RKENS TECHNOLOGY CO.,LTD |

|

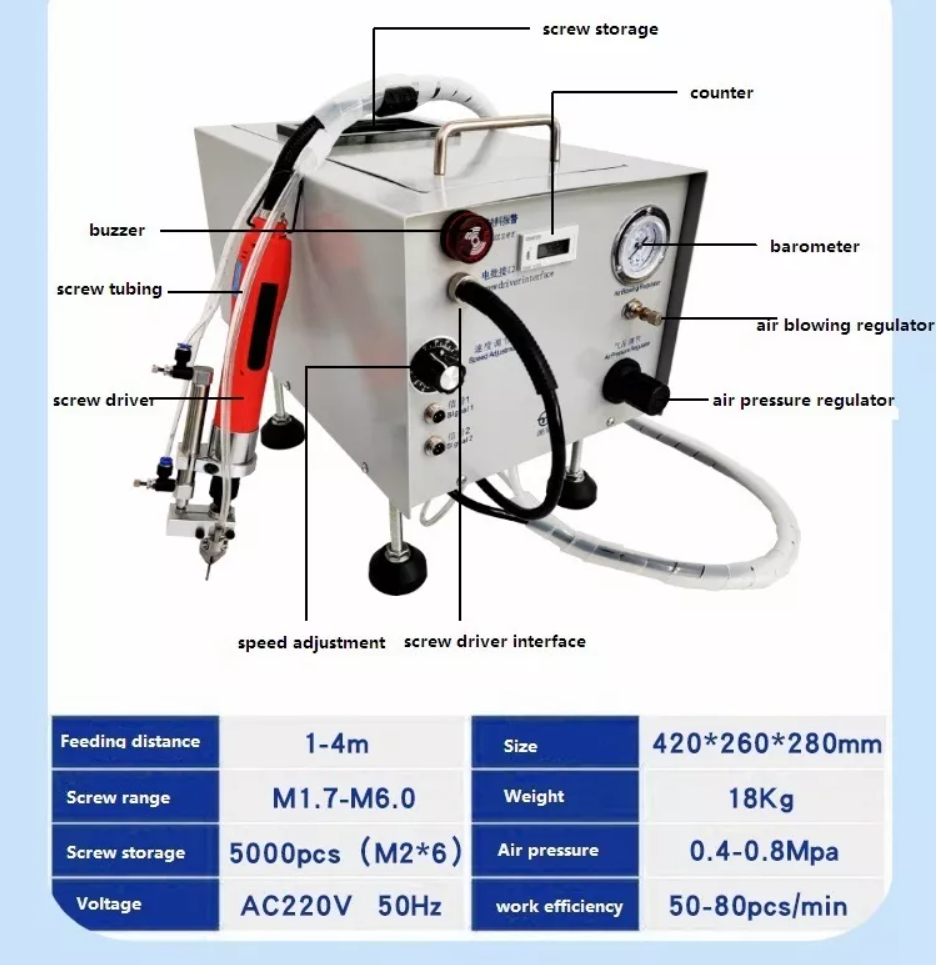

Main components:

Screw locking machine is made of 3 main parts: 1.Screw feeding system. 2. Screw sorting system. 3. Screw locking system.

These 3 systems are controlled by the machine's program.

Hand-held automatic locking screw machine feeds screws in a turbine way and order screws on a vibration guide rail, and transport screws to Screw Sorting System through magnetic resonance, then sort one screw per time and send it to screwdriver nozzle, finally electric or pneumatic screwdriver will lock the screw into products.

If you are interested in this screw feeding and tightening machine, please tell me your screw size.See picture below.

Features

1. Automatic screw feeding, sorting and locking for various shapes screws. One-hand operation.

2. Torsion precision and convenient adjustment, ensure the quality of screw locking

3. Turbine feeding, low volume and noise, convenient maintenance. Light weight and small, mobility and save space.

4. Warning function when lack of screws.(Acousto-optic alarm)

5. High efficiency. No need to pick up screws, move screws and put screws. Just need to lock the screws aimed at the screw hole.

6. Sensor controls screws feeding one by one to avoid feeding repetition.

7. Can lock screws very fast, around lock 60 screw per minute.

Parameter

| Voltage | AC220V/110V 50HZ/60HZ |

| Working pressure | 2-3KGF/cm2 |

| Working efficiency | 50-70PCS/MIN(Depends on screw length) |

| Noise | Lower than 65db |

| Conveying distance | 1-4m |

| Hopper capacity | 5000pcs for M 2x6 screws |

| Size | L370*W250*H190MM |

| Weight | 23KG |

| Screw length | Less than 45mm |

| Suitable screws | M2.0-M6.0 |

| Automatic | Yes, Auto feeding, sorting and locking screws |

Working conditions

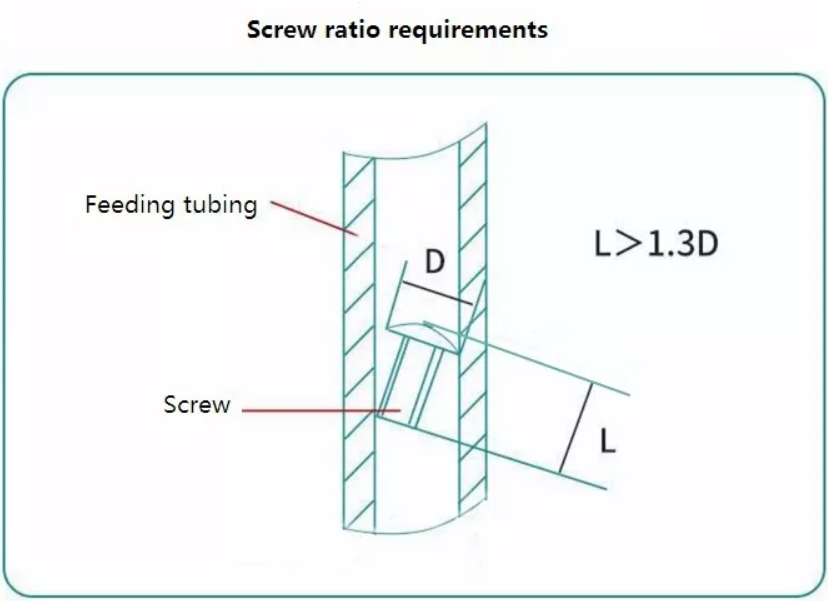

1, Screw specification requirements:

The screw length should be over 1.3 times greater than the screw

cap’s diameter.

If the screw cap is greater than the screw length, the screw cap may come out first, because the screw will turn over during feeding screws.

The screw length should be less than 45mm.

2, Product requirements:

No barrier within 3mm around the lock hole. The screwdriver nozzle

and the locked products should have a plane contact. There is

enough space for the screwdriver nozzle to press the screws into

locked products.