Wuxi Luole Machinery Co., Ltd |

|

Automatic Highway Guardrails Roll Forming Machine are Essential to Ensure Highway Safety Used in Europe Market

Guardrail Profiles used in Highway:

Highway guardrail, considered as a passive barrier, is widely installed to keep the vehicles running inside of road. When inevitable collision occurred, highway guardrails can effectively decelerate the speed of errant vehicles and redirect them back to the road by controlling the exit angles. Additionally, it also makes the highway apparent to avoid running animals to stray into the roads.

Two/Three Waves Highway Guardrail is a perfect choice for Highway Guardrail. But it could also be the raw material of other road guardrails.

The expressway fence is the main form of a semi-steel fence, which

is a continuous structure that is stitched with a corrugated steel

guardrail and supported by the main pillar.

When the vehicle collides with it, it is not easy to be crashed

because of the good impact resistance and energy absorption of the

corrugated steel guardrail, and it can also protect the vehicle and

the crew.

According to the differences of the corrugations and punched holes, the guardrail roll forming machine are designed with two working methods as demonstrated below.

1. The first one is making the guardrail by punching first and then forming the shape. This is adopted by most of manufacturers.

2. Our machine, unlike common products on the market, forms the shape first and then punches holes. This method ensures the high precision of punching positions, thus satisfying even the most captious customer. Meanwhile, the inclined punching system also contributes to the high punching precision, and this facilitates the connection of guardrails.

Aside from the above, this guardrail roll forming machine is able to manufacture double-wave and triple-wave guardrails, and pressing dies can be applied to produce C&U posts. In addition, our machine could be designed to work with hydraulic decoiler and stacker upon customer's request.

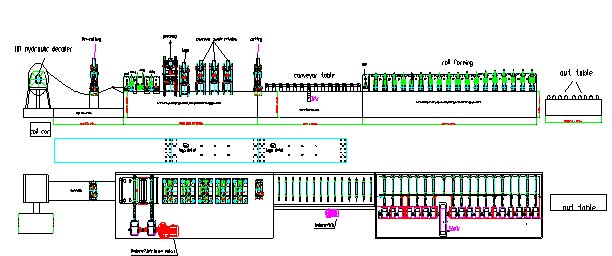

Machine Layout:

De-coiling ---- Feeding ---- Leveling ---- Hole punching----Roll Forming ----Cutting----Manual out table

Specifications:

| Item No | Description | Offered specification |

| 1 | Roll Forming Machine | Guard rail |

| 2 | Material Width | According to the profile |

| 3 | Rolling Speed | 5-12m/min |

| 4 | Rolling Thickness | 2.0-4 mm |

| 5 | Control System | PLC (Panasonic) as list in the note |

| 6 | Un Coiler | 10 ton hydraulic de-coiler |

| 7 | Leveling Station | Upper is 3 rollers, down is 4 rollers (total is 7 stations), material is 40Cr steel, HRC48-52°, 7.5kw |

| 8 | Punching | Holes |

| 9 | Roll Forming | 13 stations or more |

| 10 | Material Of Cutting | Cr12Mov quenching 58-62ºC |

| 11 | Hydraulic Station Power | 30 Kw |

| 12 | Forming Power | 245 Kw |

| 13 | Conveyor table | Manual |

| 14 | Roller Material | GCR15, HRC58-62ºC, coated with chrome |

| 17 | Shaft Material and DIA | ¢100mm, material is 45# forge steel |

| 18 | Maim Motor Power | 55kw |

| 19 | Structure Of The Stations | Cast iron |

| 20 | Tolerance | 3m+-1.5mm |

| 21 | Electric Source | 380V, 50HZ,3 phase According to customer's require |

| 22 | Way Of Drive | By gearbox |

| 23 | Color Of The Machine | Yellow and blue |

Main Component:

Our Advantage: