Shenzhen Benia New Material Technology Co., Ltd |

|

Verified Suppliers

|

|

FORTRON 1115L0

| Glass Fiber Reinforced Flame Retardant |

FORTRON 1140L4 DW FORTRON 1140L6 DW FORTRON 4184L6 DW | Drinking Water Approved |

FORTRON 6150T4 DEV | Glass Fiber/Mineral Fiber Reinforced |

FORTRON® PPS Polyphenylene Sulfide:

If your design challenges are high temperature stability, extensive chemical resistance, high stiffness, high strength, and creep resistance at high temperatures, please consider choosing Fortron® PPS PPS. Fortron® PPS is a high-temperature resistant linear PPS with excellent size stability, self-flame retardant, and excellent chemical solvent resistance.The PPS is insoluble in any known solvent below 200℃, and it also shows excellent stability in both conventional and alternative automotive fuels.

The Fortron® PPS has standard injection molding grades for glass fiber and mineral enhancement or glass fiber / mineral blend enhancement, as well as many special grades, such as lubrication modification, low warping, fast molding, and other special performance improvements.Some Fortron® PPS grades meet ISO10993 and US Pharmacopoeia (USP) VI, and they are listed in the US Drug Master File (DMF 14844) and the US Medical Device Master File (MAF 1097).These grades also meet the European Directive 2002 / 72 / EC on food exposure and the BfR (Federal German Institute of Risk Assessment, formerly BgVV, Federal German Institute of Consumer Health Protection and Veterinary Medicine) standards.

Fortron® products have been designated for use in a wide range of

injection

molding, such as components under automotive engine cover plates,

drivetrain components, pumps, fuel system components,

surface-mounted electronic and electrical components, hair dryers

and pump components, protective non-adhesive coatings, medical

equipment and power tools.The Fortron® PPS is also a preferred

material for fuel cells and diesel vehicles because it can produce

membranes and composites for these applications by extrusion and

blow molding processes.

Linear Fortron® PPS can produce molten non-woven fabric using melt blowing and spinning bonding techniques.Fiber and fiber monofilaments produced by Fortron® PPS have been used for weaving or weaving transmission belts, flame retardant fabrics, and filter carriers.Seranis also offers non-filled, high viscosity Fortron® PPS products for extrusion and molding processes for the production of slabs, rods and other billets.These billets are usually used to process the samples.

