TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

High Creep Rupture Strength Seamless Steel Tubes and Pipes

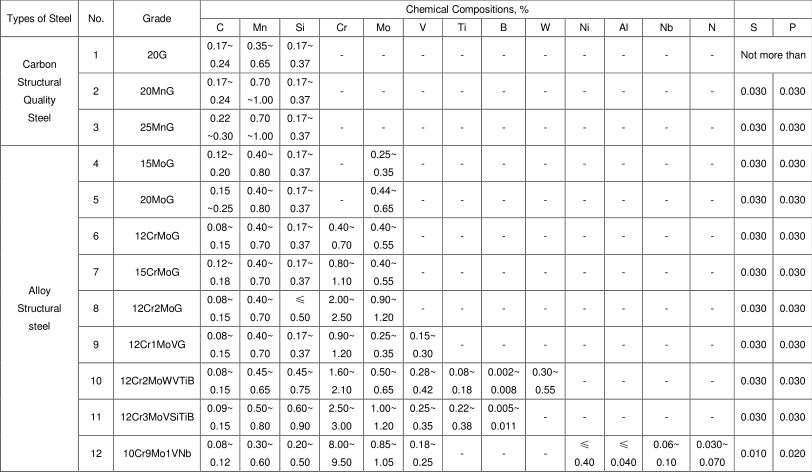

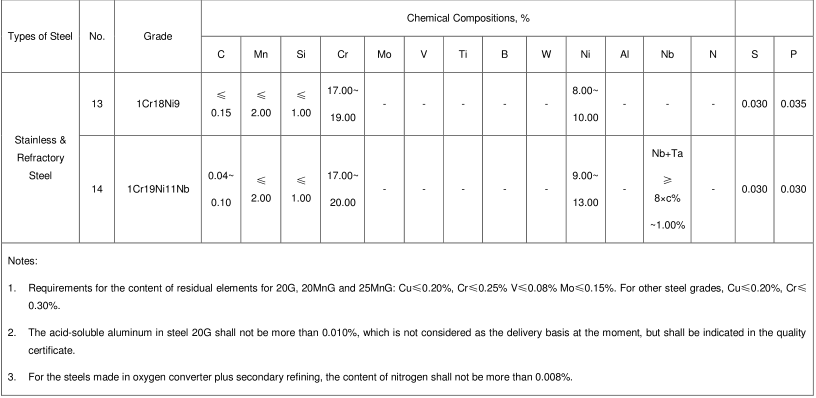

for High Pressure Boiler GB/T 5310 20G 20MnG 25MnG

TORICH is a professional manufacturer of high pressure boiler tubes, which is based on technical standard of

GB 5310, consists of steel grade 20G 20MnG 25MnG

| Producsts Name | High Creep Rupture Strength Seamless Steel Tubes and Pipes for High Pressure Boiler GB/T 5310 20G 20MnG 25MnG |

| Technical Standard | 20G 20MnG 25MnG 15CrMoG |

| Certification | ISO 9001 ISO 14001 TS 16949 |

| Size Range | OD: 3-1200mm WT: 0.5-200mm Lenth: Per Customer's Requirement. Cutting Length: according to customers PO. |

| Surface Treatment/Surface Condition | With Anti Rust Oil Protection |

| Tube Inspection | Flattening Test, Hydrostatic Test Intergranular Corrosion Test |

| Tube Application | Pipe And Tubes For High Pressure Boiler |

Characteristic of high pressure boiler steel tubes:

High Creep Rupture Strength

High antioxidant properties

Good organizational stability

Good concentricity

Good OD and ID tolerance

High Precision

Stable quality

Smooth Roughness

TORICH QUALITY ASSURANCE

Manufacturing Processing for high pressure boiler steel tubes:

RAW MATERIAL

↓

INCOMING INSPECTION

↓

STORAGE → CUTTING→HAMMERING → PICKLING LUBRICATION → CLEANING → SOAPING SURFACE

↓

ENDS CUTTING←STRAIGHTENING←HEAT TREATMENT↔MIDDLE CHECK↔ COLD DRAWING ← LUBRICATING

↓

FINAL INSPECTION→BUNDLING→STORAGE

FAQ

Q: Are you trading company or manufacturer ?

