Qingdao TaiCheng transportation facilities Co.,Ltd. |

|

Verified Suppliers

|

|

Ethylene Vinyl Acetate Copolymer Metal Beam Crash Barrier Roller

Safety Barrier Box Beam Guardrail

As a new type of guardrail, the rotating tunnel entrance guardrail

has been used in recent years. The main component of the rotating

barrel is a flexible material made of polyethylene and EVA

(ethylene vinyl acetate copolymer), which can be used as a

longitudinal energy-absorbing structure. In the process of

collision between the vehicle and the guardrail, the rotating

barrel can drive the vehicle through its own rotation, reducing the

collision angle between the vehicle and the guardrail, thus

reducing the lateral force generated in the process of impact. The

rotating guardrail turns the sliding friction between the normal

guardrail and the vehicle into a smaller rolling friction. The

rotating tunnel entrance guardrail not only reduces the

acceleration of each component of the collision vehicle, reducing

the injury to personnel and reducing the degree of vehicle

deformation, but also reduces the collision time and increases the

vehicle exit speed. In addition, it reduces the vehicle's handling

resistance in a collision, helping the driver to operate the

vehicle quickly away from the guardrail to complete the guidance.

Rotating guardrail in the collision barrel colour setting can be

customized according to the needs of red, yellow or other colours,

to form a visual impact on the driver, with excellent guidance

function.

The rotating guardrail is mainly composed of column, swing circle,

rotating barrel, cross beam, waveform beam, reflective strip and

corresponding connecting parts. The rotating barrel is made of a

composite material of ethylene vinyl acetate copolymer (EVA) and

polyurethane, which is elastic, impact resistant and wear resistant

and can effectively prevent the rotating barrel from being

shattered upon impact. The resilience of the barrel also ensures

that it can be quickly restored to its original state after a

severe impact. The barrel chosen by Suzhou Bypass Expressway Co.,

Ltd. is orange, which has a high brightness reflection effect and

eye catching function, which can effectively improve the driver's

attention and reduce the incidence of accidents, thus ensuring the

safety of vehicles.

Features

(1) Fast opening.

The pluggable and removable structure enables 12 m (2 sections) to

be opened and pushed in 3 minutes in case of emergency, far better

than the norm of 10 m in 10 minutes.

(2) Safety upgrade.

Through rotational friction, the instantaneous impact energy is

transformed into rotational energy and friction energy, effectively

reducing the damage to the vehicle and the degree of injury to

personnel.

(3) Material saving.

The simple shape of the product greatly saves material costs, using

about 78 kg of material per linear metre, which is 50% to 80% of

the material used in similar products in the current market.

(4) Beautiful shape.

The beautiful shape and beautiful rotating barrels have a good

sight line guidance function, which can improve the road appearance

and effectively ease the

The effect is more obvious especially at night and in rainy days.

(5) Easy to install.

The compact design of the product allows for easy installation on

site after the unit has been assembled, greatly reducing the time

spent on site and effectively reducing the risk of road-related

operations.

(6) Simple maintenance.

The rotating bucket is made of EVA composite material, which is

resistant to chemical corrosion, ageing and weathering, and is not

easily damaged by vehicle impact, and does not need to be replaced

during its service life (10 years).

Production Qualification And Test Report

Product Components And Specifications

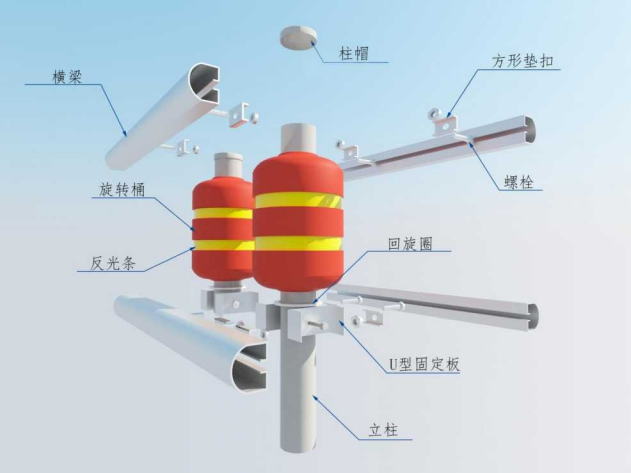

The rotary anti-collision guardrail is composed of rotating barrel,

beam, column, reflective strip, casing, rotating coil and

connecting piece.he exploded view is as follows:

Rotary anti-collision guardrail constitutes the outline - the

deviation of the outer dimensions of the rotating anti-collision

guardrail member is allowed 5%

| d | 151+2 -2 |

| h1 | 110+2 -2 |

| h2 | 50+1 -1 |

| h3 | 80+2 -2 |

Production Capacity

For the new rotating bucket guardrail, our capacity is 12-15km per

month , which can meet the requirements of all urgent orders.

Shipping Details

| No. | Product Specifications | 40*HQ Container Shipping Capacity |

| 1. | 1000 mm Column Space Barriers size : 350*500 MM | 280 Meters |

| 2. | 700 mm Column Space Barriers size : 350*500 MM | 240 Meters |

How safety roller barrier works?

1. The roller barrier converts great shock from vehicle collision to rotational energy to absorb shock.

2. Upper and lower frames adjust tires of large and small vehicles to prevent the steering system function loss.

3. The three-dimensional structure of D-shaped frame and buffering bracket distribute and absorb the 2nd shock.

4. Props at an interval of 0.7 m increase bearing power to prevent accident vehicles from going over the guardrail and turning over into a dangerous area.

5. The product has a rotating barrel made of EVA with excellent shock absorption power, three-dimensional buffering frames and dense props supporting the frames.

Minimum Setting Length of Rotary Collision Guardrail

| Highway grade | Set separately(m) | Lap setting(m) |

| Highway, First Class Highway | 70 | 15 |

| Grade two highway | 48 | 10 |

| Level 3 and 4 Highways | 28 | 5 |

The rotating guardrail is mainly composed of column, swing circle,

rotating barrel, cross beam, waveform beam, reflective strip and

corresponding connecting parts. The rotating barrel is made of a

composite material of ethylene vinyl acetate copolymer (EVA) and

polyurethane, which is elastic, impact resistant and wear resistant

and can effectively prevent the rotating barrel from being

shattered upon impact. The resilience of the barrel also ensures

that it can be quickly restored to its original state after a

severe impact. The barrel chosen by Suzhou Bypass Expressway Co.,

Ltd. is orange, which has a high brightness reflection effect and

eye catching function, which can effectively improve the driver's

attention and reduce the incidence of accidents, thus ensuring the

safety of vehicles.

Highway Anti-collision Polyurethane Rotating Barrier Advantage

1.Widespread flexibility.

Completely suitable for all weather conditions, the Polyurethane foam safety roller barrier can be installed in the median between opposing traffic flows, on curved median strips, curved ramps, diverging points, curved downhill corners, hillside locations, school zones and in danger zones, protection zones for posts, street lights and general infrastructure within the road reserve.

2.Cost efficient lifecycle.

The lifecycle cost of the Polyurethane foam safety roller barrier out performs traditional crash barrier systems as it requires less frequent repair, replacement and maintenance. More significantly the Polyurethane foam safety roller barrier provides reduced occupant risk of injury.

The cost benefit of the Polyurethane foam safety roller barrier makes it an irrefutable crash barrier solution comparing it to other semi ridged barrier systems.

3.Pure innovation.

Shock absorbing system

Converts shock energy to rotational energy

Decreases speed impact

Redirects vehicles back into its lane

Prevents driver and passenger fatalities

Flame retardant and easy to install

Visually stands out to alert drivers