Sichuan BENO Energy Conservation and Environmental Protection Technology Co., Ltd. |

|

Verified Suppliers

|

|

Jaw Rock Crushers are powerful machines used for crushing hard materials in various industrial applications. They are designed based on a single pendulum design, which is known for its reliability and efficiency in the crushing process.

The principle behind the operation of a Jaw Rock Crusher is relatively simple. The crusher is suspended from the mandrel and can swing from side to side. When the eccentric shaft rotates, the connecting rod enables the jaw to move in an up and down reciprocating motion. This motion drives two thrust plates, leading to a left and right reciprocating motion of the jaw, ultimately achieving the crushing and discharging of materials.

One of the key advantages of the Jaw Rock Crusher is its crank double linkage mechanism. This mechanism ensures that while the moving jaw experiences significant crushing reaction force, the eccentric shaft and connecting rod are not subjected to excessive forces. As a result, the Jaw Rock Crusher can be manufactured in large and medium sizes, making it suitable for crushing hard materials in various industries.

The Jaw Rock Crusher excels in its ability to crush large materials and transform them into medium-sized particles. This is particularly important in engineering projects where graded gravel is required. By efficiently breaking down large materials, the crusher facilitates the production of materials that meet the specified engineering requirements.

In summary, the Jaw Rock Crusher is a reliable and efficient crushing machine used in various industrial applications. Its single pendulum design, crank double linkage mechanism, and ability to process large materials make it a valuable tool in industries such as infrastructure construction and mining.

Technical Reference Data

| Model | Feed port size (mm) | Maximum feed particle size (mm) | Adjustment range of outlet (mm) | Production capacity (t/h) | Power (kw) | Rotating speed (r/min) | Weight (t) |

| XCE2540 | 250*400 | 210 | 20-80 | 5-20 | 15 | 300 | 2.8 |

| XCE4060 | 400*600 | 340 | 40-100 | 16-54 | 30 | 275 | 6.5 |

| XCE5075 | 500*750 | 425 | 50-100 | 30-85 | 55 | 275 | 10.3 |

| ※XCE40108 | 400*1080 | 340 | 40-100 | 30-100 | 75 | 250 | 10.8 |

| ※XCE5013 | 500*1300 | 425 | 50-120 | 50-150 | 90 | 275 | 15.6 |

| ※XCE5015 | 500*1500 | 425 | 50-120 | 60-185 | 110 | 275 | 18.3 |

| ※XCE5712 | 570*1200 | 475 | 50-130 | 80-210 | 132 | 275 | 17.8 |

| XCE6090 | 600*900 | 500 | 65-160 | 50-150 | 75 | 250 | 15.5 |

| XCE75106 | 750*1060 | 630 | 80-140 | 50-208 | 110 | 250 | 27.5 |

| XCE9012 | 900*1200 | 750 | 95-165 | 100-238 | 132 | 200 | 50 |

| XCE1012 | 1000*1200 | 850 | 105-175 | 295-350 | 160 | 200 | 52 |

| XCE1215 | 1200*1500 | 1020 | 150-300 | 300-800 | 220 | 180 | 100.8 |

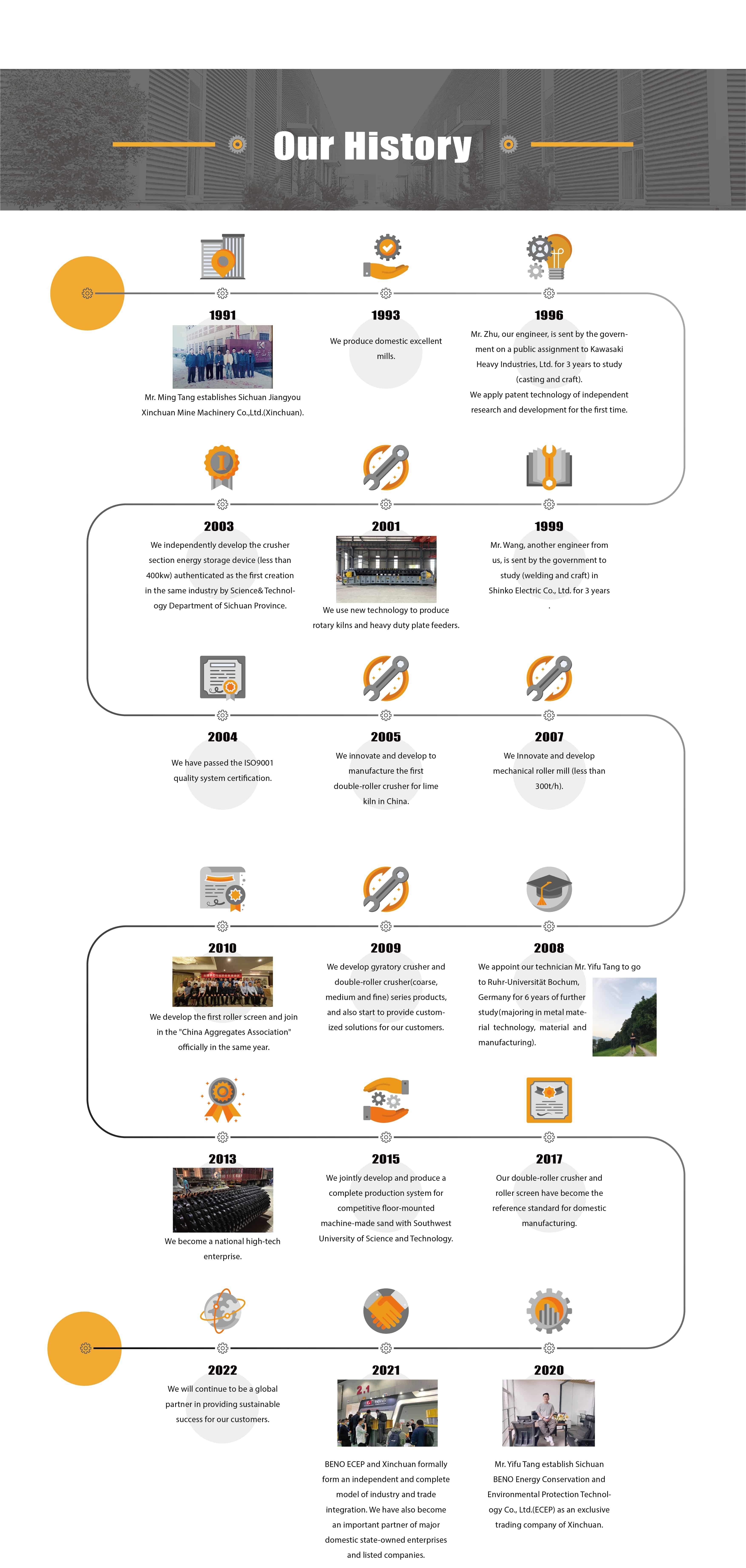

Our History