FRIENDSHIP MACHINERY CO,LTD |

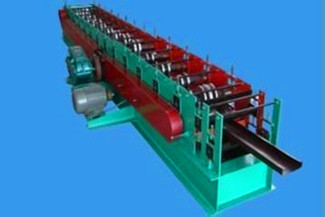

415V C Z Purlin Roll Forming Machine

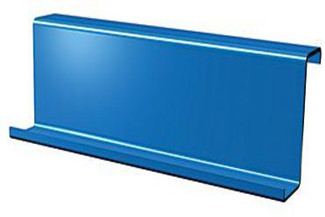

For 80-300mm C&Z Steel Purlin

Introduction Of Machine

Production Detail(quick details)

Condition: | New |

Type: | C&z purlin roll forming machine |

Coil type: | Hot-zinc coils& Hot Rolled coils |

Use: | Roof |

Production Capacity: | 10-12m/min |

Place of Origin: | Wu Xi China |

Brand Name: | Friend Ship |

Main Power: | 15KW |

Hydraulic Power: | 7.5KW |

Voltage,Frequency,Phase: | 415V,50Hz,3Phase |

Dimension(L*W*H): | 11000mm*1400mm*1400mm |

Weight: | 14000kg |

Warranty: | One year warranty maintenance free life |

After-sales Service Provided | Engineers available to service machinery overseas |

color: | As your request |

Thickness: | 1.2-3mm |

roller: | 17-18 rollers |

Roller material: | 45# forge steel |

Automation: | Automatic |

cutting blade: | Cr12 with heat treatment |

Kind of drive: | Transmission by by Chains 1.2Inch double line |

Life time: | At least 20 years |

Specifications

Welcome to view our roll forming machine we are manufacture save space excellent quality complete service.

CLICK THIS PIC ,YOU WILL SEE A VIDEO CLICK THIS PIC ,YOU WILL SEE A VIDEO

Technical parameters

No. | Item | Description |

1 | Suitable material | Strip steel |

2 | Working speed | 10-12m/min not including punching and cutting |

3 | Main motor power | 15kw with cycloidal reducer |

4 | Hydraulic station power | 7.5KW |

5 | Electrical control system | PLC control system (Panasonic) |

6 | Thickness of material | 1.2-3mm |

7 | Shaft diameter | 80mm |

8 | Roller station | 17-18stations |

9 | C&Z Purlin Width | 80-300mm |

10 | Dimension | 11000mmX1400mmX1400mm |

11 | Driving mode | Chain |

12 | Electric tension | 415V 3phase 50HZ or as the customer's requirements |

13 | Material of roller | High grade 45# forged steel plated with hard chrome plating |

14 | Material of cutting | Cr12 with heat treatment |

15 | Working time | Can be 24 hours |

16 | Workers | 1-2 only |

Components of line

NO | Name | Unit | Qty |

1 | Hydraulic/Manual decoiler | set | 1 |

2 | Main machine for roll forming | set | 1 |

3 | PLC Control system | set | 1 |

4 | Hydraulic station | set | 1 |

5 | Hydraulic cutting and punching | set | 2 |

6 | Straightening | set | 1 |

7 | Production out table | set | 2 |

Noted:All the parameters can be changed as the customer's requirement.

Features of the production line

Introduction of our company

We, Friendship Machinery Co.,Ltd, attaches great importance on technology innovation,progress has been made on scientific management as well as Co.,culture.China leading expert in designing and manufacturing equipments for welding and cutting, automation system and metal works. We use and produce high-technology utilizing the most available robotic and automatic techniques. Every work is uncompromisingly designed to improve our clients' competitiveness and productivity.

We invest more on developing roll forming machine such as Metal roof & wall panels machines,C&Z purlin machines drywall Stud-track forming machines,Metal decks machines,No-girder and Column curves forming machine,Guard rails forming machines,Downspout pipes forming machines and so on.With fast development ,very short period for construction and beautiful external appearance,as well reasonable price was occupied in the market of building industry.

EXCELLENT QUALITY AND COMPETITIVE PRICE!

CHOOSE US , CHOOSE THE BEST!

Thank you for your time!