Guangzhou Chunke Environmental Technology Co., Ltd. |

|

100LPH With Chemical Dosing Adding Type Brackish Water Treatment Reverse Osmosis Systems

Product Description

Reverse osmosis systems are used to reject bacteria, sugars, proteins, particles, dyes, and other

constituents that have a molecular weight of greater than 150-250 daltons from tap and brackish water.

It is also capable of purifying water and remove salts and other impurities. Our largest tap and brackish

water units, the CK-BW series, comes standard with media pre-filters, chemical dosing, and antiscalant.

These systems can be customized to fit individual customer and water application needs. The CK-BW

series has a capacity of 250LPH to 600.000LPH.

Our largest tap and brackish water units, the CK-BW series, can come standard with media pre-filters,

chemical dosing, and antiscalant. These systems are usually customized to fit individual customer and

water application needs, and is considered to be one of the most compact industrial reverse osmosis

systems in the market, it also features state of the art energy saving membranes.

When we design the CK-BWseries industrial reverse osmosis plants,

we consider robust construction,

user-friendly design, environmentally conservative operations, and

long term reliability.

Economical and efficient, CK-BW industrial reverse osmosis

equipment incorporate the latest in RO

technology to remove

dissolved minerals, particles, organics, solids and other contaminants from water. Reverse Osmosis uses

RO membranes as its core separation technology to reject these contaminants. CHUNKE use the most reputable membranes manufacturers such as Dow Filmtec and Hydranautics (USA made)

Industrial Reverse Osmosis System RO Water Purifier plant includes multimedia prefilter, water softener

or antiscalant dosing system, dechlorination dosing system, reverse osmosis unit with semi-permeable membranes, and UV sterilizer or post chlorination as a post treatment. These machines apply the technology

of reverse osmosis by transporting feed water through multimedia prefilter to remove particles that are larger than 10-micron. Then the water is injected by an antiscalant chemical to control hardness fouling that may

cause damage to the membranes within the machine. These pretreatment options have the capability of removing hardness, chlorine, odors, color, iron, and sulfur. The water then continues into the reverse

osmosis unit where a high-pressure pump applies extreme pressure to the highly concentrated solution, separating the remaining salts, minerals, and impurities that the pre-filter cannot catch. Fresh, potable

water comes out from the low-pressure end of the membrane while salts, minerals, and other impurities

are discharged into a drain on the other end. Lastly, the water is passed through a UV sterilizer (or post chlorination) to kill any bacteria and microbes that still exist in the water.

How RO system works ?

A) Pre-Chlorination Dosing System

If the feed water contains traces of heavy metals or contaminated,

it is high recommended to dose some

chlorine to change the dissolved heavy metals to physical form, the media filter will be able to filter most

of it.

B) Raw Water Storage Tank

Although some RO Systems can draw water right out of a well or pipe

feed, most systems start with a large

tank that stores the contaminated water. Not having enough feed water can damage a pump, so having a

large storage tank for your intake water is an easy way to make

sure your pump lasts for as long as possible.

C) Feed Water Pump

A commercial or industrial pump provides the initial pressure for the Treatment System. This motor usually

provides enough water pressure to get through any pretreatment as well as the RO membranes, but if it

doesn't a booster pump may be necessary farther down the line.

D) Multi-Layer or Media Filter

As much as we hate to admit it, there are some things that

membranes can't purify. Nitrates, a common

contaminant found in fertilizers and animal waste, are a good example of particles that dissolve too well

in water for reverse osmosis to catch them. Things like foul odor and taste usually aren't prevented by

reverse osmosis, either. A Multi-Layer filter can be filled with media that specifically targets the things

your RO System can't catch. If you need to eliminate these contaminants, a Multi-Layer Filter is a must.

An example of MMF or multi media filters is our CK-1 Series.

E) Activated Carbon Filter

Activated carbon filters are good solution to reduce organic, bad

taste, smell and chlorine from the water.