A: A professional steel pipes materials inventor, manufacturer and

solution provider

Q: How long is your delivery time?

A: Generally it is 7-14 days if the goods are in stock. or it is

30-60 days if the goods are not in stock, and it is according to

quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but you need to

pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance , balance before shippment.

If you have another question, pls feel free to contact us

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

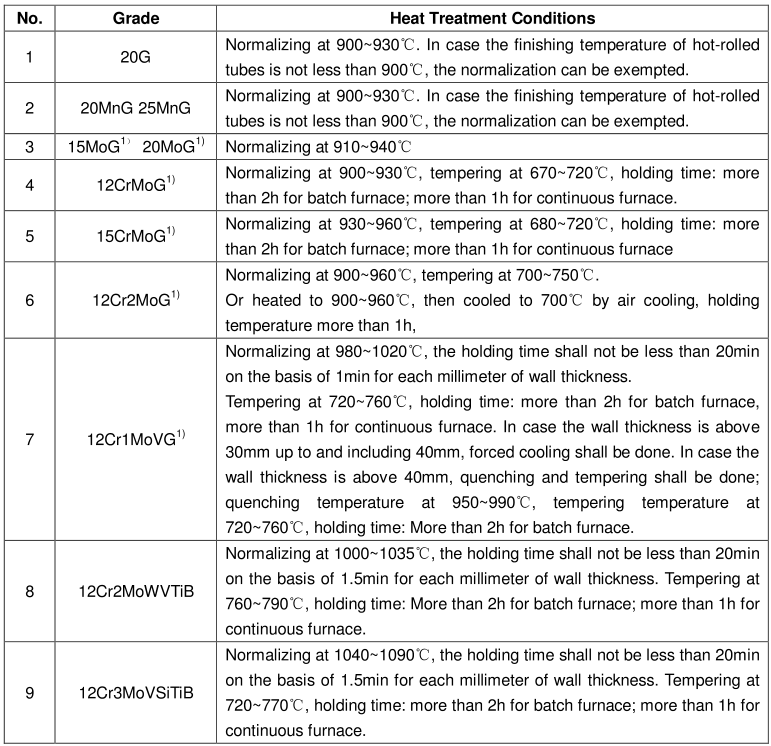

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring

Inspection

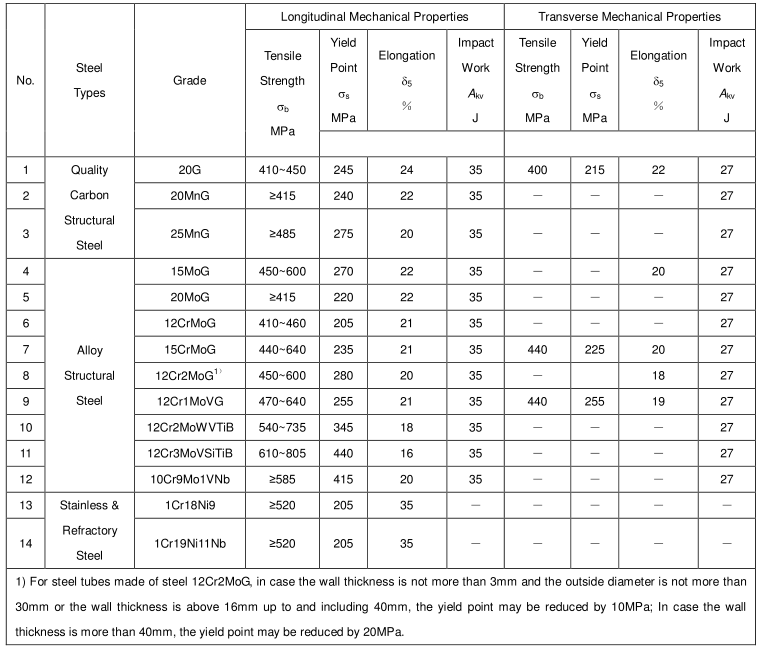

7~ Machanical Testing in own labs with Tensile Strength, Yield

Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

100% of our steel tubes are dimensionally checked

100% of our steel tubes are visually checked to assure they have a

perfect surface condition and no surface defects.

100% eddy current test and ultrosonic test to eliminate

longitudinal and transversal defects.