Wuxi Wondery Industry Equipment Co., Ltd |

|

Verified Suppliers

|

|

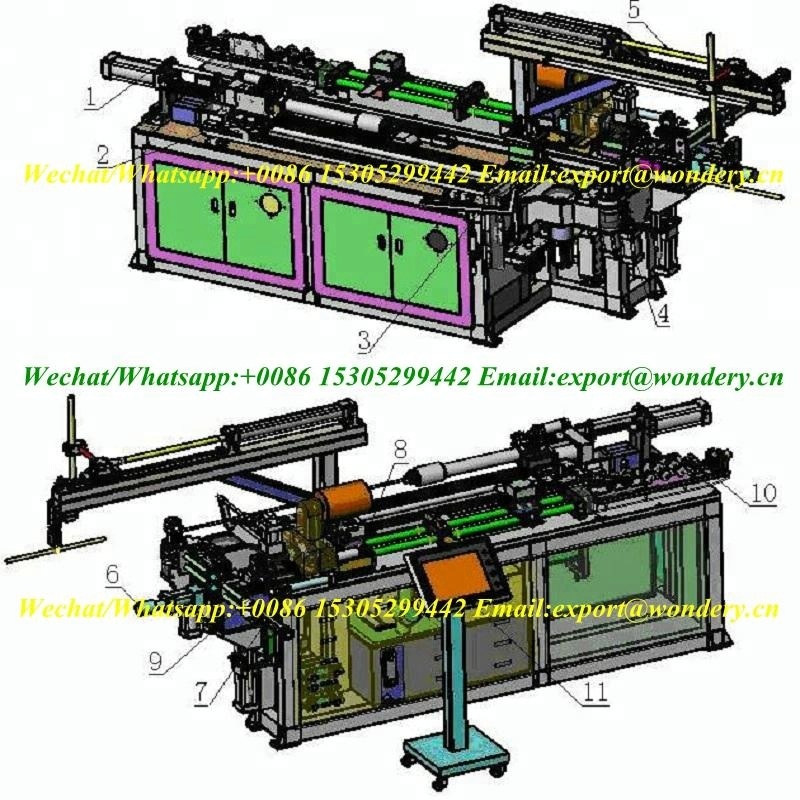

Copper Tube Cutting Forming Bending Machine

1.Description

ated machine is special suited for the copper and aluminium alignment and cutting and end-forming and bending processing. The equipment is including material frame, alignment framework, feeding driving framework, clamping feeding framework, fixed clamping framework, blade head shaft framework, blade retracted framework, clamp and snapping framework, forming position changed framework, end-forming framework, Robot hand clamp drawing framework, Rod retracted framework, dolly rotation shaft framework, double mould framework, bending and clamping framework, empty material with robot hand framework, pneumatic system and hydraulic system.

2.Main specification and technical parameter sheet

No. | Title | Integrated machine |

1 | Cutting journey and accuracy | Cutting circle:200-750mm/one time The accuracy will be ±0.3mm if the cutting length is less than 1000mm; If 1000mm<cutting length<1500mm, The accuracy will be ±0.5mm; Max. feeding peed is 0.75m/s. |

2 | Max.feeding journey | 700mm |

3 | Outer Diameter and the thickness of tube | Φ4.76~φ19.05,Thickness:0.75~1.2 |

4 | Cutting efficiency | ≤6s/per piece(If the tube length is 1000mm) |

5 | How many steps for the end forming | Two step end forming |

6 | Max.Clamping Force | 1000KG |

7 | Max. Pressure Force | 1000KG |

8 |

Forming efficiency | One step forming time≤3S/per piece |

Two steps forming time≤8S/per piece(Including movement and end forming movement time) | ||

9 | Max.bending diameter*thickness | φ19.05mmX1mm Double mould: can bend the two radius in one time,the max. radius is 40mm |

10 | Bending radius | Double mould: can bend the two radius in one time,the max. radius is 40mm |

12 | Workpiece length | 230~1200mm (can to 1600mm if no mandril) |

13 | Feeding speed and journey | 0~1200mm; 0~1000mm/s;Accuracy: ±0.05mm |

14 | Max.feeding speed | 0.75-1m/s( adjustable) |

15 | The total speed for cutting forming and bending | For example,if bending 1000mm, there is five 90°of bending, the diameter is 9.52mm(Including cutting, double forming,bending,discharging), it will be less 16s for one workpiece. |

16 | The final analysis of the product | No obvious scar on the surface and no burr in the cutting position |

17 | power | 3 phase 380V 50Hz(Customer Request) |

18 | Pneumatic pressure | 0.5-0.6MPa |

19 | Colling way | Air |

20 | Total output power | 3.5KW |

21 | Oil pump moter | 2.2KW |

22 | Dimension(mm) | 3500X1600X1500(L*W*H) |

23 | Weight(KG) | 2000 |

The machine is packed in plywood cases which can be moved through forklift by its feet.

The nearest sea port is Shanghai port which is the largest and most convenient port over China.

The delivery time is 60 days after receipt of down payment.

The machine can be loaded into normal container (20GP or 40GP).

Our company provides test-running service to the customers. We would send our engineers to the buyer's site for installation, test-running and training service. The customer should bear the following costs: round-way air ticket fare, and board and lodging, and daily allowance.

The warrantee period is 1 year after completion of test-running.

We provide technical support life-time.

Wuxi Wondery Trading Co., Ltd is a comprehensive equipment supplier cooperating with various domestic factories. We can supply the heat exchanger production line for auto radiators, condensers, oil-coolers, heaters, or other products, and HVAC condensers and evaporators.

Auto Condenser Production Line

Including: collecting pipe single-punch mold; collecting pipe automatic forming machine; aluminum one-end or two-end chamfering machine; semi-automatic core builder; condenser

side plate forming machine; collecting pipe slitting machine; flat tube straightening and cutting machine; aluminum brazing furnace.

Auto Radiator Production Line

Including: machines for brazing type radiator: fin making machine, radiator core assembly machine, plastic tank crimping machine, leak detector, header and side plate mold, and brazing furnace; machines for mechanical type radiators: fin mold, tube-to-fin expansion machine,

tube-to-header expansion machine, plastic tank crimping machine, etc;

Evaporator Production Line

Including: fin mold (single-punch type or progressive type); serpentine tube bending machine; evaporator assembly table, etc;

HVAC Evaporator and Condenser Production Line

Including: heat exchanger bending machine; Long/short U-tube bending machine; copper tube straightening and cutting machine; fin press line; progressive fin mold; vertical/horizontal expansion machine; others.

Other Heat Exchanger Making Machines

Machines and/or molds for similar heat exchanger products and their accessories

1) Q: What is the power supply of the machine?

A: The power supply of the machine is to be decided by the customer's side. We are able to adjust the power supply (volt, and phase) through a transformer so that the machine is ready for use at the end user's site.

2) Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage, planned output, etc.

3) Q: What is the payment term?

A: The payment term is 30% down payment, and 70% before delivery (T/T mode).

4) Q: What is the delivery time?

A: The delivery time of the machine is 60 days after receipt of down payment.

5) Q: What is the warrantee period of the machine?

A: The warrantee period is 1 year after completion of test-running.