Jiangyin Dingbo Technology Co., Ltd |

|

Verified Suppliers

|

|

Product Descriptions

Introduction: The roller shutter door roll forming machine is a specialized piece of equipment that is designed for the sole purpose of producing essential components used in the manufacturing of roller shutter doors. These types of doors are commonly utilized in various settings, such as industrial, commercial, and residential, for their ability to provide security, privacy, and weather protection. The roll forming machine is a vital tool in the process of shaping metal sheets into the specific profiles needed for the assembly of roller shutter doors.

Function: As its name suggests, the roller shutter door roll forming machine has the primary function of forming metal sheets into the necessary components required for producing roller shutter doors. This process involves the use of rollers and dies that shape and cut the metal sheets to precise measurements. The machine also allows for customization, as different profiles and sizes can be achieved to meet the specific needs of different roller shutter door designs.

Usage: The roller shutter door roll forming machine is widely utilized in various industries and applications due to the ever-increasing demand for roller shutter doors. In industrial settings, these doors are commonly used for secure storage, while in commercial settings, they are often used for entranceways and storefronts. In residential settings, roller shutter doors are used for garages, patios, and windows. As a result, the roll forming machine is an essential tool for manufacturers looking to meet the high demand for roller shutter doors.

Benefits: The use of a roller shutter door roll forming machine offers multiple benefits. By being able to produce the necessary components in-house, manufacturers can control the production process, quality, and costs, resulting in more competitive prices for consumers. Additionally, the machine's precision and efficiency lead to consistent and accurate results, resulting in high-quality roller shutter doors. This not only improves customer satisfaction but also helps to maintain the manufacturer's reputation in the market.

Conclusion: In conclusion, the roller shutter door roll forming machine is a specialized equipment designed to produce the components necessary for manufacturing roller shutter doors. Its crucial role in shaping metal sheets into specific profiles allows for customization, making it a valuable tool in various industries and applications. Through its precision and efficiency, the machine offers benefits, such as cost and quality control, ultimately contributing to the production of high-quality roller shutter doors. Overall, the roller shutter door roll forming machine plays an essential role in meeting the demand for roller shutter doors within the market.

Features:

A shutter door roll forming machine, also referred to as a roller shutter door roll forming machine, is a highly efficient machine designed for producing components used in shutter or roller door systems. This machine is equipped with a variety of features that aid in its efficient operation. The specific features may differ from one manufacturer and model to another, but some of the most widely used ones are:

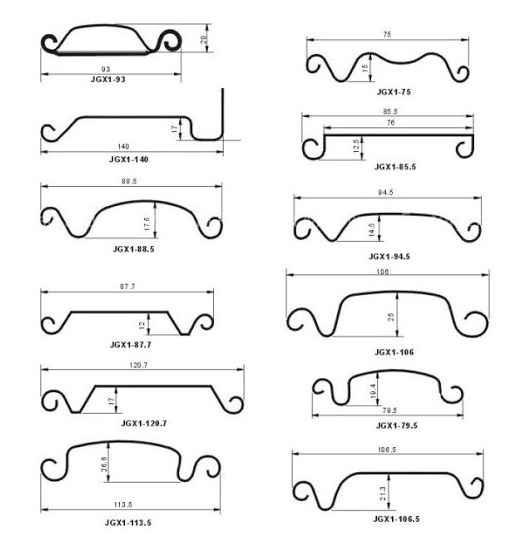

Version to design

Working Flow

Uncoiler --Punching -- Roll forming-- Hydraulic cutting -- Output table

Product Parameters

| Item | Parameters |

| Coil thickness (mm) | 0.8- 1.2 mm |

| Speed (m/min) | 10- 15 |

| Transmission type | Chain |

| Roll stations | 13 |

| Main power (Kw) | 5.5 |

| Main shaft (mm) | Ø 56 |

| Cutter material | Cr12MOV |

| Cutting accuracy | ± 1.5mm |

| Hydraulic station power (Kw) | 3 |

| Control system | PLC |

Main Components

| No. | Name | Qty |

| 1 | Manual uncoiler | 1 |

| 2 | Hydraulic Punching | 1 |

| 3 | Main Roll Forming Machine | 1 |

| 4 | PLC Control Box | 1 |

| 5 | Hydraulic Pump Station | 1 |

| 6 | Output Table | 2 |

Pictures

Application

Shutter doors, also known as roller shutter doors, are highly sought after for their versatility, security features, and ease of operation. They have a wide range of applications across various industries and settings. Here are some common uses for shutter doors:

