Shanghai kangquan Valve Co. Ltd. |

|

1 Inch Pneumatic Quick Release Valve , Vent O Mat Air Pressure

Release Valve

Air Release Vacuum Breaker Valve Introduction

FLAT FACE FLANGE AS PER ASME B16.5

BODY:A105 FORGING/A216 WCB CASTING^TRIM # 5 (FULL HARD FACED) AS

PER API 600/602^OTHER

SEPCS: ANGLE BODY, DISC TYPE, BOLTED BONNET, GRAPHITE STEM PACKING

PRESSURE RATING 125 LBS

Air Release Vacuum Breaker Valve Specifications:

| Part Material | |||||||

| NO. | PART NAME | Material | |||||

| 1 | Body & Bonnet | Ductile Iron | |||||

| 2 | Baffle | Ductile Iron | |||||

| 3 | Float Ball | Stainless Steel 304 | |||||

| 4 | Seal Ring | EPDM | |||||

| 5 | Air Release Valve | Assembly | |||||

| Technical Specification | ||||

| Nominal Pressure: 1.0,1.6MPa | ||||

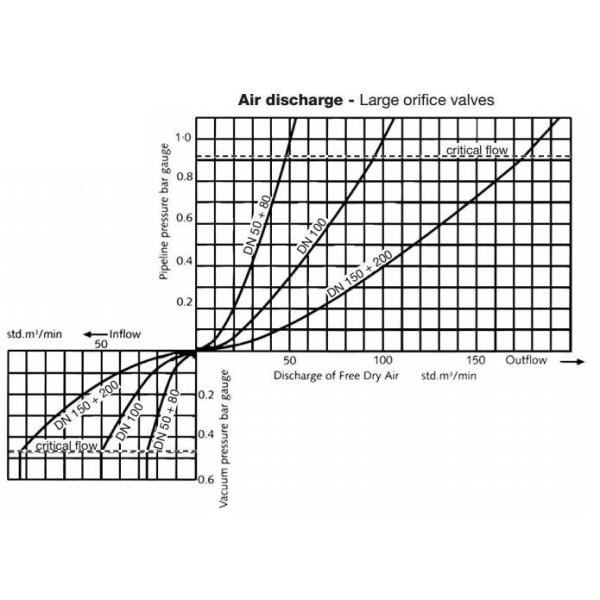

| DN: 50~200mm | ||||

| Medium: Water | ||||

| Work temperature: ≤120℃ | ||||

| Design Standard : BS5163 | ||||

| Flange Standard : BS EN 1092 | ||||

| OTHER STANDARD ARE AVAILABLE UPON REQUEST. |

Standard ; DIN BS ANSI

Working Pressure : PN10 PN16 PN25

Material

: Cast Iron and Ductile Iron

1 ) Size: 1-1/2" to 12"

2 ) Class: PN10, PN16.125LB, 150LB

3

) Type: NBR Floating Ball, Stainless steel /

Brass Spindle

4

) Material: CAST IRON, DUCTILE IRON

All our products are designed and manufactured strictly in conformity with the standard of API, ANSI,

AWWA, JIS, BS and DIN, etc. Most of our manufacturers have obtained ISO 9001, API 6D, TUV and

CE certificates to ensure the quality stability of the products. We provide EN10204 3.1B. Mill Test

Certificate for all our supplied products.

Air Release Vacuum Breaker Valve Description:

The air release valves will be installed at sections of the pipeline |

|

flanged base for connection to a valve stem that connects the air valve to the main pipeline. |

The bore

leading to the flange base shall be in accordance to the size of the main pipeline and the |

|

Competitive Advantage:

DESIGN STANDARDS

•

Coating Powder Epoxy Min. 250 micron

• Three Way Functioning:

-

Release of large volumes of air during pipeline fill.

-

Allows in flows of large volumes of air when pipe is emptied.

- Release of air under pressure

• Low Maintenance

•

Working pressure Min. 0.1 bar Max. 16 bar

•

Hydraulic test performed under 1.5xPN pressure

Install:

REMARKS & APPLICATIONS

•

For water (Not sewage) and neutral liquids.

•

Nominal Pressure: PN 16/25 & PN 25/40

• Working Temperature: -10˚C to 120˚C