Wuxi Luole Machinery Co., Ltd |

|

High Quality Automated Corrugated Roofing Sheet Roll Forming Machine / Glazed Roof Panel Making

Machines

Main ordered items

| Model: | RLRT-1250-18 -Trapezoidal | Material: | Color Steel, Iron, G.I Coils |

| Material Thickness: | 0.3-0.8mm | Weight Capacity Of Decoiler: | 5 Ton |

| Axis Diameter: | Φ76mm | Forming Speed: | 0-20 M/min |

Remarks: 1250--the feeding coil plate width; 18--Forming Stations

Features of Roof Panel Forming Machine

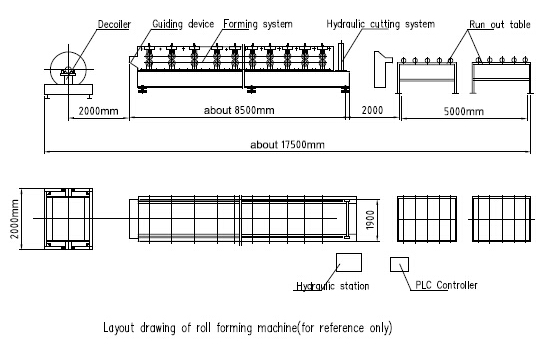

Layout drawing of machine

Main Specifications of Roofing Roll Forming Machine

| Item | Steel Roof Sheet Roll Forming Machine | |

| Coil Material | Coil width | Custom-made, 1000/1200 /1250 mm |

| Sheet thickness | 0.3-0.8 mm | |

| Yield Strength | 350-500 Mpa | |

| Material | PPGI, Color Steel, GI. | |

| Decoiler / Uncoiler | Decoiler Type | Manual or Hydraulic or Auto Type |

| Coil Weight | 5 tons | |

| Coil Width | Max. 1250mm | |

| I.D | 440-530mm | |

| O.D | Max.1500mm | |

| Steel roof forming machine | Forming Stations | 13-22 Stations ( Depend on Profiles ) Usually:18 Stations |

Roller material | 45# steel, surface coated with 0.05mm hard chrome | |

| Diameter of shaft | 76mm | |

| Shaft material | High grade 45# steel | |

| Drive type | Chain transmission---16A | |

| Sprockets | Quenched and black treated | |

| Forming speed | 0-20m/min | |

| Speed adjust | Panasonic VFD | |

| Main power | 5.5KW | |

| Cutting | Cutting type | Hydraulic Scissor cutting |

| Cutting Die Material | Cr12Mov steel, HRC58-62 | |

| Cutting power | 4 KW (Hydraulic station) | |

| Cutting Tolerance | 10m+/-1.5mm | |

| Encoder | OMRON Brand | |

| Electrical control | PLC | Panasonic Brand |

| Inverter | Siemens Brand | |

| Touch screen | Panasonic | |

| Operation type | Touch screen & Button | |

| Main units | Schneider | |

| Hydraulic Station | Hydraulic Units | Famous Chinese brand |

| Runout Table | Table type | Simple non power type |

| Function | To support the finished panel | |

Main Components Of Steel Roof Roll Forming Machine

| 5 Tons Passive Decoiler / Uncoiler | 1 Unit |

| Feeding Guide Device | 1 Unit |

| Main Steel Roof Roll Forming Machine | 1 Unit |

| Hydraulic Cutting Device | 1 Unit |

| Hydraulic Station | 1 Unit |

| PLC Computer Control Board | 1 Unit |

| Output Table | 2 Units |

Reference Roof Profile Drawings

Applications

Construction,Store Fixture,Metal roof wall cladding, roof wall

panel, Metal Roof sheet, trapezoidal roof metal, trapezoidal

roofing, trapezoidal panel,corrugated roofing, corrugated

panel,metal roof; steel roof; metal roof wall panel; steel roof

wall panel; metal roofing sheet; steel roofing sheet; metal roof

panel; steel roof panel; roof wall cladding; roof cladding; wall

cladding,wall panel,

Why you choose our productions

1. Anti-rust roller: CNC machine tooled, Plated with 0.05mm hard

chrome .to protect surface shiniing and strong

2. Heat treatment: Heat treatment for cutting frame to remove the

steel stress, to avoid deformation.and hardness 60 degree.

3. Cutter blade: Cr12 mould steel with quenched treatment, long

life time.

4. High precision: shafts for rollers are tooled by grinding

machine. Rollers are CNC processed to ensure precision performance.

5 .automatic PLC : introduced Mitsubishi PLC with touch screen

,inverter,transformer.

6. Excellent services: Technician can be sent to your factory to

install the machine and train your workers. Lifttime services for

our machines.