debug the machines, the buyer should pay the

expense of accommodation, and round-trip tickets for the seller’s men. and pay the technician USD60 per day.

b. If the buyer sends people to receive the training of the operation given by the seller, during the training period, the seller should pay the expense of accommodation, and traffic for the buyer's men.