Dongguan Linkun Electronic Technology Co., Ltd. |

|

Verified Suppliers

|

|

AMT Thermal Protector Open Ceramic Overheat Protector Thermostat For Hair Dryer

1.Used in various motors, induction cookers, vacuum cleaners, coils, transformers, electric heaters, ballasts, electric heating appliances, fluorescent

BW-C series thermal protectors have the characteristics of small size, insulated shell, sensitive action, long life, etc., and are widely suitable for

2. Structural features:

The BW-C series thermal protector uses a bimetallic piece with a certain geometric shape. It does not require an auxiliary mechanism. It only relies on the bimetallic piece's own temperature and current thermal effects to rapidly change the state of the bimetallic element and directly drive the contacts.

It can automatically cut off and connect the circuit to protect against overheating and overload.

3. Product model and classification:

4. Rated operating temperature,

4.1 Plastic shell:29mm×9mm×5mm

4.2 Metal shell: 3.2mm×6.7mm×16mm

5. Appearance

5.1 The outer shell of the thermal protector must not have burrs, cracks, deformation, rust, etc.;

5.2 The signs should be correct, upright, clear, durable and scratch-resistant;

6.Performance

6.1 Rated electrical

Rated current: AC250V/10A AC115V/5A,

Maximum short circuit current: DC 12V 100A

Minimum current: DC 5V 10Ma

6.2 Operating temperature:

Operating temperature (OFF): ±5℃

Reset temperature (ON): The operating temperature drops by 15℃-45℃

ON——OFF difference: above 15℃

Temperature characteristics comparison table (see table below):,

| Dongguan Linkun Electronic Technology Co., Ltd. | |||||

| Product number | Operating temperature(℃) | Reset temperature(℃) | Product number | Operating temperature(℃) | Reset temperature(℃) |

| BW-B(K)S-50℃ | 50±5 | 30±8 | BW-B(K)S-105℃ | 105±5 | 70±15 |

| BW-B(K)S-55℃ | 55±5 | 35±10 | BW-B(K)S-110℃ | 110±5 | 75±15 |

| BW-B(K)S-60℃ | 60±5 | 40±10 | BW-B(K)S-115℃ | 115±5 | 75±15 |

| BW-B(K)S-65℃ | 65±5 | 45±10 | BW-B(K)S-120℃ | 120±5 | 80±15 |

| BW-B(K)S-70℃ | 70±5 | 45±15 | BW-B(K)S-125℃ | 125±5 | 85±15 |

| BW-B(K)S-75℃ | 75±5 | 50±15 | BW-B(K)S-130℃ | 130±5 | 90±15 |

| BW-B(K)S-80℃ | 80±5 | 55±15 | BW-B(K)S-135℃ | 135±5 | 95±15 |

| BW-B(K)S-85℃ | 85±5 | 55±15 | BW-B(K)S-140℃ | 140±5 | 100±15 |

| BW-B(K)S-90℃ | 90±5 | 60±15 | BW-B(K)S-145℃ | 145±5 | 105±15 |

| BW-B(K)S-95℃ | 95±5 | 65±15 | BW-B(K)S-150℃ | 150±5 | 110±15 |

| BW-B(K)-100℃ | 100±5 | 65±15 | Special specifications can be customized according to customer requirements | ||

6.3 Contact resistance:

When the contacts are in the closed state, the contact resistance between the two contacts of the thermal protector should not be greater than 50mΩ.

6.4 Insulation resistance:

The insulation resistance is above 100MΩ.

6.5 Electrical strength

Apply a basic sine wave test voltage (effective value) with a frequency of 50Hz between the following parts of the thermal protector. There should be no flashover or breakdown phenomenon after 1S.

In the thermal disconnection state of the contacts, between two lead wires: 500V

When the contacts are normally closed, between the lead wire and the surface of the insulation layer of the shell: 1500V

6.6 Moisture resistance

After being placed in an ambient temperature of 25°C and a relative humidity of 95% for 10 hours, it meets the requirements of items 6.4 and 6.5, and there are no abnormal changes in the appearance structure.

6.7 Circulation heating

Place it in the temperature of -20℃ and +90℃ every 2 hours. After 10 cycles, it meets the requirements of 6.4 and 6.5 and there is no abnormal change in the appearance structure.

6.8 Heat resistance

After being placed at 140°C for 10 hours, the requirements of items 6.4 and 6.5 are met, and there is no abnormal change in the appearance structure.

6.9 Cold resistance

After being placed at -20°C for 10 hours, the requirements of items 6.4 and 6.5 are met, and there is no abnormal change in the appearance structure.

6.10 Repeated opening and closing durability

At normal temperature, after 2000 tests under rated load conditions of AC 50Hz, voltage 220V, and power factor COS∮=0.7, the rated operating temperature should be within ±5°C of the initial value, and the contacts should not be welded. Continue the test. The thermal protector should still work after 5,000 times.

6.11 Vibration resistance

For a fixed-frequency test with a vibration frequency of 50Hz, an amplitude of 0.35mm, and a duration of 90S, the rated disconnection temperature after the test shall comply with the provisions of 6.2.

6.12 Drop impact resistance

After being dropped to the concrete floor from a height of 1200mm three times, there was no abnormal change in its appearance and structure.

The operating temperature is within 5℃.

6.13 Lead pulling strength performance:

Use an axial static pulling force of no less than 30N for 5 seconds, and there will be no breakage, loosening or falling off of the leads.

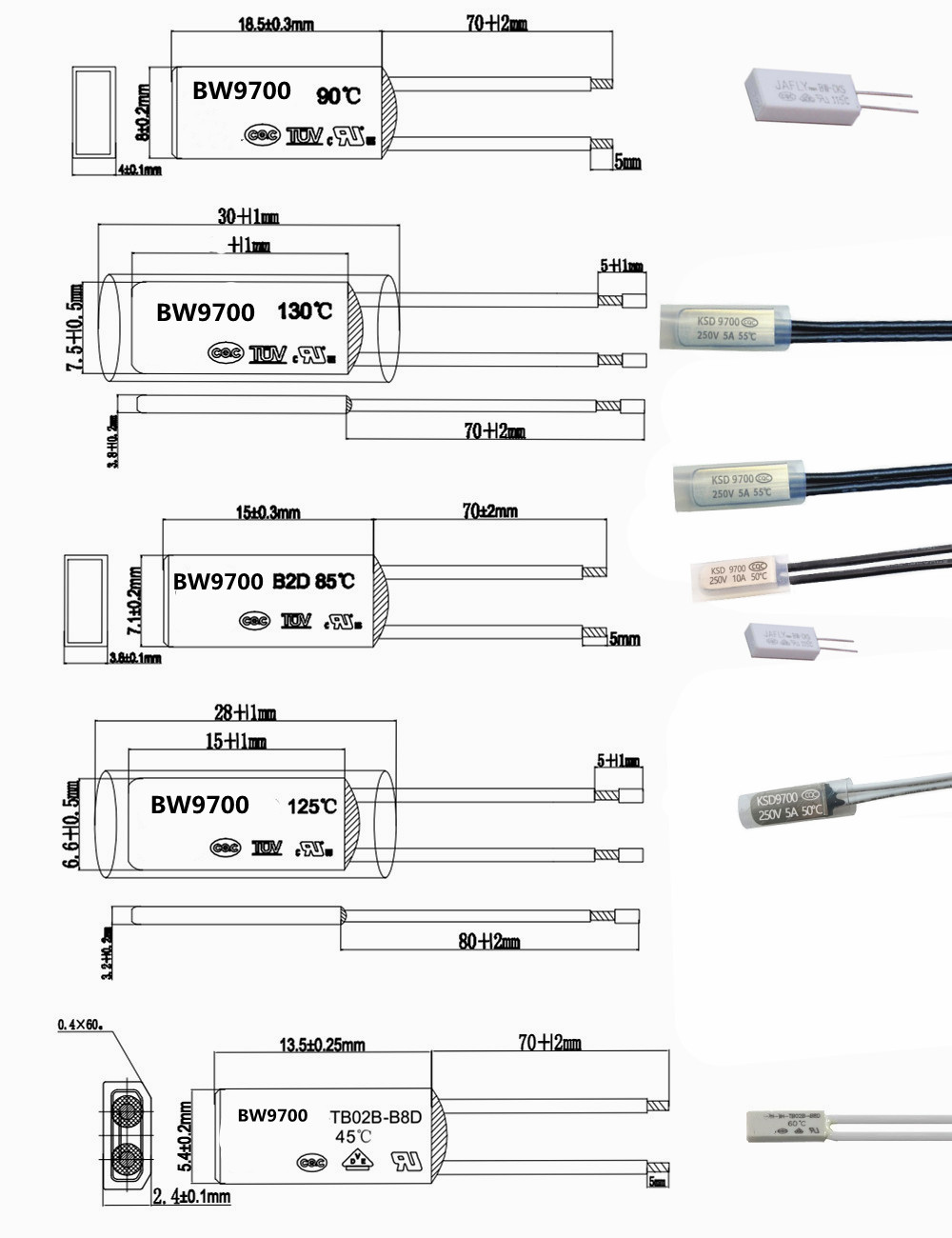

7.0 Logo: Product model, operating temperature, certification mark, etc. are shown in the figure below.

Remarks: The lead length is 400*400MM or added according to customer requirements.

Remarks: The lead length is 400*400MM or added according to customer requirements.

Precautions for use:

8.1 Temperature test

Place the thermal protector in a test chamber with a constant temperature accuracy of ±1°C for testing. The temperature measurement method adopts a thermocouple or thermometer. The thermocouple or thermometer should be placed on the thermal protector sample or as close as possible to the sample. During the test temperature rise process, starting from 10℃ lower than the rated operating temperature, the temperature change rate shall not exceed 0.5℃/min. The test current through the protector should not exceed 0.1A.

8.2 Usage environment

Plastic shell protectors must not be used in high temperature environments above 130°C for a long time to prevent the plastic from deforming and causing the protector to fail.

Do not use it for a long time in strong acid, strong alkali and other strong corrosive environments.,

8.3 Installation and connection

The protector should be installed at the sensitive point of the temperature rise of the protected object, and its temperature-sensing surface should be in effective close contact with the protected component or directly face the protected area.

During the installation process of the protector, in order to prevent the shell from being deformed or damaged and causing the performance of the protector to change, the following points should be noted:

When the arc welding process is used for connection, the welding current must not pass through the thermal protector, otherwise excessive current will cause damage if it passes directly through the contacts of the thermal protector.

9.0 Storage conditions:

Packaging boxes and products must not be exposed to rain or snow, squeezed or damaged during transportation and storage, and the relative air humidity should not exceed 90%.

10. Matters not covered by this standard or if customers have other requirements shall be formulated separately.

Product usage scope:

The BW-9700 Series Thermal Protector is a KSD-01F temperature control switch that provides durable, reliable temperature control with a jump thermostat. It features a high-grade plastic shell that is available in black, white, or grey color. The protector is designed with three sizes - small, medium, and large, allowing it to fit any application. This temperature control thermal protector is a must-have for anyone looking to keep their work area safe and secure from heat-related damage.

| Parameter | Value |

|---|---|

| Name | BW-9700 Series Thermal Protector |

| Type | Temperature Controller |

| Size | Small/Medium/Large |

| Material | Plastic Shell |

| Durability | High |

| Heat Resistance | -20~+125°C |

| Color | Black/White/Grey |

Heat Protector – LINKUN BW-9700 Series Thermal Protector

The Heat Protector LINKUN BW-9700 Series Thermal Protector is the perfect choice for those seeking high durability and reliable temperature control. This product is certified with CQC, UL, RoHS, and VDE, and is available in black, white, and grey color options. It has an ultra-small 02B temperature switch and a 17AM sudden jump thermal protector, making it extremely reliable and durable. It is made of plastic shell, with a range of sizes available, from small to large. It is also a cost-effective product, with a minimum order quantity of 1000 and a flexible pricing system.

The Heat Protector LINKUN BW-9700 Series Thermal Protector is designed to provide a secure and reliable temperature control system. It offers a high level of durability and a wide range of sizes to meet any temperature control needs. It also has a flexible pricing system and a minimum order quantity of 1000, making it an ideal choice for those seeking a reliable and cost-effective temperature control system. With its UL, RoHS, and VDE certifications, this product is sure to provide reliable and safe temperature control.

For those seeking reliable and cost-effective temperature control, the Heat Protector LINKUN BW-9700 Series Thermal Protector is the perfect choice. With its UL, RoHS, and VDE certifications, and its wide range of sizes and colors, this product is sure to provide reliable and safe temperature control. It is also an extremely cost-effective product, with a minimum order quantity of 1000 and a flexible pricing system.

Heat Protector with Brand Name LINKUN and Model Number Temperature control switch Thermal protector is made in China DongGuang and certified by CQC,UL,RoHS,VDE. The minimum order quantity is 1000 and the price is negotiable. The packaging details and delivery time are also negotiable. The payment terms are T/T or other forms of negotiation. The supply ability is 1,000,000 pieces/month. The material of the shell is plastic, and its heat resistance is -20~+125°C. The size is small, medium or large with color options of black, white and grey. It has high durability and is perfect for high current ceramic temperature control switch, KSD-01F temperature control switch, Jump thermostat thermal protector.

We offer a comprehensive technical support and service plan that covers your Heat Protector for the full duration of its lifespan.

Our team of trained technicians are available 24/7 to answer any questions or concerns you may have. We can provide advice, troubleshooting tips, and assistance with any issues related to your Heat Protector.

We also offer a one-year warranty for your Heat Protector. In case of any defects or malfunctions, we will repair or replace your Heat Protector free of charge.

If you require any additional assistance, please feel free to contact us via email at support@heatprotector.com or by phone at 888-888-8888.

Heat Protector is packaged and shipped in strong corrugated boxes designed to protect the product during transit.

Each box contains a product description, product safety instructions, and contact information.

Heat Protector is shipped with a tracking number to ensure that it arrives in perfect condition.