Guangzhou Nanya Pulp Molding Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Full Auto Reciprocating Waste Paper Egg Tray Making Machine Vacuum Suction Forming

Specifications:

Model Type | EW2500-A |

Capacity | 2800 pcs/hour |

Workshop Requirement | 600 m2 |

Electricity Consumption | ~140 kw |

Electricity Installed | 210 kw |

Material Consumption | 170~180 kg/h |

Water Consumption | 600~700 kg/h |

Worker Requirement | 5~6 persons |

Container Requirement for Shipment | 6 x 40 HQ |

Forming Machine (Reciprocating Type) | Plate Size 2400*800 mm 12 pcs/time |

Drying Line | 30x3.4x2.4 m 1-Layer |

Remarks: | |

Fuel Consumption (One Item Selectable)

Natural Gas | 60~70 m3/h |

LPG | 20~24 m3/h |

Diesel | 50~60 kg/h |

Heavy Oil | 52~62 kg/h |

Steam | 1.2~1.3 ton/h |

Wood | 210~240 kg/h |

Coal | 160~180 kg/h |

Description:

Applications:

Egg tray | 20,30,40packed egg tray… quail egg tray |

Egg carton | 6, 10,12,15,18,24 packed egg carton… |

Agricultural products | Fruit tray, seeding cup |

Cup salver | 2, 4 cup salver |

Disposable Medical Care Products | Bedpan, sick pad, female urinal… |

packages | Shoe tree, industrial package… |

| |

Competitive Advantage:

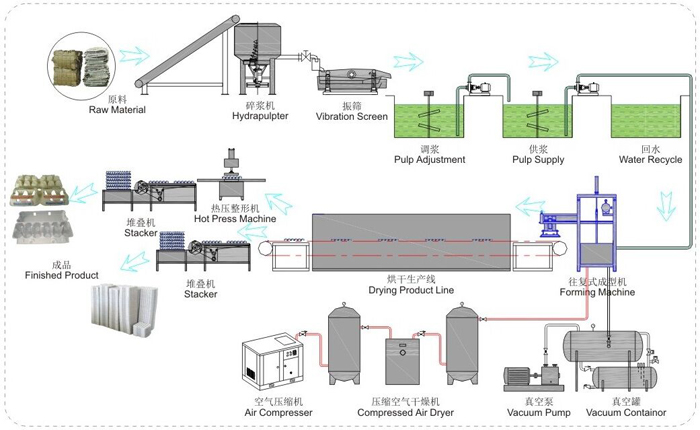

Schematic Diagram:

Working theory:

Business Terms

NO. | ITEM | DESCRIPTION |

1 | Payment Terms | 30% down payment by T/T, 70% before shipment by T/T or L/C at sight |

2 | Delivery Terms | FOB Guangzhou, China. (Final transaction could be made in C&F or CIF, the freight and insurance should be decided according to the current rate when signing the contract). |

3 | Delivery Time | 45-75 days |

4 | Packages | Packages suitable for ocean transport. The small parts are packaged by wooden boxes. The big parts are protected by wooden support. |

5 | Installation | Seller should appoint 2 engineers to instruct buyer for installation, test-run and training. All the charges including air ticket, VISA , accommodation and food of the engineers should be responsible by buyer. Besides, the buyer should pay the engineers subsidy of USD50/person/day and offer translation service. |

6 | Warranty | 12 months after installation |

7 | After service |

|

8 | Quotation Validity | 90 days after the offering date |