Xiamen BMS Group |

|

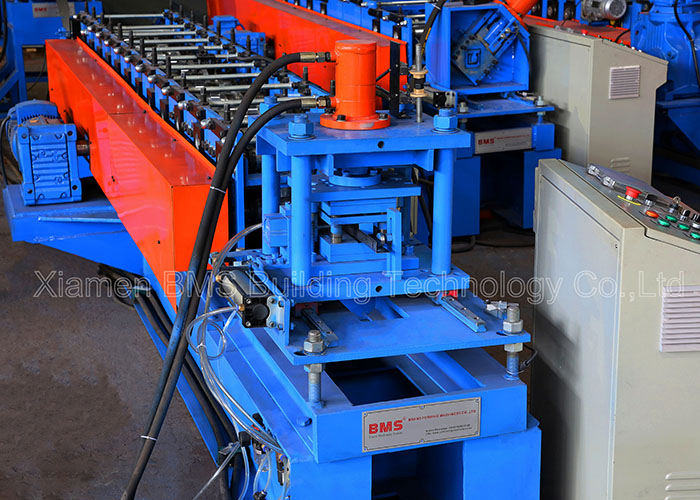

1.5-2.0 Thickness Shelf Bracket Roll Forming Machine with Servo Feeding Device

Shelf Bracket Roll Forming Machine produces rack shelves for supermarkets, warehouses, small markets, racks, cooling rooms.

Brand Forming Machinery Co., Ltd. Owns a set of mature shelf production technology, such as Shelf Bottom Beam, Shelf Support, Shelf Rack, Pallet Rack, Shelf Hanging Plate, Shelf Column, Shelf Diagonal Keel, Pallet Rack Step Beam, etc.

This machine is used to produce a shelf-mounted board production line

Working flow: Decoiler ---- Levelling---Punching-- Roll Forming ---- Cutting ---- Production support table—PLC control Cabinet

Servo Feeding Device

De-coiler--------------------------------------------1set

Leveling Device-----------------------------------1set

Hydraulic punching device---------------------1set

Hydraulic pump station--------------------------1set

Roll Forming Mill

Feeding Guide-------------------------------------1set

PLC Control cabinet -----------------------------1set

Production support table------------------------1set

1. Width of material: According to the final confirmed drawing

2. Forming steps: About 12 steps

3. The material of rollers: GCr15 steel, precision-machined,

high-frequency quenching HRC58-62, a diameter of rollers: Φ65 mm

4. The material of the main shaft: 45# high-quality steel, a

diameter of shaft: Φ65 mm

5. Chains’ material: 45# steel, high-frequency quenching

6. Cutting: Hydraulic cutting after forming; Cutting material:

Cr12Mov; quenching HRC58-62

7. Electronic control: PLC control Cabinet

8. Drive mode: Chain drive

9.Forming speed:15-18m/min

10. Welding structure: material of fixed beam and walking beam:

hot-rolled steel, the base, and rack are gantry planer processing

after welded, work platform is not allowed stress deformation; main

machine table-board’s plainness <2mm/1000mm

11. Screw nut: 8.8 Grade arken;

12.Bearing: HRB

13. Punching: Punching the holes before forming.

14. Cutting: Hydraulic.

15.Power:2.2KW+2.2KW+4.4KW+5.5KW+15KW

16. Dimension of machine: 13000mmX1200mmX1800mm

| Name | Size |

| Decoiler and Leveling | 1600*1200*1500mm |

| Punching device | 1700*1100*1800mm |

| Roll Forming Mill | 7000*1500*1700mm |

| Production support table | 3000*1400*1400mm |

| Placement size recommendations | 200000*1500*1800mm |