Zhangjiagang Bonded Area Henglong Steel Tube Co., Ltd. |

|

High strength welded steel tubes

Type: Precision welded steel tubes

Standard: EN10305-3

Steel grade: 500DP, 600DP, 800DP

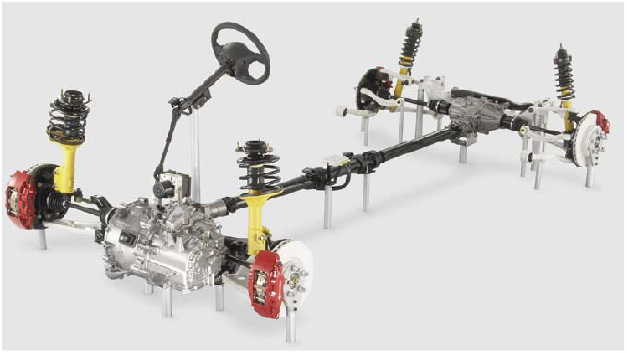

Application: Car safety components such reinforcements, seat racks.

Other steel grades and conditions are on request of clients

Chemical composition

| Steel grade | C, max % | Si, max % | Mn, max % | P, max % | S, max % | Al, max % | Nb+Ti, max, % |

| 500DP | 0.10 | 0.50 | 1.00 | 0.025 | 0.020 | 0.015 | 0.10 |

| 600DP | 0.12 | 0.40 | 1.00 | 0.025 | 0.010 | 0.015 | 0.10 |

| 800DP | 0.15 | 0.40 | 1.80 | 0.020 | 0.010 | 0.015 | 0.10 |

Mechanical properties

| Steel grade | Yield strength, Rp MPa | Tensile strength, Rm MPa | Elongation A, min % |

| 500DP | 290-370 | 500-600 | 20 |

| 600DP | 350-450 | 600-700 | 16 |

| 800DP | 500-650 | 800-950 | 10 |

Dimensional range:

OD: Up to 70mm

WT: Up to 2.1mm

Any specific size is to be discussed before offer

The tube be 100% eddy current tested

Ultrasonic test is as option

ID accuracy: H8, H9

Straightness ≤1mm/1000mm

Roughness: Ra ≤0.6

Delivery condition for availability:

| +C | Cold drawn / hard |

| +LC | Cold drawn / soft |

| +SR | Cold drawn and stress relieved |

| +A | Bright annealed |

| +N | Bright normalized |

The internal and external surface finish of the tubes shall be typical of the manufacturing process and, where applicable, the heat treatment, and it shall be such that any surface imperfections such as ridges, dents or shallow grooves requiring dressing can be identified.

Any surface imperfections, whose depth cannot be clearly identified, or,

The tubes shall have smooth outer and inner surface. The roughness Ra shall be:

≤4 μm on the outer and inner surface of tubes in the delivery conditions +C and +LC.

≤4 μm on the outer surface of tubes in the delivery conditions +SR, +A and +N.

The tubes are tested by means of following norms

EN10002-1

EN10233

EN10234

EN10246-1

EN10246-3

EN10246-7

Tubes shall be delivered with square cut ends. The ends are free of excessive burrs.

The tubes are bundled in the waterproof plastic sheet and packed in the wooden cases

The case is most suitable for hanging by forklift.

EN10204-3.1 MTC shall be issued

EN10204-3.2 MTC is as option