Gaoge-Tech Instrument Co., Ltd. |

|

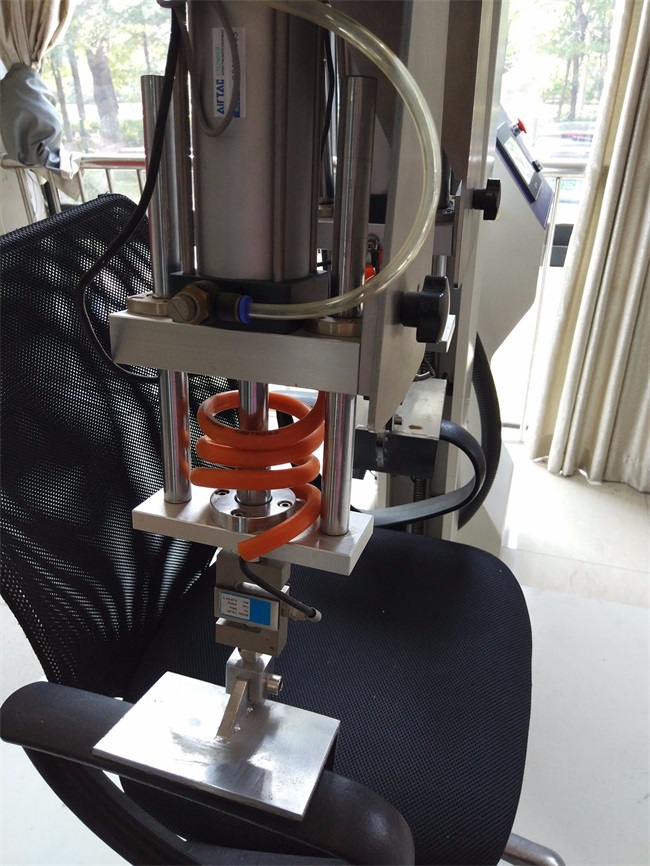

Automatic EN1335 BIFMA X5.2 Office Chair Swivel Durability Testing Machine With LCD Touch Screen

Description

Swivel Durability Tester is used for seating furniture, with load pad and accessories for the fixing of the chair, according to DIN 4551, EN 1335, NEN 1812 and BIFMA 5.1.

It is used for office chairs, stools, gas springs, tested units are subjected either to the entire test procedure

prescribed by the standards or to selected individual tests.

The test axes each have their own controllers assembled in the immediate vicinity, which are operated from

a Touch panel and controlled by PLC.

Consisting of

1 test frame

1 swivel test rig, driven electrically

1 actuator load controlled, piston diameter 80mm, piston stroke

500mm, 2500N

1 load pad, diameter 200mm in acc. to DIN EN 1335 with cardanic clamping connection

1 range of standard fixing elements

1 load cell 5kN - 1 set of stops, clamps

Specifications

| Counter | 0-999,999, memory, output control |

| Impact sandbags diameter | 16 inch 125 pounds standard sandbbags |

| Static pressure mould diameter | 8 inch, 165 pounds briquetting |

| Impact speed | 10-30 times/minute or specified |

| Static pressure speed | 10-30 times/minute or specified |

| Cylinder stroke | 0-300mm |

| Rail height | 90-135cm |

| Machine size | 270*85*80cm |

| Power | AC220V, 3A |

| BIFMA requirements | impact 100000 times+ static pressure 20000 times(left) +static pressure 20000times (right) |

Features

Build up by the control system, pneumatic system and adjust the

mechanical part of composition and so on Made by aluminum frame,

beautiful shape Adopt imported brand pneumatic fittings and

cylinder products It can work unattended for a long time

Test method:

1. Seat surface static load test

Choose corresponding test level, will load by loading pad,

successively in the following two position vertically downward Add

10 times each.

-Loading templates determine the seat surface mount point

-Surface center line 100 mm from the front seat along the

disadvantage

-For a specimen with two or three seats, the loading position as

follows

-Two seats of the specimen, and at the same time in the template to

determine two seat surface mount point and front loading point load

each 10 times

-Three seat specimens, at the same time, in any side surface and

the middle face templates determine the loading point and front

loading points each , Load each load force 10 times at least 10 s

Bench test, load by small seat surface mat, the force on the

template to determine the loading point. The end of the test and

check the overall structure, sample and record, evaluation

2. Use block depends on the foot side of the chair or stool.Choose

products corresponding test level, will load mat is perpendicular

to the specified load through the back of the chair direction load

10 times,

Load time, load balance on the surface of the seat should be loaded

into the loading templates determine the seat surface loading

point, balance force size is commonly 750 n (75 kg), such as

tilting the trend, the unbalanced force increase, until just stop

chair tilting, and to remember, record the balance force. Loading

position in the following two positions in a lower position.

- loading the template back mount point is determined

-Longitudinal axis, the back of the chair back down at the top of

the 100 mm

For a specimen with two or three of the chair, according to the

above regulations, loading is as follows

-Two specimens of the back of the chair, at the same time two back

loading

point loading 10 times

-Three specimens of the back of the chair, on either side at the

same time and in the middle of the back of the chair to load 10

times

Each loading force to keep at least 10 s

Static load should be no less than 410 n the back of the chair

Frame for rectangular stool specimen foot, regardless of seat

surface shape, in turn, the force on each side with the rectangular

feet adjacent points corresponding to the front of the seat along

the 5 times ,Frame for triangle stool specimen foot, are in turn

push force along arbitrary direction on both sides of the center 5

times of load.

End of the test, first remove the force in the back of the chair,

then remove the forces acting on the surface of the present. Check

the overall structure, sample and record, Evaluation.

Back of the chair, seat surface joint static load test, static load

test also can be being done alone

3.Seat surface, the durability of the chair joint test

Seat surface 950 N, and then applying force of 330N on the back,

with no more than 40 times/min frequency cycle ring 200000 times,

then examines the specimen damage.

Standard

BIFMA 5.2-2017.8

QB/T2280