Introduction

1. The mainframe is fitted with numeric-control system special for

shearing machines;

2. The position of rear stopper is displayed in a real-time manner;

3. Multi-step programming function is available and the rear

stopper is able for automatic operation and continuous positioning,

to achieve an automatic adjustment for position of rear stopper;

4. It is provided with counting function for shearing, to display

the shearing numbers in a real-time manner, able for power-failure

memory of position of rear stopper, procedures, and parameters;

5. Imported ball bearing lead screw and linear guide rail are used,

to ensure the positioning precision, so that the processing

precision of machine is higher;

6. Ball screw and line guide rail as optional for guarantee higher

precision;

7. NC controller: China E20, Holland DELEM DAC310; [ Guarantee the

machine precision in 0.15mm]

8. Digital display control: China E10-S.

Parameters:

| Model | Shearing Thickness | Shearing Width | Shearing Angle | Number of Stroke | Backgauge Rang | Motor Power |

| mm | mm | ° | min | mm | kw |

| QC12K-4×2500 | 4 | 2500 | 1°30` | 18 | 20-600 | 4 |

| QC12K-4×3200 | 4 | 3200 | 1°30` | 18 | 20-600 | 5.5 |

| QC12K-4×4000 | 4 | 4000 | 1°30` | 12 | 20-600 | 5.5 |

| QC12K-4×5000 | 4 | 5000 | 1°30` | 10 | 20-600 | 5.5 |

| QC12K-4×6000 | 4 | 6000 | 1°30` | 7 | 20-800 | 7.5 |

| QC12K-6×2500 | 6 | 2500 | 1°30` | 18 | 20-600 | 7.5 |

| QC12K-6×3200 | 6 | 3200 | 1°30` | 14 | 20-600 | 7.5 |

| QC12K-6×4000 | 6 | 4000 | 1°30` | 12 | 20-600 | 7.5 |

| QC12K-6×5000 | 6 | 5000 | 1°30` | 10 | 20-600 | 7.5 |

| QC12K-6×6000 | 6 | 6000 | 1°30` | 7 | 20-800 | 7.5 |

| QC12K-8×2500 | 8 | 2500 | 1°30` | 14 | 20-600 | 7.5 |

| QC12K-8×3200 | 8 | 3200 | 1°30` | 10 | 20-600 | 7.5 |

| QC12K-8×4000 | 8 | 4000 | 1°30` | 8 | 20-600 | 11 |

| QC12K-8×5000 | 8 | 5000 | 1°30` | 7 | 20-800 | 15 |

| QC12K-8×6000 | 8 | 6000 | 1°30` | 6 | 20-800 | 15 |

| QC12K-8×8000 | 8 | 8000 | 1°30` | 5 | 20-800 | 15 |

| QC12K-10×2000 | 10 | 2000 | 1°30` | 12 | 20-600 | 11 |

| QC12K-10×2500 | 10 | 2500 | 1°30` | 10 | 20-600 | 11 |

| QC12K-10×3200 | 10 | 3200 | 1°30` | 10 | 20-600 | 11 |

| QC12K-10×4000 | 10 | 4000 | 1°30` | 8 | 20-600 | 15 |

| QC12K-12×2000 | 12 | 2000 | 2° | 12 | 20-600 | 15 |

| QC12K-12×2500 | 12 | 2500 | 2° | 10 | 20-600 | 15 |

| QC12K-12×3200 | 12 | 3200 | 2° | 9 | 20-600 | 15 |

| QC12K-12×4000 | 12 | 4000 | 2° | 8 | 20-800 | 18.5 |

| QC12K-12×5000 | 12 | 5000 | 2° | 7 | 20-800 | 22 |

| QC12K-12×6000 | 12 | 6000 | 2° | 6 | 20-800 | 22 |

| QC12K-12×8000 | 12 | 8000 | 2° | 5 | 20-800 | 22 |

| QC12K-16×2500 | 16 | 2500 | 2° | 8 | 20-600 | 18.5 |

| QC12K-16×3200 | 16 | 3200 | 2° | 7 | 20-600 | 18.5 |

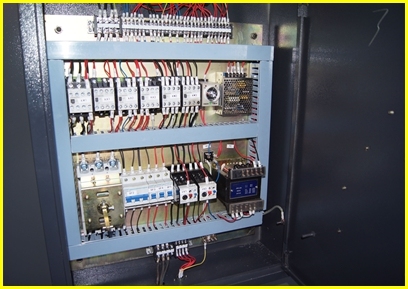

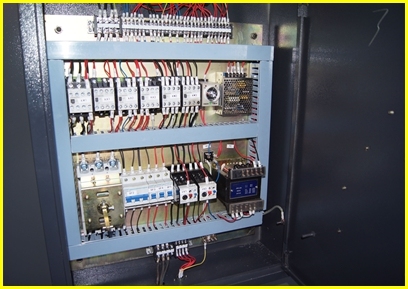

Electric control system

1. The electrical component and material meet the international

standard, safe and long-lived.

2. The machine is with AC380V,50HZ and the control loop is with

AC220V. 24V for Backguage controlling, 6V for indication Light,24V

for other component.(According to customer requirements changes)

3. Electric box on left side. The operated buttons are on the

machine's button table. The electrical switch, indicator lights are

in the electrical case.

Front .Backguage

1. Frontgauge:Setting on table, with indicator, adjust stopper.

2. Backguage:Setting on tooling set, swing with up-tooling set,

driven by 0.55KW Electric Motor. The rear stopper is fitted with

electric adjustment and manual adjustment devices ,and digital

display device is available for display of size of stopper and

times of shearing.

Parts of supply list

Front support arm

Front support arm Electric components SIMENS

Electric components SIMENS Estun E10 System

Estun E10 System | Item | Description | Parameter | Unit |

| 1 | Cutting Length | 3200 | mm |

| 2 | Max Cutting Thickness | 6 | m m |

| 3 | Cutting Angle | 1 ° 30 ′ | degree |

| 4 | No. of Forging Material | 12 | Piece |

| 5 | Speed of Stroke | 5-12 | Hypo/Min |

| 6 | Throat Depth | 150 | m m |

| 7 | Travel Of Backguage | 5 00 | m m |

| 8 | Motor Power | 7.5 | Kw |

Packaging & Shipping

(1)before packing,the machine tool will be testing for 48 hours to

ensure all the equipment is 100% qualitied.

(2)before loading,stable package,professional and skilled loader

reduce damage of product during transport.

(3)after loading,our professional documentary staff will follow the

order till the product departs from port.