Dongguan Longxingjian Intelligent Equipment Co., Ltd. |

|

Verified Suppliers

|

|

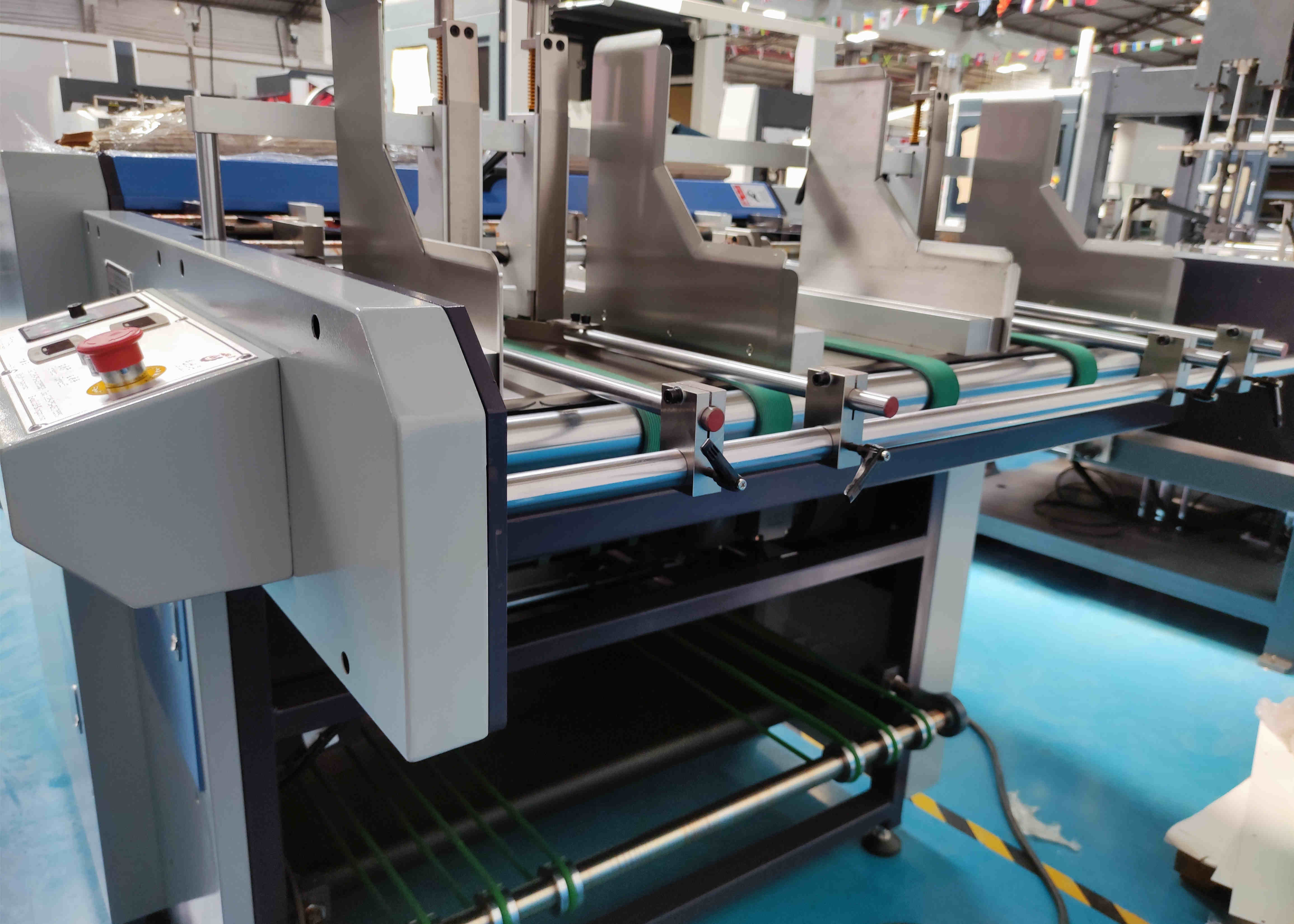

Automatic High Speed Cardboard Carton Paper MDF Board Grooving Machine

Fully automatic digital display slotting machine with high

performance, high stability, high accuracy, easier to operate. It

can be used for paper jam and gray board slotting. It is

indispensable for the front-end process of carton forming.

