Xiamen BMS Group |

|

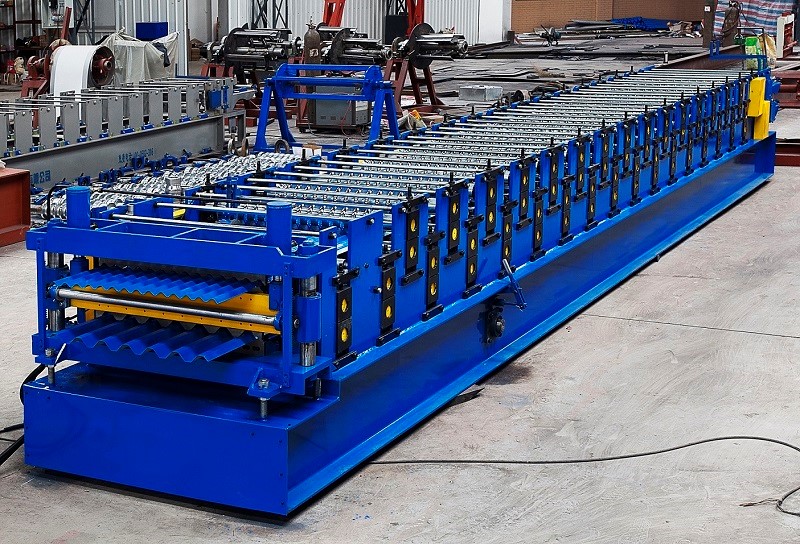

This machine takes GI/PPGI as raw material, through a series of steps and can produce the barrel type roofing sheets.

The inverter controls the motor speed, the PLC system controls length and quantity automatically, therefore, the machine achieves a continuous automatic production, which is the ideal equipment for cold roll forming industry.

TECHNICAL PARAMETERS FOR CORRUGATED PANEL ROLL FORMING MACHINE | |||

Serial Number | Item | Parameters | Remark |

Applicable material | Type | GI/PPGI | |

Thickness | 0.25-0.6MM | ||

Yield strength(Mpa) | G245-G550 | ||

Main performance parameters | Forming speed(M/MIN) | 12-20M/MIN | |

Machine size(L×W×H) | 9*1.5*2 | Refer to the machine | |

Power supply(KW) | 7.5+3.0 | Motor and Hydraulic Motor | |

MACHINE COMPONENTS FOR CORRUGATED PANEL ROLL FORMING MACHINE | |||

Name | Model/name | Quantity | Technical description |

Capacity: Max. 5Ton, hydraulic control steel coil inner bore

expanding, shrinkage and stop. | |||

Material Guiding System | 1 set | For feeding in the right position no Deviation. | |

Precutting Device | 1 set | Prevent the profile from being unbeautiful because of the rough

material. | |

Main Roll Forming Machine | 1 set | About 22 steps, motor driving, and chain transmission. Wall plate

structure. | |

3. Cutting system | Hydraulic Cutting Device | Precutting and post cutting both. | |

4. Hydraulic system | Hydraulic Station | 1 set | Providing the power of cutting. |

PLC Control System | PLC control system, encoder positioning, and cut-to-length

automatically, touch screen operating. | ||

6. Racking system | Exit rack | 3 PC | no power. |

1) We use Taiwan's quality.

2) Adopting advanced world famous brand components in computer parts. Like Siemens, Schneider, Sony, etc.

3) Running in a high automatization and intellectualization, no pollution.

Name: Rollers

Material: Imported first grade 45# steel.

Treatment process: CNC precision machined, heat treatment

hard Chrome Coated; And at last mirror-surface treatment for anti-rust, long service life and beautiful.

Name: Manual precutting device

Feature: Connecting with the PLC control system.

Once the material is required to change or the production is nearly finished, the PLC would alarm and you just need to pull the device to finish the cutting. easy operation and save your time.

Name: Double cylinder cutting structure

Feature: Unlike other factories in China, we adopt the double

cylinder cutting structure. to ensure the balance during the

cutting process, thus, a more stable and longer service life.

Name Post cutting Device.

Feature: Two cutting blades, stop to cut, cutting model: Cr12mov.

Driving by hydraulic power.

With two pillars support to make the cutting processing more stable, no shake.

Before loading the machine in the container, we clean the machine

first and cover it with a film.

and fix the machine stable and tightly by Steel wire rope in the

container, thus, for the machine safe, no moving.

BMS Machine (formerly named as HF BRAND FORMING MACHINERY CO., LTD) was established in 1996, which covers an area of MORE THAN 20000 SQUARE METERS. With 20 YEARS PROFESSIONAL EXPERIENCE, we have been the TOP 3 manufacturer and exporter of cold roll forming machines in China. We are an ISO9001 approved company and have European CE certification (issued by SGS). We have the honor to serve some of the famous companies in the world such as TATA STEEL, BLUESCOPESTEEL, BRADBURY MACHINERY, etc.

We manufacture wide range products of metal sheet cold roll forming

machines as follows: 1) for Metal Building Industry/PEB

(Pre-Engineering Building): HAYES style quick change CZ purlin

machine(including automatic and quick-change type C purlin machine

and Z purlin machine), light gauge steel framing machine(LGSF,

Howick and SCOTTSDALE style), roof panel forming machine,

corrugated panel roll forming machine, curving machine, glazed tile

roll forming machine, floor decking machine, ridge cap roll forming

machine, cladding facade system forming machine, cut-to-length

slitting line, etc., as well as some hydraulic shearing machine,

hydraulic folding machine for gutter and flashing, etc.