Xiamen BMS Group |

|

High-Speed Metal Stud And Track Roll Forming Machine 30-40 Meters Per Minute

High Speed Stud and Track Roll Forming Machine(1 machine for multi-profiles,size-changing by spacer)

1.Main features of a high-speed stud and track roll forming machine

The advantages of a high-speed stud and track machine are as follows:

1. The speed can reach 30-40 meters per minute

2. Enlarged hydraulic station to ensure high-speed working

3. Easy operation, low maintenance cost

4. Beautiful appearance.

5. One machine for multi-profiles,size-changing by the spacer

2.Detailed Images of stud and track roll forming machine

Machine Parts

1) High-speed stud and track machine arc feeding guide

Brand: BMS Original: China

Arc Feeding Guide(make feeding smooth and no wrinkling)

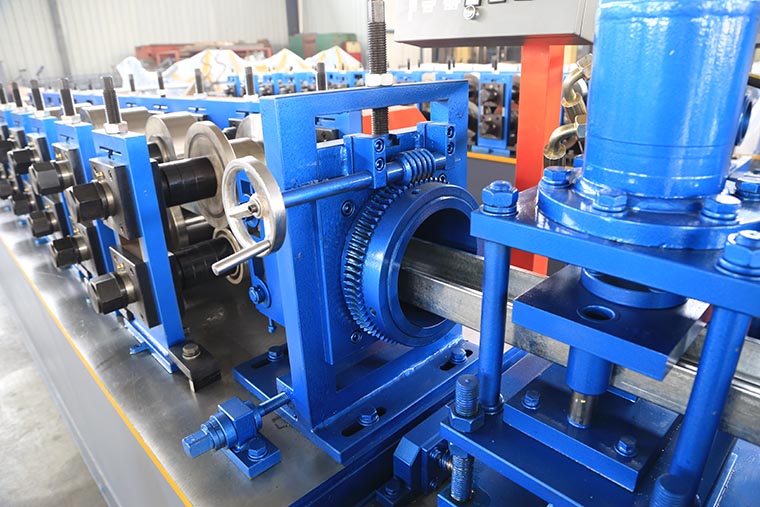

2) High-speed stud and track machine rollers

Brand: BMS Original: China

Rollers manufactured from hong life mould steel Cr12=D3 with heat treatment, CNC lathes,

Heat Treatment. (with black treatment or Hard-Chrome Coating for options).

With feeding material guide, body frame made from 400# H type steel by welding

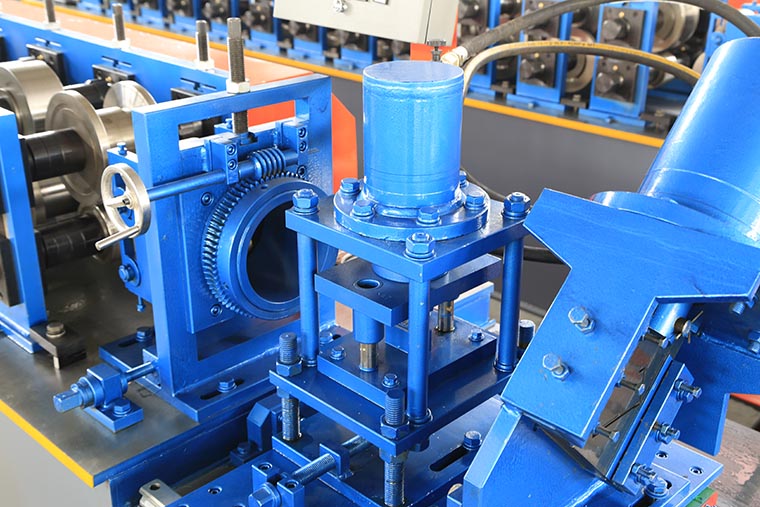

3) High-speed stud and track machine straightening and logo punching device

Brand: BMS Original: China

4) High-speed stud and track machine flying cutting

(machine for multi-profiles,size-changing by spacer)

Brand: BMS Original: China

made by high-quality long-life mould steel Cr12Mov with heat treatment

Cutter frame made from high quality 30mm steel plate by welding

hydraulic motor:5.5KW, Hydraulic pressure range: 0-16Mpa

5) High-speed stud and track machine hydraulic system

Brand: BMS Original: China

Enlarged hydraulic station to ensure high-speed working

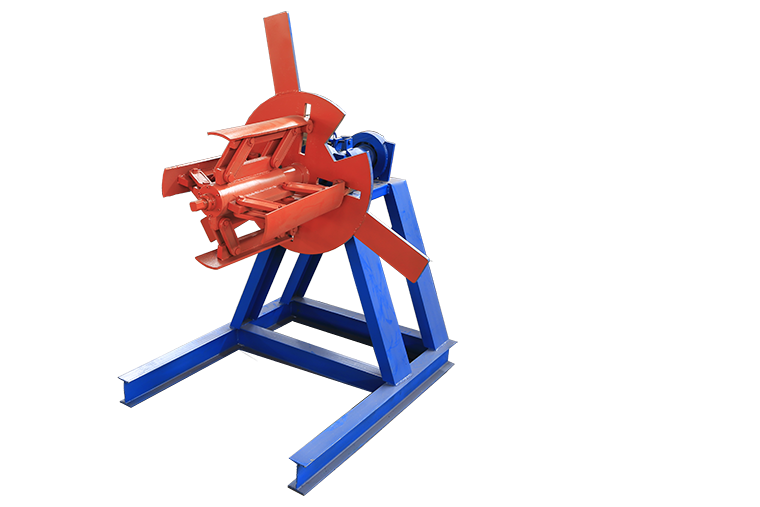

6) High-speed stud and track machine decoiler

Brand: BMS Original: China

ManualDecoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 508mm±30mm

Capacity: Max. 3Ton

With 3 tons hydraulic decoiler for option

7) High-speed stud and track exit rack

Brand: BMS Original: China

Un-powered,4meters long, one unit

Other detailes of a high-speed stud and track roll forming machine

Suitable for material with thickness 0.6-1.2 mm

Shafts manufactured from 45#, Main shaft diameter=φ75mm, precision machined

Motor driving, Gear chain transmission, 12 rollers to form.

Main servo motor=2.0KW, Frequency speed control. Forming speed of approx.30-40m/min

PLC Control System (Touch screen brand: German Schneider Electric/Taiwan WEINVIEW,

Inverter brand: Finland VOCAN/Taiwan DELTA/ALPHA, Encoder brand: Japan Koyo/OMRON)

Combined with: PLC, Inverter, TouchScreen, Encoder, etc

Cut-to-lengthtolerance≤±2 mm

Control Voltage 24V

User's manual in English