Wuxi Luole Machinery Co., Ltd |

|

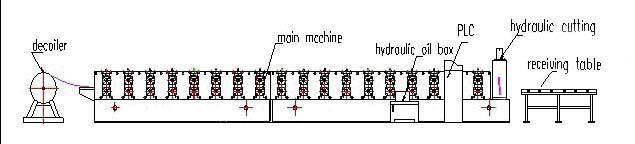

Countryside Road Construction Crash Barrier Guardrail Forming Machine Gearbox Driven 3 mm Plate Thickness

The expressway fence is the main form of a semi-steel fence, which

is a continuous structure that is stitched with a corrugated steel

guardrail and supported by the main pillar.

When the vehicle collides with it, it is not

easy to be crashed because of the good impact resistance and energy

absorption of the corrugated steel guardrail, and it can also

protect the vehicle and the crew.

Specifications:

| Item NO | Description | Offered specification |

| 1 | Roll Forming Machine | Guard rail |

| 2 | Material Width | According to the profile |

| 3 | Rolling Speed | 5-12m/min |

| 4 | Rolling Thickness | 2.0-3.2 mm |

| 5 | Control System | PLC (Panasonic) as list in the note |

| 6 | Un Coiler | 10 ton hydraulic de-coiler |

| 7 | Pre-cutting | The first big punching adopt double cylinders, the other three punching adopt single cylinder |

| 8 | Leveling Station | Upper is 3 rollers, down is 4 rollers (total is 7 stations), material is 40Cr steel, HRC48-52°, 7.5kw |

| 9 | Punching | Four sets |

| 10 | Cutting mode | Hydraulic pre-cutting |

| 11 | Material Of Cutting | Cr12Mov quenching 58-62ºC |

| 12 | Hydraulic Station Power | 22kw |

| 13 | Hydraulic Pressure | 25Mpa |

| 14 | Conveyor table | 3KW, 6 meters |

| 15 | Roller Stations | 20 stations (according the final design) |

| 16 | Roller Material | GCR15, HRC58-62ºC, coated with chrome |

| 17 | Shaft Material and DIA | ¢100mm, material is 45# forge steel |

| 18 | Maim Motor Power | 55kw |

| 19 | Structure Of The Stations | Cast iron |

| 20 | Tolerance | 3m+-1.5mm |

| 21 | Electric Source | 380V, 50HZ,3 phase According to customer's require |

| 22 | Way Of Drive | By gearbox |

| 23 | Color Of The Machine | Yellow and blue |

Techical description:

1.De-coiler

1) Type:Manual

2) Loading 5T. Inner diameter of coil: φ508mm,

3) Maximum diameter of coil: φ2000m

2.Flatting device

The wall plate type seven roller flatter, two rollers clamp

deliver, five rollers for leveling.

3.Punching device

1) Using type Yl32-315 4 pillar hydraulic pressure puching machine,

2) Hydraulic pressure power: 11kw.

3) Material of blade mould & plunger chip is alloy steel Cr12

4.Forming machine:

1) Forming racks: 13sets

2) Width of machine: 550mm

3) Material thickness:3mm

4) Shaft diameter:80mm

5)Roller material:45# steel polished and coated with chrome

HRC55-60°

6)Shaft material:high grade No.45 steel after treatment

7)Power of main machine: 55kw

8)Driven type:1.5 inch double chain

5)Cutting device

Material for Cut-Off Modular:Cr12 steel

Hardness for Heat Treatment:HRC55 – 60°

Cut-Off Type:Hydraulic, Automatic Cut-Off

Cut-Off Modular:1 set

Motor for Hydraulic Stand: 11kw

6)Control system:

Type: PLC Frequency Control System with touch screen

PLC Brand: Japan Panasonic

Encoder Brand: Omron

Length Error: ±2mm

7)Output table

It is simple and used to load finished product.

Length:6m

Main Component

Our Advantage