Dongguan Linkun Electronic Technology Co., Ltd. |

|

Verified Suppliers

|

|

Diameter 5mm 75C 300~500 Ohms (400R±25%) PTC Thermistor Power Supply, Ballast

MZ5 series PTC thermistors are used in all kinds of fluorescent lamp electronic ballasts and electronic energy-saving lamps. There is no need to change the circuit and the product is directly connected to the two ends of the resonant capacitor of the lamp tube, which can change the electronic ballast and electronic energy-saving lamp. The hard start is the preheating start, and the preheating time of the filament is 0.4~2 seconds, which can extend the life of the lamp more than 4 times.

The MZ5 series produced by Tianrui Electronics covers the entire series from 3 watts to 85 watts, and can develop special specifications of PTC thermistors according to customer requirements.

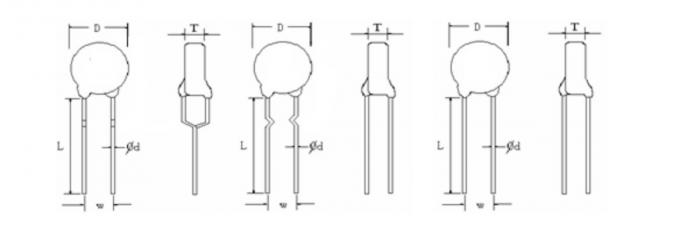

Number | Name | Technical Requirements | Leads | |||||||||||

| D | Diameter of Resistance | 5.0max | □ Straight □ Axis Formed ■In-Forming | |||||||||||

| T | Thickness of Resistance | 4.5max | ||||||||||||

| L | Length of fuse | Min20 | ||||||||||||

| W | Distance between fuses | 5.0±0.5 | ||||||||||||

| d | Diameter of fuse | 0.5±0.05 | ||||||||||||

Coating

| Coating | Material | Color | |||||||||||

| □ No coating ■ Coating | ■ PF resin □ Silicon | ■ Yellow □ Green | |||||||||||

| Number | Items | Technical Requirements | Test Conditions | |||||||||||||

| 3-1 | Resistant for Zero Rated Power | 300-500Ω±2% | Atmosphere Temperature:25±2℃Accuracy of the Test:±0.5% | |||||||||||||

| 3-2 | Over Voltage Withstanding | ≥600V Δ R/Rn≤20% | Starting Current:≥200mA, Starting Voltage:220VAC,hold on for 7s,and then change to high voltage800VAC,for 6s.the is shown as follows: Stay under the conditions of regular temperature and humidity for 4-5 hours, and then check the Rn again. | |||||||||||||

| 3-3 | Over Current withstanding | ≥400mA Δ R/Rn≤20% | Starting Current: ≥ 400mA,Voltage 220VAC, switch on the circuit for 1 minute after every 5minutes, switch-off, and repeat this operation for 20 times. Put it under the conditions of regular temperature and humidity for 4-5 hours and then check the Rn again | |||||||||||||

| 3-5 | Curie Temperature | 75℃ | Check the temperature at 2 times Rn. | |||||||||||||

Number | Items | Technical Requirements | Test Conditions | ||||||||||||||

| 4-1 | Appearance | No noticeable defect, such as, bubbles and micro holes, etc; NO visible damage that may reduce its performance; the symbol is clear | Visual Check | ||||||||||||||

| 4-2 | Welding | It's tinned evenly and with smooth welds, and the tinned area 95% | Do the test according GB2423-28 of Ta, put welding aid on the faze end and soaked it into the 230℃ tin solution with only 5mm distance to the PTC body above the solution, and maintain for 3-5s. | ||||||||||||||

| 4-3 | Heat Resistance | Check the variation rate of resistance before and after the test Δ R/Rn≤20% | Do the test according to GB2423-28 of Tb stsy under the regular temperature and humidity for 4-5 hours, and then check the Rn again.Dipping terminals to a depth of 15mm in a soldering bath of 255℃± 10℃,and to the place of 6mm far from PTC boby for 3±0.5s | ||||||||||||||

| 4-4 | Intensity at Fuse end | Check the variation rate of resistance before and after the test Δ R/Rn≤20% No break out | Do the test according to GB2423-29 of U Test Ua: Fasten the body and apply a force gradually to each lead until 10N and then keep for 10sec.hold the body and apply a force to each lead until 90° slowly at 5N in the direction of lead axis and then keey for 10sec,and do this in the opposite direction repeat for other terminal. | ||||||||||||||

Contact Details:

Nancy Huang

Email: huangju@lk-ptc.

Tel/Whatsapp: +86 13423305709

Wechat: LinKun_Nancy2013

QQ: 1078049901