QINGDAO SINO-HOLYSON MACHINERY CO., LTD |

|

Verified Suppliers

|

|

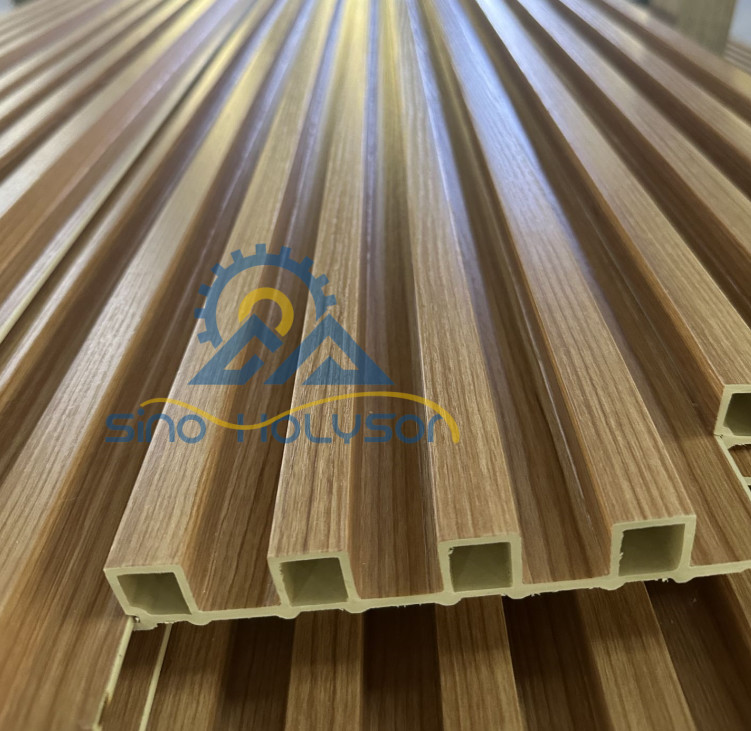

3tons Per Day WPC/PVC Interior Great Wall Production Line For Fluted Wall Panel

WPC/PVC Interior Great Wall Production Line For Fluted Wall Panel

Product Description

PVC WPC profile extrusion line is mainly used to produce PVC window profiles, wide doors, elbowboards, multi-hole threading pipes(4-hole, 6-hole, 7-hole, 9-hole, etc). The line can adopt different twin screw extruders according to different profiles, sections and moulds, and also equip with vacuum forming table, haul-off machine, cutter, stacker or other auxiliary machines.

1. The finished product is mainly made from PVC, PE, PP wooden powder, cotton stalk, rice chaff and other natural fibers.

2. Plastic-wood compounded finished product is a new type of ideal environment-friendly material, which is made from PVC resin, polyolefin plastic and cellulose(straw, cotton stalk, wooden power, rice chaff, etc) with special procession and treatment.

3. It has such advantages as rot prevention, non-deformation, non-shading, pest resistant, fire-proof, split proof, etc.

4. It can be processed by a sawing machine or a planning machine.

5. It not only has natural properties of wood, but also has many colors for you to choose as per your demand.

6. It is widely used in making rail, passages, stairs, outdoor desk and chair, flower frame, pools etc. in addition, it can be used for indoor plate decoration , kitchen cabinet board, tray etc.

Consist of the machine line:

Process Flow

Raw material → mixing → feeder→ double screw extruder → mould → vacuum calibration table → haul-off traction → cutting machine → stacker

Product Parameters

| Extruder Size | Motor Power | Product Width | Production Capacity |

| SJSZ51/105 | 22KW | 250mm | 120-180kg/h |

| SJSZ65/132 | 37KW | 600mm | 150-240kg/h |

| SJSZ80/156 | 75KW | 1200mm | 300-350kg/h |

Main Components

Extruder adopts PVC ceiling dedicated screw, make sure best plastisizing effect.

Extruder speed and haul off speed controlled by ABB frequency converter, saving power and easy adjusting speed.

Extruder temperature adopt PID control, temperature fluctuation self adjusting, it realize the high automatic level.

FAQ