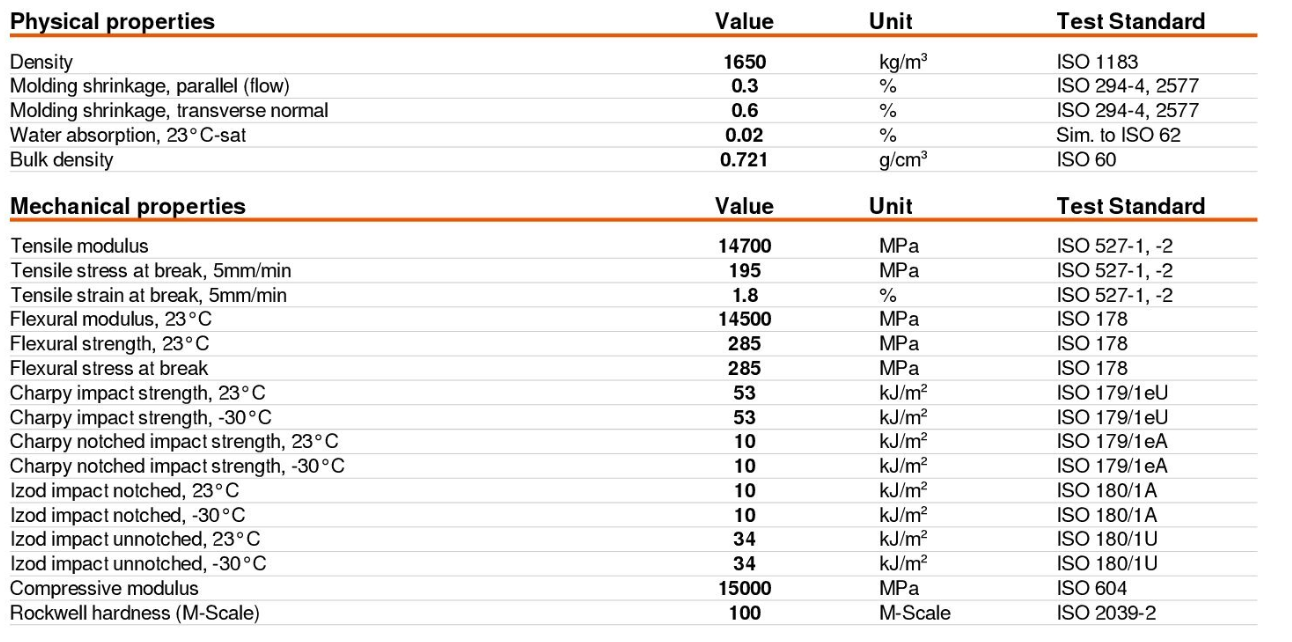

PPS Fortron 1140L4 is a 40% glass-reinforced grade that is the strongest and toughest

product available. It exhibits excellent heat and chemical

resistance, good electrical properties and is inherently

flame-retardant. The high hardness and rigidity at elevated

temperatures allows for good load bearing performance. This product

has good weldability due to the modest filler level.

Applications made of this grade are electronical components (i.e.

bobbins, lamp housings, brush holders) and various other components

requiring strength and resistance to aggressive chemicals (i.e.

automotive heaters, pumps, valves, fuel rails, microwave oven rings

and distillation column packings).

Feel free to contact us with any questions.

If you have any doubt about the price, we can give a proper discount by different purchasing quantity.

PRODUCT INFORMATION

Shenzhen Benia New Material Technology Co.Ltd., located in Shenzhen,China, is a professional supplier of high-temperature engineering plastics and special modified materials. Benia is committed to introducing, transforming and serving quality customers of thousands materials and advanced scientific and technological achievements around the world. At present, our customers cover aerospace, electronics and electrical, medical supplies and equipments, photoelectric communication, water treatment, transports, consumer products and other industries.

Benia provides not only customers with high quality and high performance products to meet the changing needs of customers, but also the abundant technica resources of various chemical plant to provide customers in the process of product development solutions. The client will get the high efficiency, high standard technical support and dedicated and fast professional services from Benia material selection, mould design, trial production, even all stages of official product production.

1. Strong cooperators: Benia have maintained long-term close cooperation with many international famous chemical companies for many years such as SABIC, SOLVAY, BASF,VICTREX, DAIKIN, DUPONT, , HANWHA, etc.

2. Stable supply chain: Benia has a comprehensive production supply chain, and is able to steadily and continuously supply all products and provide services with comprehensive solutions and production applications.

3. Logistics: Benia have long-term and stable cooperative logistics companies that can safely reach around the world while ensuring product quality. We also accept customers to provide their own logistics providers.

4. Small order accepted: Low MOQ accepted. 5KG are available for certain products.

5. Technical support: Benia can customize the marterials according to the customer needs of the product color matching and function.

Q1: What is your shipping method?

A1: DHL/UPS/TNT/Fedex and other air shipments and sea shipments are

all workable.

We could do any shipment you wanted which depends on your purchase

quantity.

Q2:How long does the delievery time take?

A2:In General, the delivery date will be 5-7 working days for

normal quantity. Please leave us a message further if a large

order.

Q3:Do you have any discount?

A3:We can provide a lower price depending on the amount of products

you purchase.

Q4:How about product quality for each batch?

A4:We have the corresponding COA for each product to guarantee the

original factory production.

Q5:When can I get the quote price?

A5:After received your request, we will response ASAP (usually with

in 12 hours)