Shutter doors are commonly used in commercial and industrial warehouses to provide easy access for loading and unloading goods. Their durability and security features make them ideal for protecting valuable inventory.

In retail stores, shutter doors are used to secure entrances and windows during non-business hours. They can also be used as a barrier between different sections of the store for added security.

For homeowners and mechanics alike, shutter doors offer a convenient solution for securing garages and workshops, providing easy access for vehicles and equipment.

In large shopping malls or centers, shutter doors can be found at the entrances and exits, providing a secure barrier when the stores are closed. They can also be used for storefronts to protect against break-ins.

In residential areas, shutter doors serve as a convenient and secure option for garage doors. They can also be found on windows for added protection against intruders.

Industrial manufacturing facilities often use shutter doors to control access between different areas of the building, as well as to secure large machinery and equipment.

FAQ

1. Q: What's the warranty period? (24hours online)

12 months warranty period, starting from the date of the successful installation and commissioning of the equipment at the Buyer’s Installation site. During which all parts damaged because of quality problem will be changed for free.

2. Q: Do you have installation and commissioning service?

A: If buyers come to our factory to inspect, the training to install and operate is provided face to face. If not, manual and video is provided to show how to install and operate.

B: If buyer need we will send technician to buyer site to do installation and commissioning and training.

C: installation and commissioning cost: One engineer will visit Buyer’s workshop for installing, commission and training. The buyer has to pay USD100 per day and visa fee, air tickets fee, accommodation and food, necessary communication, etc.

(Normally ,It takes about a week to install )

3. Q: What’s your after-sales service ?

We provide 24-hour online service for our customers.

And we are happy to give advice and also have skilled technicians available to maintain the machine overseas to customers’ workshop if needed.

4. Q: What's your delivery time ?

Normally we can finish production and testing within 45-70 days after receiving deposit. Some machines in stock, can be delivered at any time

5. Q: You are trading company or factory?

We are Manufacturer, and we export our machine by ourselves.

6. Q: Do you provide customized machine?

Sure, we can design the machine according to the requirement and profile drawing you provide. Our engineers can offer the best professional solution to our worldwide clients.

7. Q: How to visit your factory?

We are in jiangyin city,belongs to Jiangsu province, near Shanghai. If you

arrive at Shanghai Airport,we can pick you up(It is 160 kilometers from

Pudong Airport, about 3 hours.

It's 110 kilometers from Hongqiao airport, about 2 hours; It's 125 kilometers from downtown Shanghai about two and a half hours.

It is very convenient.Please let me know if you have booked the tickets

so that I can prepare and book a hotel for you,we will arrange for car to pick you up.

By high speed train from Shanghai to East Wuxi (Wuxi Dong station), half an hour.

8. Q: How to place order ?

Inquiry---confirm the profile drawings and technical specification and price--- confirm the PI--- arrange the deposit or L/ C--- start production-- do inspection--- Shipment

9. Q: What certificate do you have ?

We have CE and ISO certificate.

10. Q: What are your terms of payment ?

First payment: 40 % by T/ T, second payment: 60% by T/ T, after the successful inspection at seller’s workshop, and before delivery.

11. Q: What can you do if the machine breaks down?

We have 12 months warranty period, if the broken parts can not be repaired, we will send new parts to replace the broken for free.But if the warranty period is over,you need to pat the express fee.We can solve problems through negotiation and provide technical support for the whole life of equipment .