Ironstone-Meca Industry |

|

Verified Suppliers

|

|

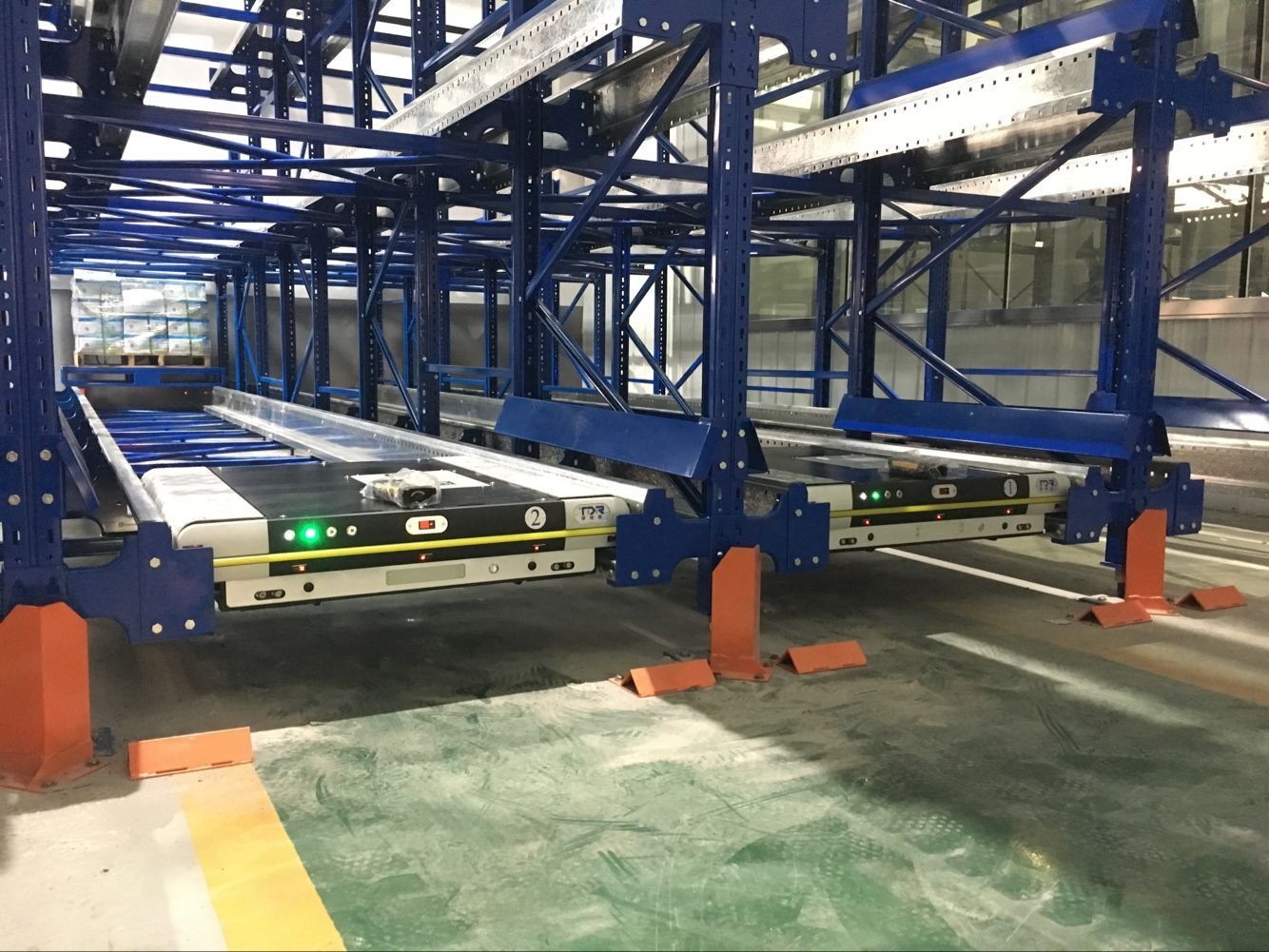

Advanced Automatic Radio Shuttle Pallet Racking System for High-Density Storage

The radio shuttle pallet racking system is a semi-automatic storage system. It is equipped with shuttle trucks that can be controlled by an operator with a controller. The forklift is in charge of loading and unloading pallet cargoes on the shuttle. And the shuttle is able to transport pallets to any position in each lane. The storage density and efficiency are high in the system and it is favorable for storing large volumes of products with high throughput.

Radio shuttle pallet racking is a semi-automated solution for storing large capacity palletized goods and large quantities of stored products. They are often used in warehouses and distribution centers for food and beverages, or warehouses with special storage conditions. Radio shuttles are particularly effective for distribution or logistics centres, where you may need fast and efficient supply and distribution.

At the same time, this type of pallet storage and retrieval system allows for maximum optimization of storage capacity as it reduces the need for aisles between racks. With this system, you can store different numbers of pallets in depth depending on specific needs or seasonal loads. At the same time, each pallet can be accessed quickly.

| Name | Pallet racking | Material | High Strength Steel |

| Beam levels | 2~15 tiers per bay rack | Color | (RAL Code) Green, Orange, Blue, Yellow, Etc. |

| Upright Frame Height | 2500mm~15000mm | Weight Capacity | 500~3000kg per level |

| Beam Width | 1000mm~3900mm | Frame Depth | 700mm~1500mm |

| Finish | Epoxy Powder Coated for corrosion prevention | ||

| Usage | Cargos Storage | ||

| Package | Plastic stretch film, corrugated paper, Cartons, wooden bars, crates, and metal strips, etc. | ||

| Accessories | Bolts and nuts, Upright protectors, decks, etc. | ||

| Certification | RMI/AS4084-2012 /CE/ ISO9001 | ||

| Delivery time | 7~25 days as per order quantity | ||

| Assemble & installation | Detailed assembly instructions are available as well as dispatching installation engineer for project installing at site. | ||

Instruction about Radio Shuttle Controlled Platform

The radio shuttle rack system uses a radio-controlled platform that moves automatically along the rack itself. The special design and engineering allow the platform to move smoothly, whether it is storing or retrieving pallets at this time.

The material handling machines do not need to enter the aisles of the radio shuttle storage system in order to place or retrieve pallets. This significantly reduces the distance they have to travel, reduces the need for new lifting equipment, reduces maintenance costs, and reduces costs for operators and drivers.

There is less damage to the steel structure of the warehouse racking as the hoist does not need to access the racking system to place or remove pallets. Each radio shuttle platform relies on a very durable lithium battery with long autonomy, enough for over 16 hours of continuous operation. It is also extremely fast to recharge, taking less than 3 hours to complete.

The forklift truck driver can easily control all storage and retrieval movements of the automatic shuttle platform via remote control. The absence of forklift trucks in the warehouse tunnel and the construction of the system means that the risk of accidents is significantly reduced. At the same time, storage capacity is significantly increased.

Characteristics of Radio Shuttle Pallet Racking System