Botou Xinchen Environmental Protection Equipment Co., Ltd. |

|

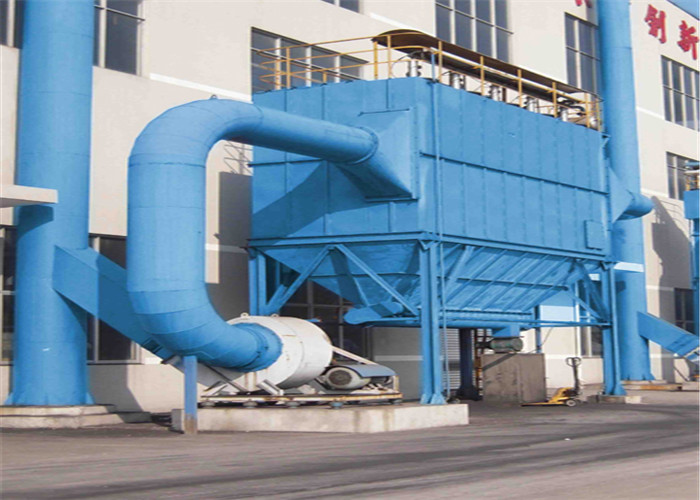

31200m3/H Industrial Dust Collector With Excellent Filter

Efficiency

Features:

(1) Imported cellulose fiber or synthetic fiber for base

media (80%cellulose and 20%polyester).

(2) Excellent filter efficiency.

(3) Wide pleat spacing, great filter surface.

(4) Electrochemical plate top and bottom, no rust

(5) Perforated zinc galvanized metal inner core, allows good airflow.

(6) Specialty chlorine rubber gasket to ensure airtight sealing.

(7) Applicable temperature: 65°C.

Techinal parameters

| model | PPC32-3 | PPC32-4 | PPC32-5 | PPC32-6 | PPC64-4 | PPC64-5 | PPC64-6 | PPC64-7 | PPC64-8 | |

| Handling air volume (m3/h) | 6900 | 8900 | 11160 | 13390 | 17800 | 22300 | 26700 | 31200 | 35700 | |

| Filtration wind speed (m/min) | 1.2-2.0 (select different purification filter wind speeds according to different dust points) | |||||||||

| Total filtration area (m2) | 93 | 124 | 155 | 186 | 248 | 310 | 372 | 434 | 496 | |

| Net filtration area (m2) | 62 | 93 | 124 | 155 | 186 | 248 | 310 | 372 | 434 | |

| Number of dust collectors (units) | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 | |

| Total number of filter bags (bars) (pcs) | 96 | 128 | 160 | 192 | 256 | 320 | 384 | 448 | 512 | |

| Dust collector resistance (Pa) | 1470-1770 | |||||||||

| The dust collector is subjected to negative pressure (Pa) | 5000 | |||||||||

| Imported gas dust concentration (g/m3) | <200 | <1000 | ||||||||

| Exhaust gas dust concentration (g/m3) | <0.1 | |||||||||

| Ash pressure Shrink air | Pressure (Pa) | (5-7)×105 | ||||||||

| Air consumption (m3/min) | 0.27 | 0.37 | 0.46 | 0.55 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | |

| Pulse valve | amount) | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

| Specifications (inches) | 1-1/2′′ | 2-1/2′′ | ||||||||

| Poppet valve (with cylinder) | amount) | 3 | 4 | 5 | 6 | 4 | 5 | 6 | 7 | 8 |

| Specification (mm) | Lifting valve plate diameter Φ460, cylinder diameter Φ63 | Lifting valve plate diameter Φ595, cylinder diameter Φ100 | ||||||||

| Star unloading device YJD-16 | Feeding port 300×300, height 400mm, speed 41r/min, gear motor power 1.5kW, output 39.4m3/h | |||||||||

| Screw conveyor | specification | no N/A | Diameter Φ300, output 30m3/h (filling rate Φ=0.7) | |||||||

| Reducer | no N/A | Model XWD2.2-5-1/59, power 2.2kW | ||||||||

| Filter bag specifications and materials | Diameter × length Φ130×2450, polyester needle felt weight 450g/m2, use temperature 120°C | |||||||||

| Insulation area (m2) | 26.5 | 34 | 41 | 48.5 | 70 | 94 | 118 | 124 | 166 | |

| Total weight of equipment (approximate value) (Kg) | 3110 | 4400 | 5700 | 7000 | 8940 | 10750 | 12570 | 14380 | 16200 | |

Note:

1. The net filtration area in the table refers to the filtration

area when a room is cleaned. The total weight of the equipment does

not include the weight of the insulation layer.

2. The gas consumption in the table refers to the situation of

centralized gas supply in the factory. If a separate air compressor

is set, the gas consumption in the table is multiplied by 1.3.

Equipment advantages

▲Clean the dust more thoroughly

The off-line three (filtering, cleaning, static) cleaning method is

adopted to avoid the "re-adsorption" of cleaning.

▲More flexible design

According to the requirements of the working conditions, the

settling chamber can be designed to increase the life of the filter

bag, and the dust concentration can be as high as 1000g/Nm3.

▲Control is more convenient

Adopt PLC program or special pulse controller to control the dust

removal, and it can be timed and manually, which ensures the dust

removal effect of the air compressor.

Timing description: set the time program to automatically clean the

dust from room to room

Manual instructions: Automatic control is adopted during normal

work. When a single machine fails, the manual control can be

switched randomly to avoid changing the program and causing too

much ash accumulation in the ash hopper, causing the auger to jam

or causing the dust to accumulate in the pipeline, reducing the

suction effect and causing the pipeline to block.

▲Lower cost

Separate chamber spraying and cleaning: One pulse valve can spray

one chamber at the same time (the number of filter bags has 32, 64,

96 specifications series). Compared with ordinary dust collectors,

one valve blows six bags, and the number of pulse valves is reduced

by 6-20 times.