Shanghai kangquan Valve Co. Ltd. |

|

Ductile Iron Flange End Swing Check Valve , Brass Metal Seat wafer check valve

1 . Nominal diameter: DN40–DN400

2 . Working pressure: PN10/16

3 . Valve Design: BS5153,API594

4 . Face-to-face: DIN 3202 F6,ASME B16.10

5 . Flange Standard: EN1092-2 PN10/PN16

6 . Test Standard: EN12266,API598

| Nominal Diameter DN | 40-400 | 40-400 | MM | |

| Nominal Pressure PN | 1.0 | 1.6 | Mpa | |

| Test Pressure | Shell | 1.5 | 2.4 | |

| Sealing | 1.1 | 1.76 | ||

| Working Temperature | -10~150 | ℃ | ||

| Suitable Medium | Water,Sewage,Sea Water,Air,Foodstuff,Oil etc. | |||

Application

1. Water works and water resource project

2.Environment protection

3.public facilities

4.Power and Public utilities

5.Building industry

6.Petroleum, chemical

7.Steel, metallurgy

8.Paper making industry

Specifications:

Standards

Design and manufacture as BS1868, ANSI B16.34

Face to face dimensions as ANSI B16.10

End flange dimension as ANSI B16.5

Pressure-temperature ratings as ANSI B16.34

Pressure test as API 598

Applicable Medium: water ,gas,oil,and other causticity medium.

Our service

Competitive Prices:We are the manufacturing company which not only has our own manufacturing workshop, but the casting company as well. So we can provide the straight factory price and service to our customer.

OEM Accepted: We can make the products with the client's demand standard, and also have many experience on OEM.

Good Quality: We have strict quality control system and amounts of testing equipments for different kind of valve, such as size, pressure, working environment etc.

100% QC inspection Before Shipment.

Quick Delivery: We have the large stock for some hot products

Test Pressure

Test Item | Shell Test | Seal Test | Back Seal Test | Air Seal Test | |||||

Medium | Water | Air | |||||||

Unit | MPa | lbf/in2 | MPa | lbf/in2 | MPa | lbf/in2 | MPa | lbf/in2 | |

Pressure (Class) | 150 | 3.1 | 450 | 2.2 | 315 | 2.2 | 315 | 0.5-0.7 | 60-100 |

300 | 7.8 | 1125 | 5.6 | 815 | 5.6 | 815 | |||

400 | 10.3 | 1500 | 7.6 | 1100 | 7.6 | 1100 | |||

600 | 15.3 | 2225 | 11.2 | 1630 | 11.2 | 1630 | |||

900 | 23.1 | 3350 | 16.8 | 2440 | 16.8 | 2440 | |||

1500 | 38.4 | 5575 | 28.1 | 4080 | 28.1 | 4080 | |||

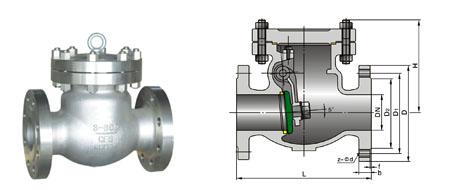

Brief introduction:

The check valve is designed and manufactured according well to API 6D and ANSI B 16.34. It can

work in high temperature and pressure circumstance. It also have the features of good appearance,

nice function and superior. Widely used for petroleum, chemistry, water treatment industries.

Features:

- Resist friction

Valve disc is given enough intensity and rigidity. Disc sealing surface may be built up welded with

satellite alloy inlaid or other material responding to the users’ request.

- Agility of switch

Solid ping is precisely installed and provided with high intensity to ensure operational performance

and service life of valve.

- Sealing credibility

The check valve adopt swing configuration. All the sealing part inside the valve, so all exterior leak

may except the middle flange, and also the middle flange gasket may be different

according to pressure class.

- Distortion compensating

The disc and the hinge are connected between slippery spherical surface, and this makes the disc

can circumgyrate in a little angle and regulates the sealing capability.

