FRIENDSHIP MACHINERY CO,LTD |

|

Product Description

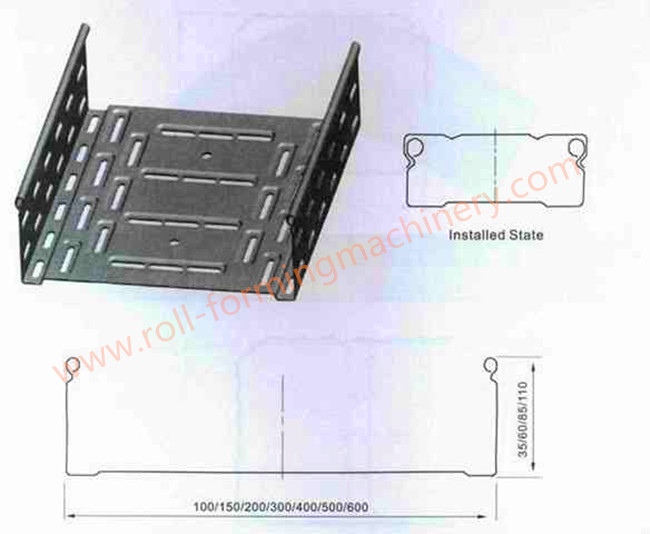

Quick Details

Item | Description |

Name | Cable Tray Roll Forming Machine |

Thickness of material | 0.8-2.0mm |

Un-coiler | 6 Tons Manual |

Forming speed | 2-4m/min |

Roller stations | 24 stations |

Main motor power | 22KW |

Control system | PLC with touch screen |

Power supply | 380V,50HZ,3Phase |

Package | Film and Steel |

After-sales Service Provided | Engineers available to service machinery overseas |

Technical parameter

Item | Description | |

Material | Material width | 200-950mm |

Material thickness | 0.8-2.0mm | |

Un-coiler | 6 tons manual | |

Forming system | Rolling speed | 2-4m/min |

Roller stations | 24 stations | |

Roller material | GCr15 quench treatment | |

Shaft DIA | 65mm | |

Main Motor power | 22Kw | |

Cutting system | Material of Cutting | Cr15 with quench treatment |

Hydraulic cutting power | 5Kw | |

Electrical control system | Electric | 380V,50HZ,3Phase |

Control system | PLC(Panasonic) | |

Main Components of machine

NO. | Name | Unit | QTY |

1 | Manual un-coiler | set | 1 |

2 | Guide/Leveling device | set | 1 |

3 | Servo feeding device | unit | 1 |

4 | Press machine | unit | 1 |

5 | Main roll forming machine | set | 1 |

6 | Hydraulic station | set | 1 |

7 | Hydraulic cutting | set | 1 |

8 | Control system( including control box) | set | 1 |

9 | Out tables | unit | 2 |

10 | Spare parts | package | 1 |

Technological process

Un-coiler—Feeding—Leveling—Punching&Cutting—Roll forming—Output table

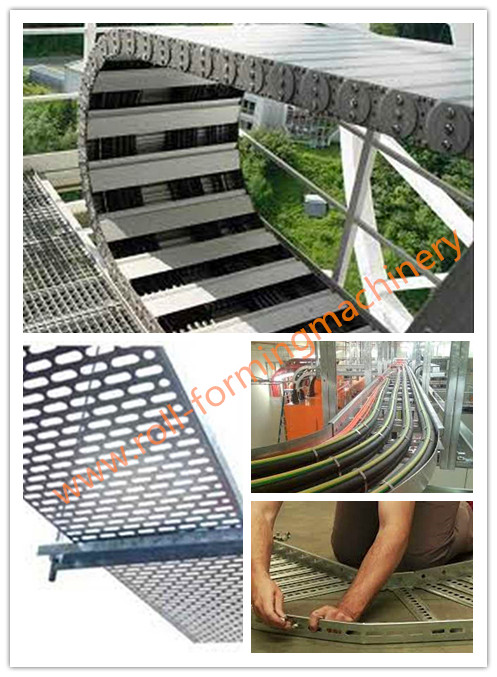

Applications of production

Pictures of machine

Introduction of company

We, Friendshachinery Co., Ltd, attaches great importance on technology innovation,progress has been made on scientific management as well as Co.,culture.Our manin products: Metal roof &wall panels machines, C&Z purlin machines drywall Stud-track forming machine,Metal decks machines,No- girder and Column curves forming machines,Guard rails forming machine,Downspout pipes forming machines and so on.

We can customize forming machine according to user's requirements.And we can provide professinal service,high quality,through design,and installation.

Warmly welcome to visit our factory no matter you are distibuters or end-users,and looking forward to cooperating with you for mutual benefits.

Contact Us

For more information, feel free to contact with us.

Skype:vivian_866

Mobile:86-15261519246

E-mail:sales02@roll-formingmachinery.com

vivianlucky866@gmail.com