Wuxi Luole Machinery Co., Ltd |

Downpipe / Water Pipe / Downspout Roll Forming Machine , Drain Pipe Production Line

Quick details:

1. Condition: New, Type: Tile Forming Machine

2. Tile Type: Steel, Use: Roof, Place of Origin: Wuxi

3. Brand Name: LUOLE, Certification: ISO9001 and CE

Description

Rain gutter pipe downspout roll forming equipment consisted of decoiler , roll forming machine include the seam lock

roller stations, saw cutting system and automatic stacker or manual

stacker.

● The raw material for rain gutter pipe downspout roll forming

equipment can be Aluminum and stell. The thckness should be around

0.5mm.

● We have many experiences in the down pipe equipment for many

customer in domestic and abroad, we believe it has became one of

our advantage products.

● The structure base of the main roll forming machine is H beam base

with steel plate welded stand which is very reliable and good

performance.

● All the components of machine are from brand-famous enterprise so

that they ensure the machine normal function very effectively.

● We adopt the automatic length-fixed forming and on line cutting

to guarantee the length to be precise and the finished product

clear without deforming.

● The life of the machine can be reach 10 years.

The downspout roll forming machine is designed by ourselves, the

machine produce occlusive round downspout, which is beautiful and

durable with high quality

The Whole Line Components: Manual/Hydraulic Un-coiler, Leveling

Unit,Roll-forming M/C, Cutting Unit, PLC System, Transmission Unit,

etc.

Specifications

| Item | Downspout Roll Forming Machine | |

| 3ton passive decoiler | Structure of pedestal | braking, mandrel holder, slider narrow and expanding |

| Capacity of decoiler | 3ton | |

Main roll forming machine | Fit for raw material | Forming thickness 0.4-0.6mm |

| Roll forming station | about 17stations | |

| Crimping machine | Motor power | 4KW |

Electrical control system | Low voltage | Schneider |

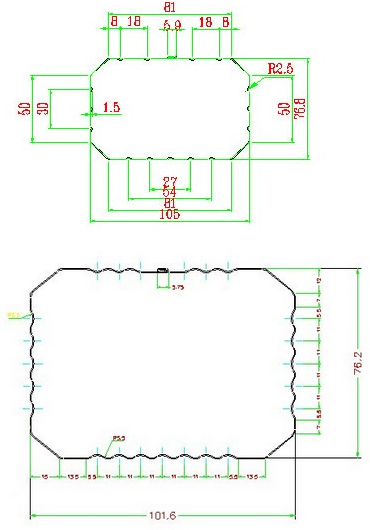

Reference Rainspout Drawing

Application

The roll formed product is more durable than the traditional ppc

pipe, and not easy to aging.

It will make the project more integrate, and help enhancing the

image of all project.

Machine pictures

Advantages

1) Guarantee:

In correct operation and maintenance, the machine is one year

guarantee since leaving the seller’s factory

2) Installation:

If buyer need, the seller will send one or two technician to the

buyer's factory to install & testing the machine, the buyer

will assist the seller’s technician to get the visa and pay for the

two-way flight tickets and local accommodation, visa cost. by the

way , buyer pay 50USD/day for technician extra

3) Spare parts:

We can send you the spare parts for free if they are broken

naturally

4) Main machine:

The diameter of the shaft is 70mm.the main body of the machine is

made of 300mmH-Steel