This machine uses a belt to automatically feed paper, and

transports it on one side to ensure accuracy, which solves the

instability factor of manual paper feeding. Belts are used to hold

the cardboard directly on the drum to ensure precision and speed

when grooving. This machine is suitable for making rigid boxes

1 Scope of application

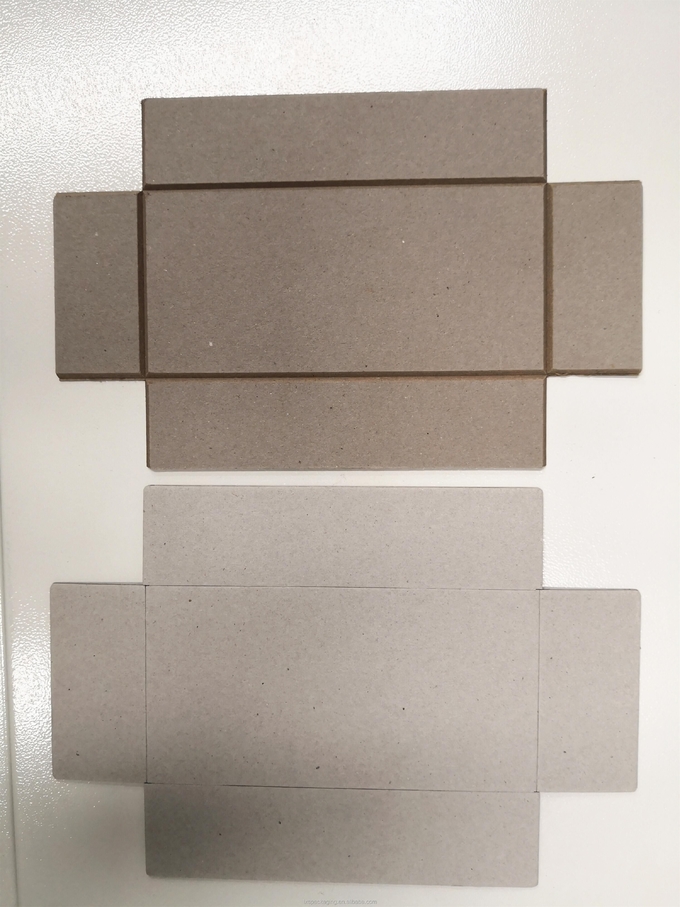

For gray board paper, mounted cardboard, MDF, two-way one-time

slotting.

2 main advantages

One machine can be used dually, with two-way slotting for the sky

and ground cover and one-way slotting for the leather shell. The

equipment can switch functions when needed.

The stability advantages of the product's semi-overlapping steering

mechanism: the first lane can be turned into a semi-overlapping

state when turning to the second lane, and the speed of the

steering part can be appropriately slower compared to the same

speed. The stability is improved without affecting the speed of the

whole machine.

Use of production leather shells: The belt computer setting of the

steering conveyor department can convey forward and reverse. When

producing leather shells, there is no need to go through the second

pass to produce the finished product. The steering belt is directly

set to reverse, and the first groove is sent directly to the

receiving machine.

Automatically collect finished products.

| Machine model | LS-1200B |

| Quantity of groove at a time | 8 slots |

| Working speed | 40m/min(100-200pcs/min) |

| Cardboard size | 140*120-1000*600mm |

| Cardboard thickness | 1-4mm |

| Motor power | 2kw/380v |

| Machine dimension | L2050*W1600*H1350mm |

| Machine weight | 1430kg |

Longxingsheng LS-1200B Energy Saving Cardboard Grooving Machine is the ideal choice for customers who need a reliable and efficient cardboard groover. With a minimum grooving size of 600mm and an accuracy of ±0.1mm, this grooving machine is no doubt the right choice for your business needs. It is also equipped with an automatic control system and high-accuracy roller. This ensures that the grooving machine operates in an energy-efficient and precision-oriented manner. The machine is also equipped with PLC controls, meaning that you can easily monitor the grooving process and make necessary modifications to ensure that the output meets your desired standards.

All orders of Longxingsheng LS-1200B Energy Saving Cardboard Grooving Machine come with a minimum order quantity of 1 unit, and all orders are packaged with film & wood case for protection.

The Board Grooving Machine will be packaged and shipped in a standard 5-ply corrugated box using the following procedure: