Xiamen BMS Group |

|

Similar as SAMCO Greenfield Stud & Track roll forming line

1. Main features of quickly change Stud & Track roll forming line

The advantages of Stud & Track roll forming line are as follows:

1. Quick-Change type Stud & Track roll forming machine

2. Produce 95% of the stud and track sizes used in the industry.

3. Similar as SAMCO Greenfield Stud & Track roll forming line

4. Easy operation, low maintenance cost

2. Detailed Images of Stud & Track roll forming a line

Machine Parts

1) Stud & Track roll forming line leveling device

Brand: BMS Original: China

2) Stud & Track roll forming line hydraulic pre-cutter

Brand: BMS Original: China

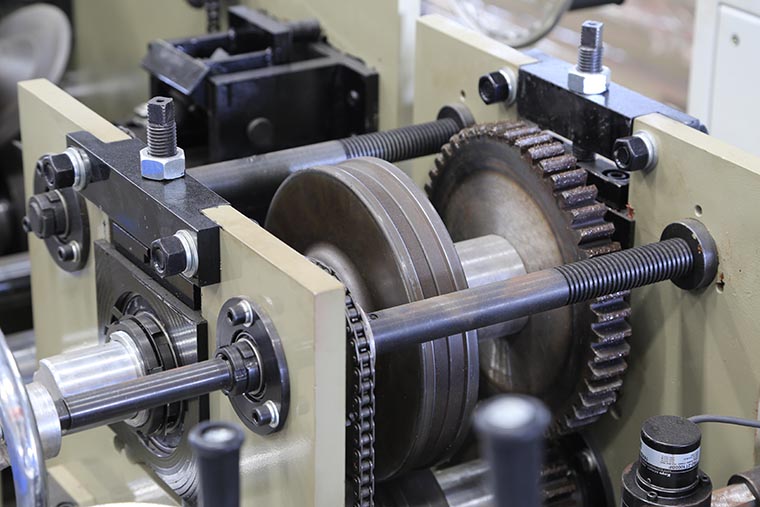

3) Stud & Track roll forming line rollers

Brand: BMS Original: China

Rollers manufactured from high quality bearing steel GCr15, CNC lathes, Heat Treatment.

with black treatment or Hard-Chrome Coating for options.

With feeding material guide, body frame made from 400# H type steel by welding

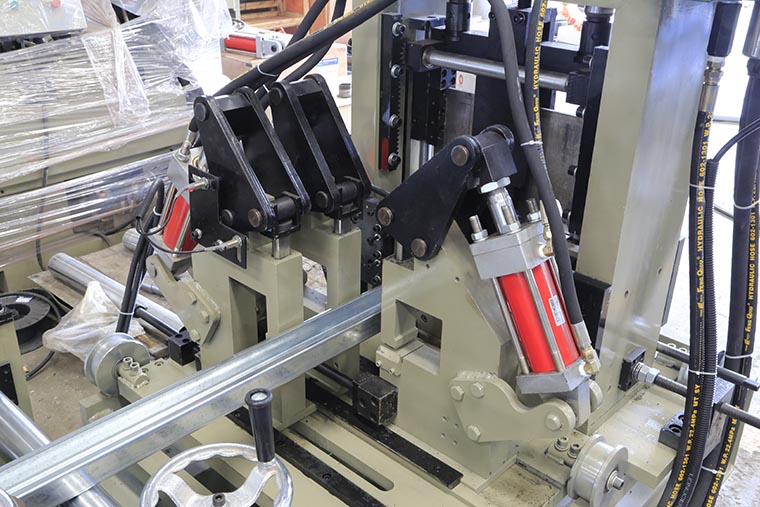

4) Stud & Track roll forming line post punching system

Brand: BMS Original: China

with 3 cylinders (one cylinder for a single hole and 2 cylinders for dual-holes.