F) Automatic Water Softener

Automatic water softeners are designed to remove water hardness,

calcium and magnesium ions, for small

RO systems, we usually recommend water softeners instead of the antiscalant chemical dosing.

G) Antiscalant Chemical Dosing System

For larger RO systems, we use antiscalant dosing systems to dose

our antiscalant RO chemical, which helps

in preventing membranes fouling.

H) Reverse Osmosis System

We finally have our Reverse Osmosis System. If a booster pump is

necessary, it will typically be just before

this step. The Reverse Osmosis System can produce up to one million gallons of product water a day from

a steady intake, as well as a sizable amount of waste. Usually the waste water can be dumped down the

drain, but check with your local water authorities in case it needs to be handled with care.

I) Product Water Storage Tank

The permeate from the RO purification system will usually go to a

large tank, where it is held for use. If it didn't,

the system would need to be running in order to have access to fresh water, which can be inconvenient.

Sometimes, an RO treatment System pumps water directly into a well or aquifer for recharging instead of

being used in many of the normal industries or applications it is used in.

J) Post-Chlorination Dosing System

If the permeate water is intended to be stored for more than one

day, it is highly recommended to dose some

chlorine to maintain clean and non contaminated water.

K) Product Water Pump (Re-pressurization)

This pump repressurizes the permeate water to the point of use

ends. This is selected based on the overall

travelling distance and required head. This pump must be selected in stainless steel to prevent any

contamination to the permeate water.

L) Product Water UV Sterilizer

The UV sterilizer is placed after the storage tank, and as a final

disinfection device. Most of the time, we

either use post chlorination as a disinfectant agent, or ultraviolet sterilization.

Consumable replacement cycle

| NO. | ITEM | Replacement cycle |

| 1 | Pure water silica sand | 2~3years |

| 2 | Pure water activated carbon | 1~2years |

| 3 | Filter cartridge | 2~3month |

| 4 | RO membrane | 2~3years |

FAQ

Q: Are you trading company or manufacturer ?

A: Yes, we are a manufacture with designing, manufacturing,

marketing and exporting.

Q: What's the information you need to know before order?

A: what's your raw water ?

B: what's the capacity per hour of the equipment ?

C: What’s the application of purifier water ?

Q:Which machine should I choose?

A:It depends on your raw water quality ,pure water requirement and the water production you need

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 40% T/T in advance ,60% TTbalance before shipment.

Q: How long is your delivery time?

A: Generally it is 15-30 days, Depends on your project.

Q:How can you control the quality and delivery?

A:All our machines will be tested before packaging. wooden packing

is strong and safety for long delivery.

Q:What’s your warranty?

A:Our warranty is 1 year. But normally, our machine can work 5

years before repair.

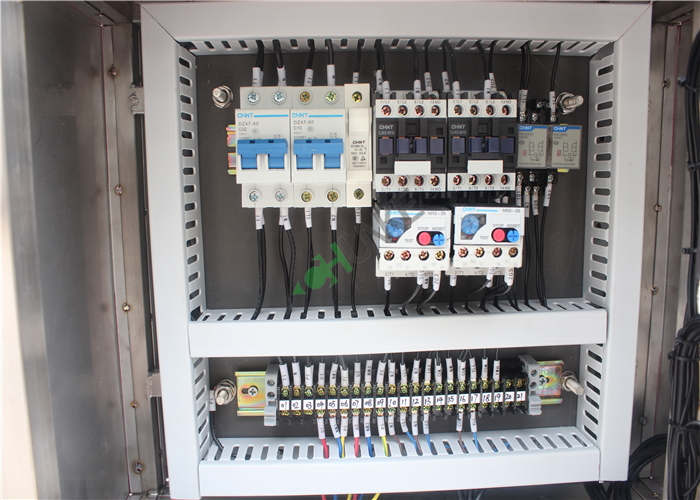

Detail Pictures