Mail part & material

| Item Name of parts | material |

1 | Body | WCB,CF8 |

2 | Seat | 304,A105+ satellite |

3 | Disc | 304,A105+ satellite |

4 | Gasket | Graphite+304 |

5 | Bonnet | WCB,CF8 |

6 | Yoke | WCB,CF8 |

7 | Hinge | WCB,CF8,2Cr13 |

8 | Hinge pin | 2Cr13,304 |

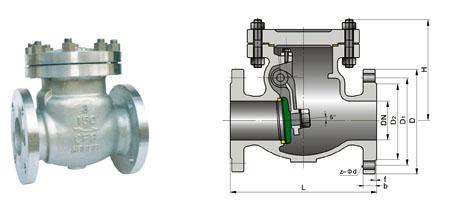

Main Connection Dimensions

Type | Size(mm) | Dimension(mm) | |||||||

inch | DN | L | D | D1 | D2 | b | z-Φd | H | |

H44H/W/Y-150Lb | 1″ | 25 | 127 | 108 | 79.5 | 51 | 12 | 4-Φ15 | 90 |

11/2″ | 40 | 165 | 127 | 98.5 | 73 | 15 | 4-Φ15 | 115 | |

2″ | 50 | 203 | 152 | 120.7 | 92 | 16 | 4-Φ19 | 150 | |

21/2″ | 65 | 216 | 177.8 | 139.7 | 104.7 | 18 | 4-Φ19 | 160 | |

3″ | 80 | 241 | 190.5 | 152.4 | 127 | 19 | 4-Φ19 | 180 | |

4″ | 100 | 292 | 229 | 190.5 | 157 | 24 | 8-Φ19 | 220 | |

5″ | 125 | 330 | 254 | 216 | 185.7 | 26 | 8-Φ22 | 280 | |

6″ | 150 | 356 | 279 | 241.3 | 216 | 26 | 8-Φ22 | 340 | |

8″ | 200 | 495 | 343 | 298.5 | 270 | 29 | 8-Φ22 | 400 | |

10″ | 250 | 622 | 406 | 362 | 324 | 31 | 12-Φ25 | 460 | |

12″ | 300 | 698 | 483 | 432 | 381 | 32 | 12-Φ25 | 530 | |

14″ | 350 | 787 | 533 | 476.3 | 413 | 35 | 12-Φ29 | 580 | |

16″ | 400 | 864 | 597 | 540 | 470 | 37 | 16-Φ29 | 600 | |

18″ | 450 | 978 | 635 | 578 | 533.4 | 40 | 16-Φ32 | 650 | |

20″ | 500 | 978 | 698 5 | 635 | 584 | 43 | 20-Φ32 | 700 | |

24″ | 600 | 1295 | 813 | 749.3 | 692 | 48 | 20-Φ35 | 780 | |

28″ | 700 | 1448 | 927 | 863.6 | 800 | 72 | 28-Φ35 | 850 | |

30″ | 800 | 1524 | 984 | 914.4 | 857 | 75 | 28-Φ35 | 920 | |

Type | Size(mm) | Dimension(mm) | |||||||

| inch | DN | L | D | D1 | D2 | b | z-Φd | H |

H44H/W/Y-300Lb | 2″ | 50 | 267 | 165 | 127 | 92 | 23 | 8-Φ19 | 170 |

| 21/2″ | 65 | 292 | 190.5 | 149.4 | 104.7 | 26 | 8-Φ22 | 180 |

| 3″ | 80 | 318 | 210 | 168.2 | 127 | 29 | 8-Φ22 | 210 |

| 4″ | 100 | 356 | 254 | 200.2 | 157 | 32 | 8-Φ22 | 290 |

| 5″ | 125 | 400 | 279 | 235 | 185.7 | 35 | 8-Φ22 | 290 |

| 6″ | 150 | 444 | 318 | 270 | 216 | 37 | 12-Φ22 | 350 |

| 8″ | 200 | 533 | 381 | 330 | 270 | 42 | 12-Φ25 | 430 |

| 10″ | 250 | 622 | 445 | 387.5 | 324 | 48 | 16-Φ29 | 480 |

| 12″ | 300 | 711 | 521 | 451 | 381 | 51 | 16-Φ32 | 550 |

| 14″ | 350 | 838 | 584 | 514.5 | 413 | 54 | 20-Φ32 | 620 |

| 16″ | 400 | 864 | 648 | 571.5 | 470 | 58 | 20-Φ35 | 650 |

| 18″ | 450 | 978 | 711 | 628.7 | 533.4 | 61 | 24-Φ35 | 690 |

| 20″ | 500 | 1016 | 775 | 685.8 | 584 | 64 | 24-Φ35 | 740 |

| 24″ | 600 | 1346 | 914.4 | 812.8 | 692 | 70 | 24-Φ41 | 800 |

