WEIFANG BETTER CERAMICS CO.,LTD |

|

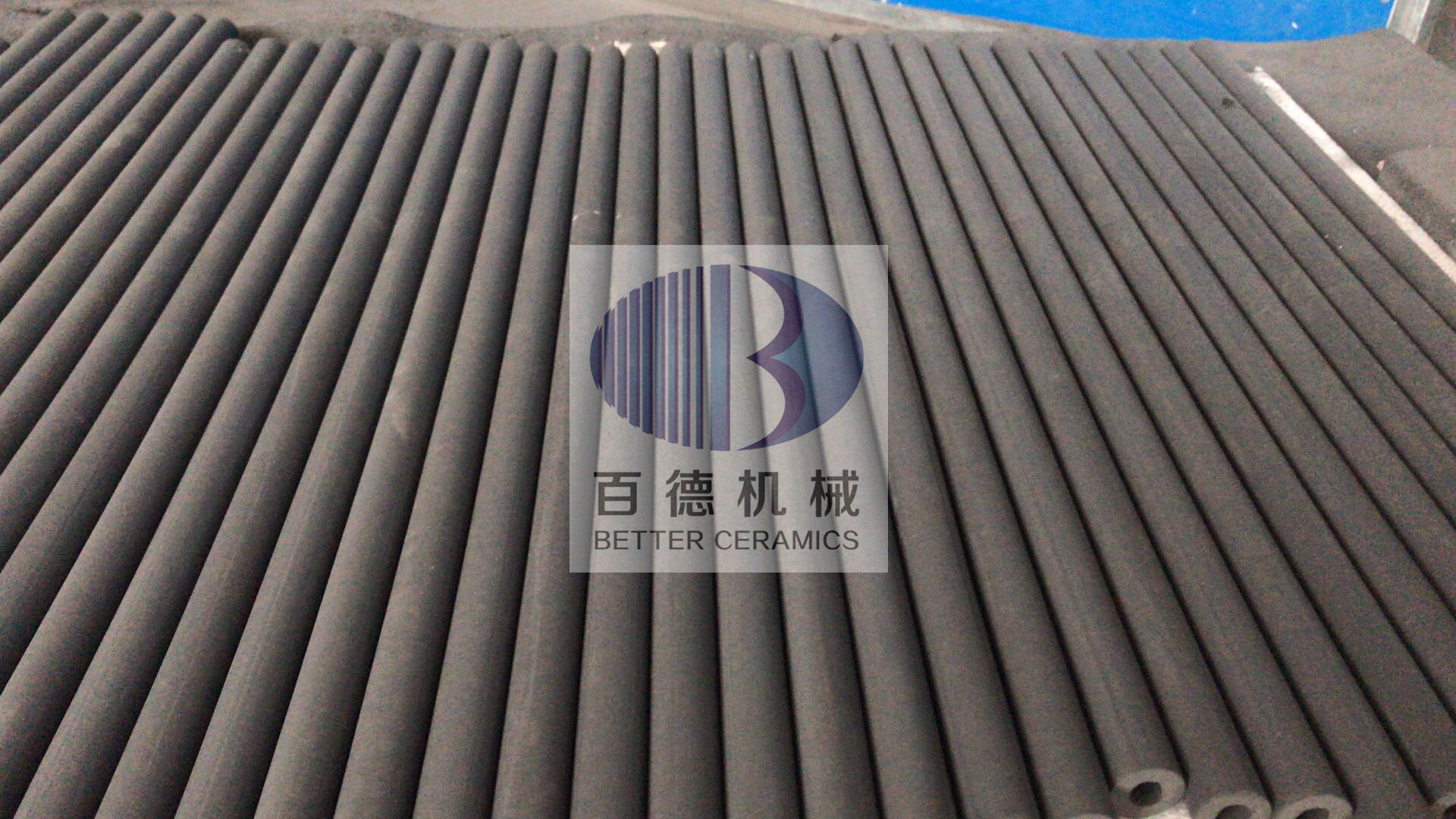

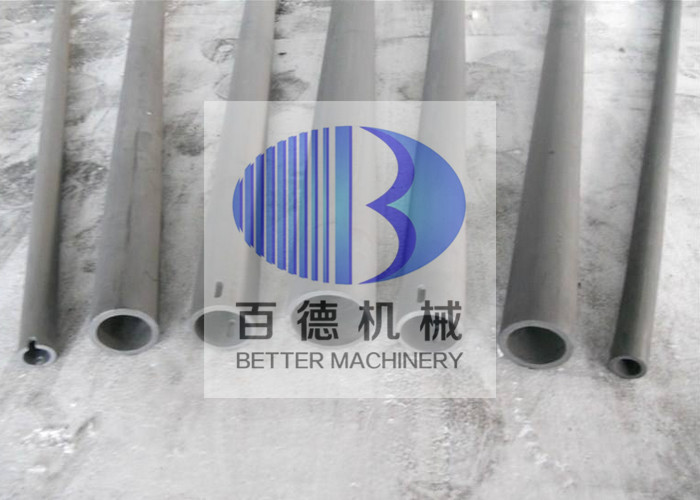

Siliconized Silicon Carbide SiSiC rollers applied to the bearing

frame of tunnel furnace

Siliconized Silicon Carbide SiSiC rollers applied to the bearing

frame of tunnel furnace

Application

It can be used as a bearing ball, roller, ball seat, tooling, new ceramic cutting tools, piston pump, sealing material in the machinery industry;

It can be used to produce three times air valve plate and preheater inner tube in the cement industry,

It can be used as wear and corrosion resistant components, such as ball valve, pump body, combustion carburetor and filter in the chemical industry.

It can be made for metal material processing of mould and die making, such as extubation, mandrel, extrusion, dial wire mould, roll, conveying roller, heating body fixture, thermal couple casing pipe, metal heat processing support, crucible, liquid aluminum tube, aluminum coated line r in metallurgical industry.

It can be used for armored vehicles, aircraft belly, bullet proof clothing, rocket exhaust nozzle and other high temperature work in aerospace industry

Product Introduction

Performance requirements of ceramic sisic ceramic rollers in roller kiln:

Because the sintering temperature is above 1250℃ in roller kiln,so it needs kiln furnitures to support and transport the ceramic products under high temperature,silicon carbide ceramic sisic ceramic rollers is the kiln furniture that support and transport the ceramic products under high temperature,help to complete the entire firing process.So sisic ceramic rollers is the important part for roller kiln,its quality directly affects the normal operation of the kiln and the yield and quality of the ceramic products.

The length of sisic ceramic rollers determines the effective kiln width,roller roundness and straightness will affect the quality of the product sintering and operating rules,thermal shock resistance will affect the service life of silicon carbide roller rod and the factory’s production costs.The high temperature strength of the sisic ceramic rollers is the basis for bearing product weight,while the refractoriness and high temperature load softening point of silicon carbide roller determine the max operation temperature of the roller kiln.