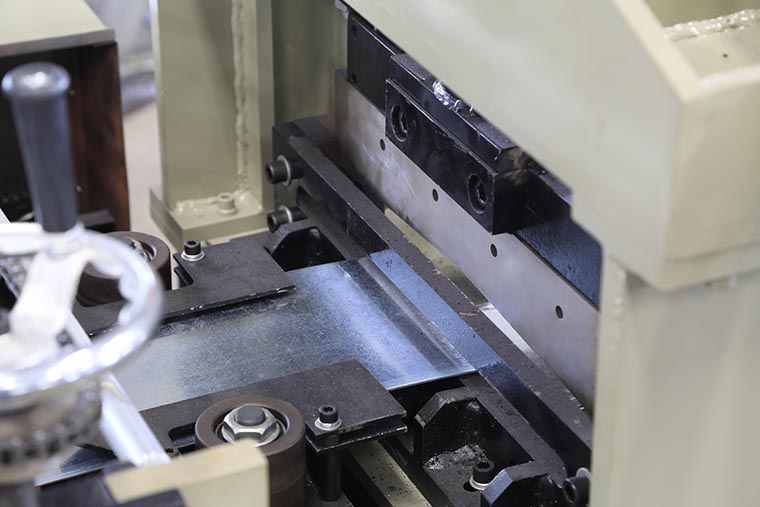

5) Stud & Track roll forming line post cutter

Brand: BMS Original: China

No need to change cutter for a different size,

made by high-quality mold steel Cr12 with heat treatment

Cutter frame made

from high quality 30mm steel plate by welding

Pre-punching &

Pre-cutting, stop to punch, stop to cut

hydraulic

motor:7.5KW, Hydraulic pressure range: 0-16Mpa

6) Stud & Track roll forming line exit rack

Brand: BMS Original: China

Un-powered, two units

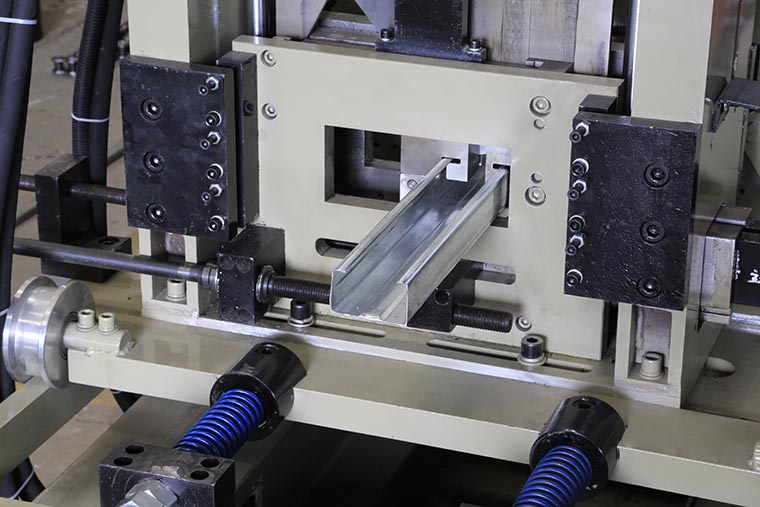

7)Stud & Track roll forming line product show

Brand: BMS Original: China

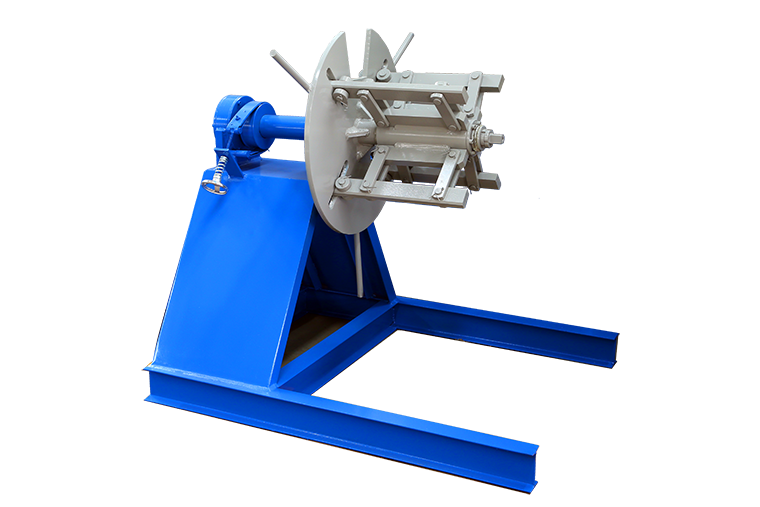

8) Stud & Track roll forming line decoiler

Brand: BMS Original: China

Manual Decoiler: one set

Un-powered, manually control steel coil inner bore shrinkage and stop

Max. feeding width: 500mm, coil ID range 470mm±30mm

Capacity: Max. 3Ton

With 3 tons hydraulic decoiler for option

Other detailes of Stud & Track roll forming a line

Suitable for material with thickness 1.0-2.0mm

Shafts manufactured from 45#, Main shaft diameter=φ80mm, precision machined

Motor driving, Gear chain transmission, 16 rollers to form and 7 rollers for straightening and leveling

Main motor=15KW, Frequency speed control. Forming speed of approx.18m/min

PLC Control System (Touch screen brand: German Schneider Electric/Taiwan WEINVIEW,

Inverter brand: Finland VOCAN/Taiwan DELTA/ALPHA, Encoder brand: Japan Koyo/OMRON)

Combined with: PLC, Inverter, TouchScreen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control Voltage 24V

User's manual in English

After-sale service of Stud & Track roll forming a line

1. The warranty for Stud & Track roll forming a line

is one year after the client receives the machine.

Within one year, we will courier the replacement parts to the client free of charge.

2. We offer technical support for the entire life of our machines.

3. We can send our technicians to install and train the workers in the clients' factories at extra cost.

Terms of trade

1. Minimum order quantity (MOQ): 1 piece

2. Delivery time: about 40 workdays

3. Port of loading: port of Xiamen

4. Type of payment: by T/T or by L/C

5. Export: Australia, UK, Ireland, Mexico, Brazil, Israel, Dubai, Russia, India, Taiwan, Singapore,

Malaysia, Thailand, Philippines, Myanmar, Vietnam, South Africa, Mozambique,

Zambia, Zimbabwe, Nigeria, Egypt, Sudan, etc.