| 28″ | 700 | 1499 | 1035 | 939.8 | 800 | 86 | 28-Φ45 | 860 |

| 30″ | 800 | 1594 | 1092 | 997 | 857 | 92 | 28-Φ48 | 980 |

Type | Size(mm) | Dimension(mm) | |||||||

| inch | DN | L | D | D1 | D2 | b | z-Φd | H |

H44H/W/Y-600Lb | 2″ | 50 | 292 | 165 | 127 | 92 | 26 | 8-Φ19 | 190 |

| 21/2″ | 65 | 330 | 190.5 | 149.4 | 104.7 | 29 | 8-Φ22 | 210 |

| 3″ | 80 | 356 | 210 | 168.2 | 127 | 32 | 8-Φ22 | 230 |

| 4″ | 100 | 432 | 273 | 216 | 157 | 38 | 8-Φ25 | 300 |

| 5″ | 125 | 508 | 330 | 266.7 | 185.7 | 45 | 8-Φ29 | 310 |

| 6″ | 150 | 559 | 356 | 292 | 216 | 48 | 12-Φ29 | 370 |

| 8″ | 200 | 660 | 419 | 349 | 270 | 56 | 12-Φ32 | 450 |

| 10″ | 250 | 787 | 508 | 432 | 324 | 64 | 16-Φ35 | 500 |

| 12″ | 300 | 838 | 559 | 489 | 381 | 67 | 20-Φ35 | 570 |

| 14″ | 350 | 889 | 603 | 527 | 413 | 70 | 20-Φ38 | 640 |

| 16″ | 400 | 991 | 686 | 603 | 470 | 77 | 20-Φ41 | 670 |

| 18″ | 450 | 1092 | 743 | 654 | 533.4 | 83 | 20-Φ44 | 710 |

| 20″ | 500 | 1194 | 855 | 724 | 584 | 89 | 24-Φ44 | 760 |

| 24″ | 600 | 1397 | 1040 | 838 | 692 | 102 | 24-Φ52 | 830 |

Type | Size(mm) | Dimension(mm) | |||||||

| inch | DN | L | D | D1 | D2 | b | z-Φd | H |

H44H/W/Y-900Lb | 2″ | 50 | 368 | 216 | 165.1 | 92 | 38.5 | 8-Φ26 | 220 |

| 21/2″ | 65 | 419 | 244 | 190.5 | 104.7 | 41.5 | 8-Φ29 | 250 |

| 3″ | 80 | 381 | 241 | 190.5 | 127 | 38.5 | 8-Φ26 | 270 |

| 4″ | 100 | 457 | 292 | 234.9 | 157 | 44.5 | 8-Φ32 | 330 |

| 5″ | 125 | 559 | 349 | 279.4 | 185.7 | 51 | 8-Φ35 | 350 |

| 6″ | 150 | 610 | 381 | 317.5 | 216 | 56 | 12-Φ32 | 420 |

| 8″ | 200 | 737 | 470 | 393.7 | 270 | 63.5 | 12-Φ39 | 490 |

| 10″ | 250 | 838 | 545 | 469.9 | 324 | 70 | 16-Φ39 | 550 |

| 12″ | 300 | 965 | 610 | 533.4 | 381 | 79.5 | 20-Φ39 | 630 |

| 14″ | 350 | 1029 | 640 | 558.8 | 413 | 86 | 20-Φ42 | 680 |

| 16″ | 400 | 1130 | 705 | 615.9 | 470 | 89 | 20-Φ45 | 720 |

| 18″ | 450 | 1219 | 785 | 685.8 | 533.4 | 102 | 20-Φ51 | 750 |

| 20″ | 500 | 1321 | 855 | 749.3 | 584 | 108 | 20-Φ54 | 800 |

| 24″ | 600 | 1549 | 1040 | 901.7 | 692 | 140 | 20-Φ67 | 880 |

H44H/W/Y-1500Lb | 2″ | 50 | 368 | 216 | 165.1 | 92 | 38.5 | 8-Φ26 | 222 |

| 21/2″ | 65 | 419 | 244 | 190.5 | 104.7 | 41.5 | 8-Φ29 | 260 |

| 3″ | 80 | 470 | 267 | 203.2 | 127 | 48 | 8-Φ32 | 270 |

| 4″ | 100 | 546 | 311 | 241.3 | 157 | 54 | 8-Φ35 | 330 |

| 5″ | 125 | 673 | 375 | 292.1 | 185.7 | 73.5 | 8-Φ42 | 370 |

| 6″ | 150 | 705 | 394 | 317.5 | 216 | 83 | 12-Φ39 | 440 |

| 8″ | 200 | 832 | 483 | 393.7 | 270 | 92 | 12-Φ45 | 510 |

| 10″ | 250 | 991 | 584 | 482.6 | 324 | 108 | 12-Φ51 | 570 |