ED SiC Heater General Description:

Sic rod element, sic heating element

The SiC electrothermal element is a rod-shaped non-metallic

thermoelectric element which is made of high quality green SiC as

the main raw material through processing, high temperature

silicification and recrystallization.

Mingxin SiC heating elements feature hot zones of recrystallized

silicon carbide, optimized for resistance to oxidation and common

process gases. Available in rod or multi-leg designs.

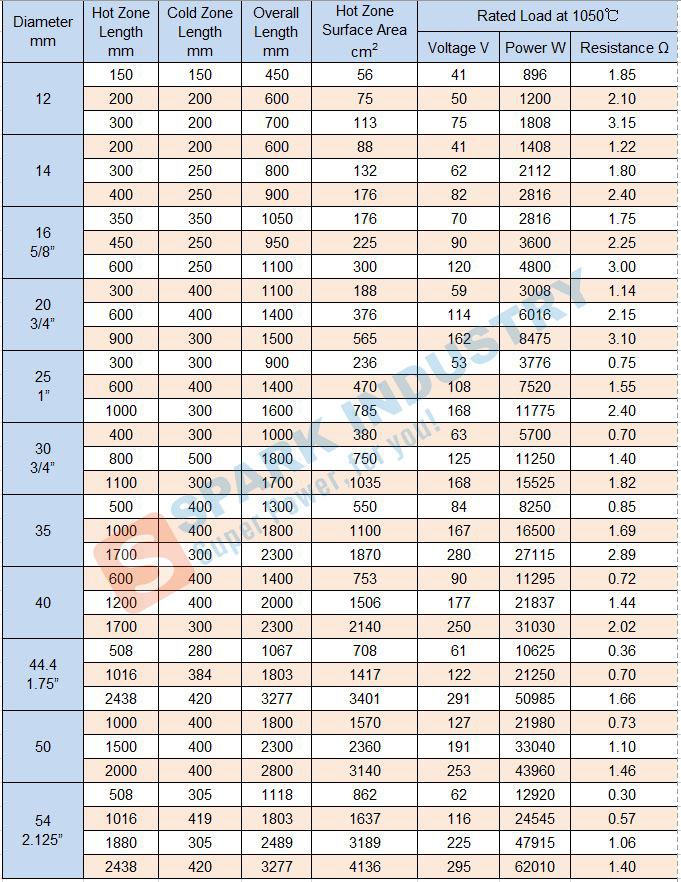

ED SiC Heater Parameters

series | Silicon carbide heating element |

model | Non-standard custom |

Product features and features | High temperature resistance, oxidation resistance, high density. |

Product specification | Non-standard custom |

Whether to accept customization | Accept customization and provide relevant customized content and

sample service |

standard packaging | Silicon carbide heating elements are packed in standard export

wooden boxes, inner foam sponges, outer wooden boxes and iron

spring suspension to ensure safety. |

ED SiC Heater application :

It is extensively used in the fields of metallurgy ,ceramics, glass

,machinery,analysis test semiconductor science and research

Advices of using heaters silicon carbide sic heating element:

1) In order to keep furnace temperature and the charges uniform of

each element, before installation resistance distribution must be

carried.

2) As the element is very brittle, be careful while install and

maintain to avoid any damage.

3) When start to operate the furnace, raise voltage slowly and

gradually, never give full load at one time.