Guangzhou Nanya Pulp Molding Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Disposable Semiautomatic Paper Pulp Molding Dishware Making Machine

Specifications:

Model Type | BY010 |

Product Name | Semiautomatic Dishware Forming Machine |

Mould Plate Size | 900×580 mm |

Quality of Forming Plate | 1 set |

Quality of Press Plate | 2 sets |

Forming Method | Vacuum Forming |

Drying Method | Thermal Forming |

Heating Method | By Electricity or Conduction Oil or Steam |

Maximum Heating Power | 50kw |

Descriptions:

Production Information and Our Warranty:

Applications:

Food container | Dishware, tableware, lunch box, bowls… |

| |

Artware | Mask, Christmas balls, Easter Eggs, boutiques… |

| |

Decoration material | Wall decoration painting |

| |

Competitive Advantages:

Business Terms

NO. | ITEM | DESCRIPTION |

1 | Payment Terms | 30% down payment by T/T, 70% before shipment by T/T or L/C at sight |

2 | Delivery Terms | FOB Guangzhou, China. (Final transaction could be made in C&F or CIF, the freight and insurance should be decided according to the current rate when signing the contract). |

3 | Delivery Time | 45-75 days |

4 | Packages | Packages suitable for ocean transport. The small parts are packaged by wooden boxes. The big parts are protected by wooden support. |

5 | Installation | Seller should appoint 2 engineers to instruct buyer for installation, test-run and training. All the charges including air ticket, VISA , accommodation and food of the engineers should be responsible by buyer. Besides, the buyer should pay the engineers subsidy of USD50/person/day and offer translation service. |

6 | Warranty | 12 months after installation |

7 | After service |

|

8 | Quotation Validity | 90 days after the offering date |

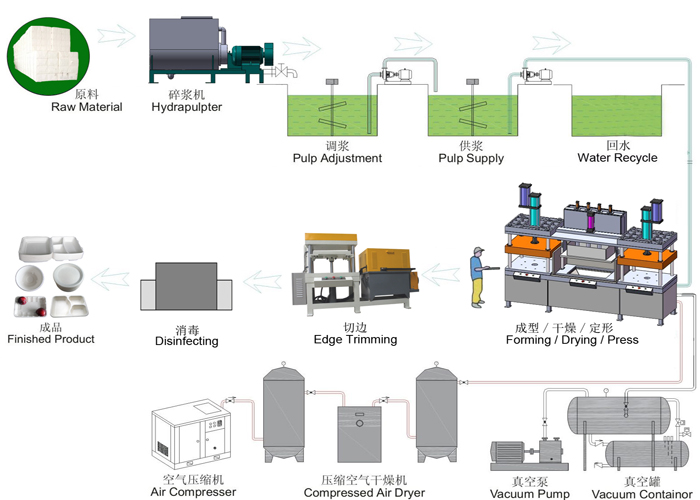

Schematic Diagram: