Changzhou Prostepper Co.,Ltd. |

|

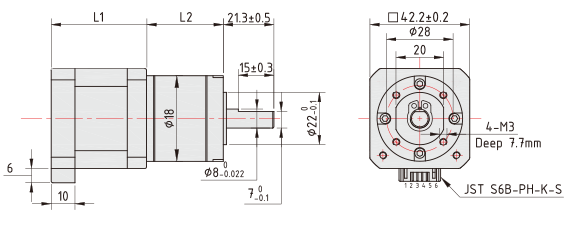

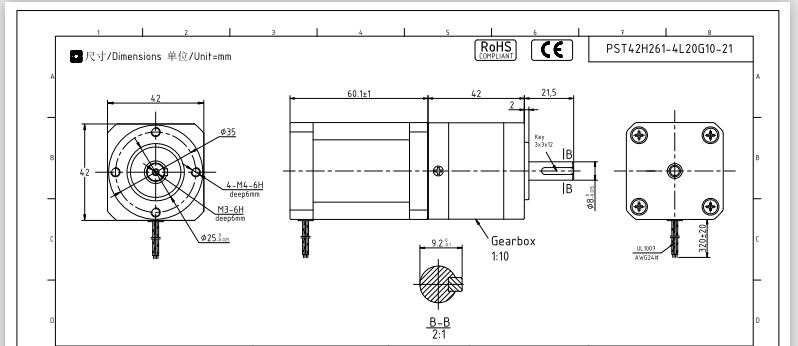

1.8 Degree Gear Box Type Stepping Motor Nema17 Hybrid Stepper Motor 42mm

Gear Box Stepper Motor features

specifications

| Number of phase | 2 |

| Basic step Angle | 1.8 degree |

| Rated Current | 2.0A |

| Resistance | 0.8ohm |

| Inductance | 3.7mH |

| Holding Torque | 0.72N.m |

| Weight | 0.5kg |

Description of Gear Box Stepper Motor

1. Accurate position Control

The angular displacement of the stepping motor can be precise controlled by the number of electrical pulses.Angle accuracy can be controlled within ±0.09°without any feedback devices.

2. Forward/Reverse Rotation,Pause and Hold

The forward /reverse rotation of the stepping motor can be controlled by the input sequence of the controlled electric pulses.

In the case of the a stepping motor lock(the motor winding is energized,there is no external electric pulse command),the stepping motor can still maintain a certain torque output.

3. Longer Life

Stepping motor is a mechanical structure,which does not need be changed by electric brush or Hall sensor,thus reducing the probability and increasing the motor life.Stepping motor life usually determined by the life of the bearing.

4. Strictly control the production of parts to improve the quality of parts.

5. Accurate position Control

The angular displacement of the stepping motor can be precise controlled by the number of electrical pulses.Angle accuracy can be controlled within ±0.09°without any feedback devices.

Gear Box Stepper Motor's specifications

Gear Box Stepper Motor Control by Varying Clock Pulses

Stepper motor control circuit is a simple and low-cost circuit, mainly used in low power applications. The circuit is shown in the figure,

A stepper motor is an electromechanical device it converts electrical power into mechanical power. Also, it is a brushless, synchronous electric motor that can divide a full rotation into an expansive number of steps. The motor’s position can be controlled accurately without any feedback mechanism, as long as the motor is carefully sized to the application. Stepper motors are similar to switched reluctance motors.

The stepper motor uses the theory of operation for magnets to make the motor shaft turn a precise distance when a pulse of electricity is provided. The stator has eight poles, and the rotor has six poles. The rotor will require 24 pulses of electricity to move the 24 steps to make one complete revolution. Another way to say this is that the rotor will move precisely 15° for each pulse of electricity that the motor receives.

Stepper motors are diverse in their uses, but some of the most common include: