Changzhou Dingang Metal Material Co.,Ltd. |

|

Verified Suppliers

|

|

1.Environmental Requirements: If the product will be used outdoors, especially in harsh weather conditions such as high temperatures, high humidity, or strong UV exposure, then a coating aluminum coil with high weather resistance and corrosion resistance should be selected.

2.Durability Requirements: For products that require long-term use and are often subject to wear or abrasion, such as exterior wall decoration, automotive shells, etc., a coating aluminum coil with high wear resistance and scratch resistance should be chosen.

3.Color Stability: For products that require long-term color stability and resistance to fading, such as outdoor billboards, signage, etc., a coating aluminum coil with excellent color stability and UV stability should be selected.

4.Cost Considerations: According to budget constraints and cost considerations, the most economical coating aluminum coil that meets product quality requirements can be selected. Generally, high-quality coating aluminum coils are more expensive, but they may save maintenance and replacement costs in the long run.

5.Process Requirements: Select the appropriate coating aluminum coil according to the product's processing technology and assembly method. For example, for products that require bending, stamping, or cutting, a coating aluminum coil with good bendability and formability should be chosen.

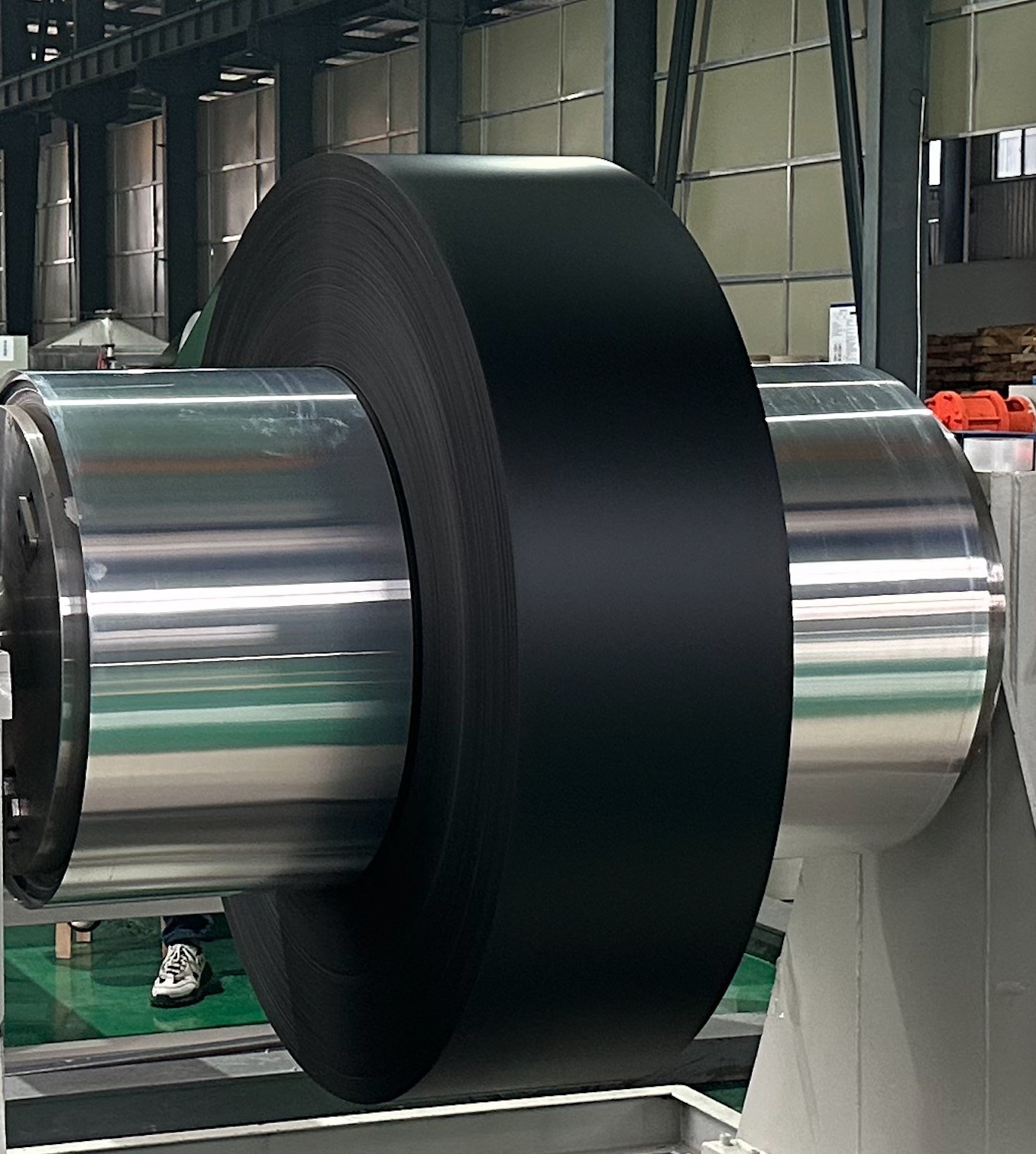

| Colored-Coated Aluminum Coil | |

| Product | Colored coated aluminum coil |

| Thickness | 0.1-5.0mm |

| Width | 30-2650mm |

| Material | 1050, 1060, 1100, 3003, 3004, 3105, 5052, 5005, 5754, 5083, 6061,8081 etc |

| Temper | O, H12, H14, H16, H18, H24, H26, H32, H34, etc |

| Inner Diameter | 405mm,505mm |

| Color | RAL, Pantone Color |

| Coating thickness | PVDF Paint Coating: Not Less Than 25um |

| PE Paint Coating : Not Less Than 18um | |

| Packing | Export Standard Wooden Pallets |

| Payment Terms | L/C at sight or 30% T/T in advance as deposit, and 70% balance against the B/L copy. |

| MOQ | 2Tons Per Specification |

| Delivery Time | Within 15-45 Days |

| Loading Port | Shanghai Port |

| Application | Aluminum Roofing,Gutter,Trim, Joints,ACP,Roller Shutter Window,Roller Shutter Door,Aluminum Ceiling,Aluminum Grilling,Aluminum Downspout System,Home Appliance's Plate, body tank of cold chain truck,high speed rail,aluminum pull ring,food packaging,outer packing case of capacitor,external contour of letter channe,Signs |

Color coated aluminum coils find applications across a diverse range of industries and sectors due to their versatility, durability, and aesthetic appeal. Some common applications include:

1.Building and Construction: Color coated aluminum coils are widely used in the building and construction industry for roofing, wall cladding, facades, and architectural accents. They offer excellent weather resistance, corrosion resistance, and durability, making them suitable for both residential and commercial buildings.

2.Transportation: Color coated aluminum coils are used in the transportation industry for manufacturing automotive body panels, trim, and components. They provide lightweight solutions that contribute to fuel efficiency and reduce vehicle weight without compromising on strength or durability.

3.Signage and Displays: Color coated aluminum coils are popular for signage and display applic

ations due to their vibrant colors, smooth finish, and excellent printability. They are used for outdoor signs, billboards, advertising panels, and indoor displays in retail stores, exhibitions, and events.

4.Appliances: Color coated aluminum coils are utilized in the manufacturing of household appliances such as refrigerators, ovens, air conditioners, and washing machines. They offer a sleek and modern appearance, resistance to scratches and stains, and ease of cleaning, enhancing the aesthetics and longevity of appliances.

5.Packaging: Color coated aluminum coils are used in packaging applications for food and beverage containers, cosmetic packaging, pharmaceutical packaging, and other consumer goods. They provide a lightweight and durable solution that protects the contents from moisture, light, and other environmental factors.

6.Interior Decoration: Color coated aluminum coils are employed in interior decoration for ceiling panels, wall panels, partitions, and furniture components. They offer a wide range of colors and finishes, allowing for creative design possibilities and customization to suit various interior styles and themes.

7.Electronics: Color coated aluminum coils are utilized in the electronics industry for manufacturing electronic enclosures, housings, and casings. They provide electromagnetic shielding, corrosion resistance, and aesthetic appeal, ensuring the protection and presentation of electronic devices.

8.Industrial Applications: Color coated aluminum coils find applications in various industrial sectors such as machinery, equipment manufacturing, and industrial machinery enclosures. They offer corrosion resistance, thermal insulation, and ease of fabrication, making them suitable for diverse industrial applications.