Yixing City Kam Tai Refractories Co.,ltd |

|

Verified Suppliers

|

|

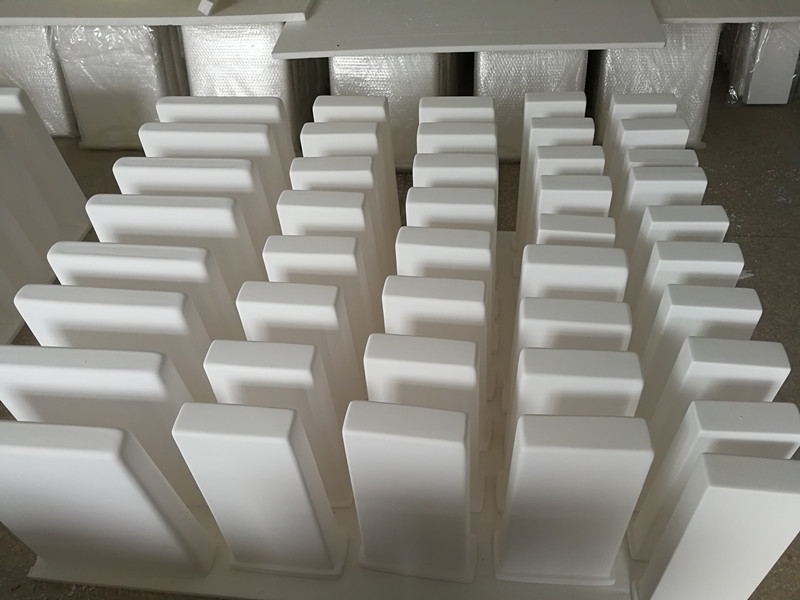

Alumina Ceramic diaphragm in the electroplating industry 500 * 400 * 80mm

1. Description

AluminaCeramic diaphragm electrolysis in the electroplating

industry are mainly used in the following two aspects:Using the

principle of electrolytic reductionoxidation reduction of thick

liquid trivalent chromium. ABS plastic plating pretreatment of

coarse liquid, roughing plating quality directly affects the

quality of plastic parts. In rough of process in the rough of

liquid in the of six price chrome acid and products produced

corrosion reaction generated three price chrome and organic, in

rough of process in the, six price chrome will into three price

chrome, and with three price chrome of content increased, will led

to rough of liquid oxidation capacity weakened, and ABS generated

hydrophilic polar group of speed will sharply declined, led to

rough of effect declined, due to rough of bad, plastic artifacts

and plating layer of combines force also will obviously declined.

Trivalent chromium if the concentration rises above 30 grams per

liter, will seriously affect the up scaling quality resulted in

coarse liquid scrap. Roughing solution waste contains large amounts

of chromic anhydride and sulfuric acid, it will be discarded, not

only wastes a lot of resources, but will seriously pollute the

environment. Abroad (particularly in the automobile industry) using

ceramic membrane electrolysis process reduces the trivalent

chromium, regeneration of the roughing solution in order to achieve

energy conservation and environmental protection.

Used in decorative chromium and hard chromiumplating to lift

impurities. In the production of decorative chromium and hard

chromium, due to workpiece cleaning dirtyreasons, making bath

cationic impurities in gradually increasing, impurities will result

in too much chrome plating color andperformance degradation even

scrapped the plating, electrolytic treatment of plating liquid and

power consumption for a longtime. Ceramic diaphragm electrolytic

plating solutions can effectively remove impurities in the

electrolyte captions, thus improving plating quality of products,

extending the life of plating.

2.Specification of Alumina Ceramic diaphragm

| Water absorbtion | >40 |

| Grain size | 0.5-2 μm |

| Breaking strength | > 20Mpa |

| Acid fastness | >99% |

| Fastness to alkali | >94% |

| Size | 400*500*80mm |

| 160*60*530mm | |

| φ210*800mm,φ210*650mm,φ210*560mm |

Using area of Alumina ceramic diaphragm

Electrolytic ceramic diaphragm is mainly used in the following two aspects in the electroplating industry.

1.Reducing Trivalent Chromium in Coarse Solution by Electrolytic Redox principle.

2.Used in decorative chromium and hard chromiumplating to remove impurities