Anping MamBa Screen Mesh MFG.,Co.Ltd |

|

Verified Suppliers

|

|

Anping Mam Ba Wire Mesh MFG Company, which is founded in 1989, has been devoted into wire cloth and screen media production for 26 years. The company owns 18 patented products, all of them have been up to EU, GB and ASTM standards. The company has acquired certificates of ISO 14001 Environmental Management System, ISO 9001 Quality Management System and OHSAS 18001 Occupation Health Safety Management System.

Mam Ba self-cleaning screen mesh

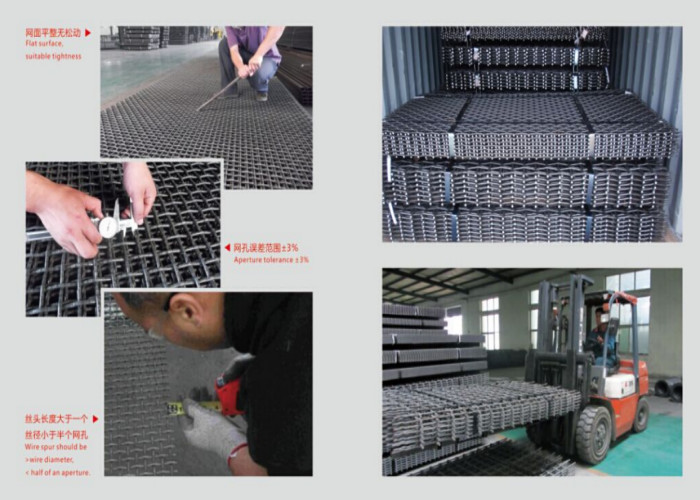

The Anti-blocking Screen is a method of weaving the wire mesh. The overlap points of warp are not prominent, and the surface is flat.

Anti-blocking Screen is easy to leak, wear-resistant and corrosion-resistant.

The screens are made of spring steel or stainless steel wires kept at the right distance by crimped steel wire .

Wire-ripple screens are mainly used at plant processing material at high temperature,like asphalt plant.

Material:high carbon spring wire, stainless steel wire

It can only be fixed with polyurethane stripe

Features: don’t require screening accuracy, as long as the large production, it is recommended to use this screen.

Advantages of the Anti-blocking Screen :

There are three types according to weaving way:

A B C

C TYPE: same self cleaning action reinforced for heavier loads and bed depth.

Some specifications of A type are reference. Special sizes can be at customized.

| Aperture mm | Wire dia mm | Opening area % |

| 1.5 | 1.2-1.6 | 38-31 |

| 1.75 | 1.2-1.25 | 40 |

| 2 | 1.2-1.6 | 43-37 |

| 2.5 | 1.2-2 | 48-35 |

| 3 | 1.2-2 | 52-40 |

| 3.5 | 1.2-2 | 56-42 |

| 4 | 1.2-2 | 58-45 |

| 4.5 | 1.2-2.5 | 62-40 |

| 5 | 1.2-2.8 | 65-41 |

| 5.5 | 1.5-2.5 | 61-48 |

| 6 | 1.5-2.8 | 64-48 |

| 6.5 | 1.5-3.15 | 66-47 |

| 7 | 2-3.15 | 61-49 |

| 7.5 | 2-3.15 | 62-52 |

| 8 | 2-3.15 | 63-53 |

| 8.5 | 2.5 | 61 |

| 9 | 2-3.15 | 67-56 |

| 9.5 | 2.5-3.15 | 63-57 |

| 10 | 2-3.15 | 69-59 |

| 10.5 | 2.5-3.15 | 66-60 |

| 11 | 2-3.15 | 72-61 |

| 11.5 | 2.5-2.8 | 66-64 |

| 12 | 2-4 | 73-57 |

| 12.5 | 2.5-4 | 69-58 |

| 13 | 2-4 | 75-59 |

| 13.5 | 2.8 | 68 |

| 14 | 2-4 | 76-61 |

| 14.5 | 2.5-4 | 73-62 |

| 15 | 2.5-4 | 74-63 |

| 15.5 | 3-3.15 | 70-69 |

| 16 | 3-4 | 71-64 |

| 17 | 2.5-4 | 76-66 |

| 18 | 3-4 | 73-67 |

| 19 | 3-5 | 76-68 |

| 20 | 3-5 | 79-69 |

| 21 | 3-5 | 75-71 |

| 22 | 3-5 | 80-72 |

| 23 | 4 | 73 |

| 24 | 4-6 | 74-69 |

| 25 | 4-6 | 74-70 |

| 26 | 4-6 | 75-71 |

| 27 | 4-8 | 76-70 |

| 28 | 3-8 | 82-69 |

| 29 | 4-9 | 77-70 |

| 30 | 4-9 | 82-70 |

| 32 | 4-9 | 79-70 |

| 35 | 4-9 | 81-74 |

| 40 | 4-9 | 83-75 |

| 44 | 4-9 | 84-76 |

Self-cleaning screens are available in a side-tensioned or end-tensioned configuration.