WEIFANG BETTER CERAMICS CO.,LTD |

|

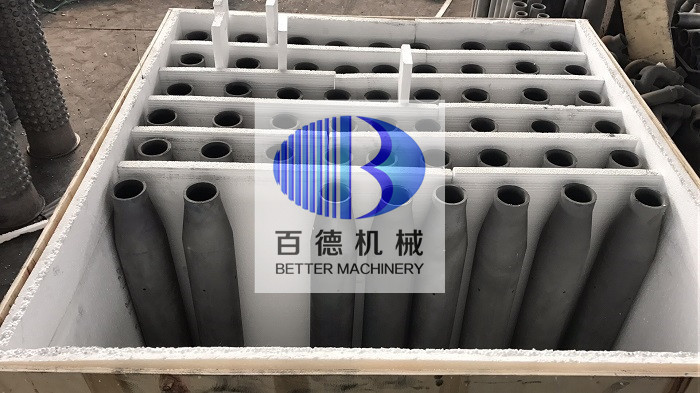

RBSIC(SISIC)Burner Nozzles silicon carbide tube with ware resistance

What can we do for you?

1. Sample is available.

2. ISO manufacture, precise quality standards, modern logistics

management, and sound marketing strategy.

3. Inquiry replied within 24 hours.

4. Patented products.

5. OEM or ODM is available.

6. Some extra accessories can be supplied.

7.The larger quantity you order,the more competitive prices you'll

get.

8. Necessary Certificates can be supplied.

SISIC products are widely used in industrial production

a)Automobile Industry

b)Boiler Industry

c)Chemical Industry

d)Crystallite Glass Industry

e)Magnetic Materials Industry

f)Metallurgy

g)Metallurgy Industry

h)Paper Industry

i)Petroleum Industry

silicon carbide products

• Simple installation, even in existing radiant tube systems

• Flame tubes can be made to any length by combining individual flame tube segments

• Patented flame tube segment design allows flame tube to be bent

• Reduced strain on radiant tubes due to light-weight design

• Long service life due to ceramic material SiSiC which is resistant to high temperatures

The SISIC Burner Nozzles are used for tunnel kiln,shuttle kiln, roller hearth kiln as the flame tubes.The burner nozzles are also used for heating on either direct or indirect furnace systems.

Major Feature:

1.corrosion resistance,high precision surface

2. wear resistance, high strength

3.oxidation resistance,long application life

4. light weight. easy to be made into kinds of forms

5. high temperature tolerance.

| Technical Parameter Of Reaction-Bonded SiC Products | ||

| Item | Unit | Data |

| application temperature | °C | 1380 |

| density | g/cm3 | ≥3.02 |

| open porosity | % | ≤0.1 |

| bending strength | Mpa | 250(20°C) |

| Mpa | 280(1200°C) | |

| modulus of elasticity | GPa | 330(20°C) |

| GPa | 300(1200°C) | |

| thermal conductivity | W/(m·k) | 45(1200°C) |

| coefficient of thermal expansion | K-1×10-4 | 4.5 |

| rigidity | 9 | |

| acid & alkali resistance | excellent | |