Precision Metal Workshop Co., Limited |

|

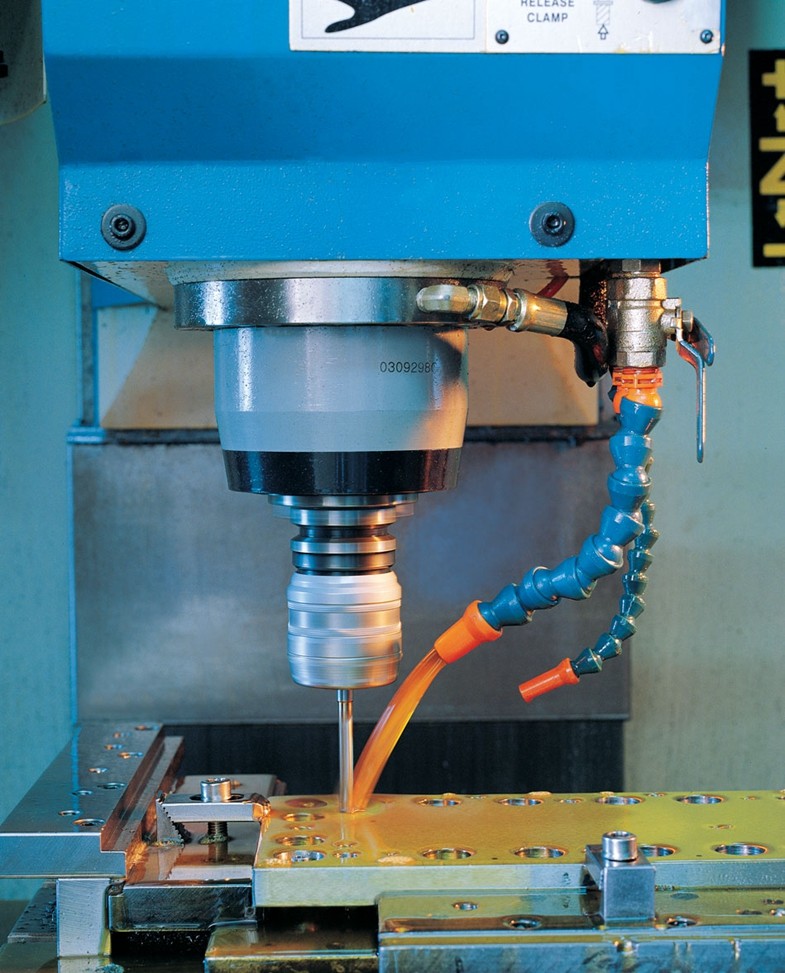

Brass Custom parts for moulds of plastic decoration parts used in automotive, high speed CNC milling.

1,Quick Detail:

Precision mould components, custom punches, steel punches, custom dies, die details. precision tooling for stamping, standard and custom tooling , precision punches & buttons for stamping ,punches, dies & shear blades for metal working and structural steel fabrication

For customers across the Steel Fabricating industry and Moulding factories.

2,Description:

Manufacture special Die Details and custom parts to your prints in a wide variety of materials with or without coatings. We are a manufacturer of precision tooling, special tooling,Mirror-Finished Punch , Die Components, Die Sections, Custom Punches and Punch Pins. It’s our mission to provide precision custom punches and dies to our customers with timely service and high quality.

3,Applications:

Industries serving:

Appliance

Bio-tech

Electronics

Food & Beverage

Furniture

General Manufacturing

Healthcare Products

HVAC

Injection Molding

Medical and Dental

Metalworking

Pharmaceutical

Sporting good

Telecommunications

Transportation

4,Specifications:

| Product | Custom punches,Custom dies,Custom die details,Stamping die details,Custom die parts of precision metal stamping dies, plastic injection moulds, precision tooling for stamping, standard and custom, tooling precision punches & buttons for stamping punches, dies & shear blades for metal working and structural steel fabrication, precision tooling, special tooling,Mirror-Finished Punch,Die Components,Die Sections | ||

| Capabilities | Capabilities include diameters ranging from 0.2 to 220 mm with tolerances down to .001mm, lengths up to 600mm, max 1 micro (Ra or RMS) surface finishes. | ||

| Material: | SKD11, DC53, D2, XW-42,ASP-23, Cr12MoV, Brass | ||

| Lead time: | 7-20 days | ||

| Processing | Wire cutting, milling, machining, grinding, polishing, hardening, laser etching for marks | ||

| Fabrication equipments: | Sodick wire cutting machine, CNC machining center, CNC turning, External cylindrical centerless grinding machines , surface grinder, laser etching device etc | ||

| Secondary Operations: | Hardening, laser etching | ||

| Surface treatment: |

| ||

| Inspection instruments: | CMM, Projector, Caliper, Surface gauge , height gauge , screw gauge | ||

| Package: | Export Carton, Wooden case, Pallet Plastic trays; or customized package | ||

| Payment Terms | T/T , L/C | ||

| Country of Origin | China (mainland) | ||

| Main Export Markets | North America, Europe, Australia etc |

5,Feature Advantage:

6,Competitive Advantage:

We’ve been in stamping die and custom die parts field for 10+ years, with rich experience on stamping die fabrication and plastic mould components. You can totally relax with the project placing to us.

The custom punches and dies we fabricated have been highly acknowledged by our local and overseas customers from Germany, Switzerland etc. For German customer we have relationship with 8 years since we started custom punches and dies business and we got 0 complaint during the 8 years!

One Stop service: We are not just specializing in custom punches and dies, mould components, but also complete set of stamping tooling. We provide services from prototype, trial production to mass production, or say, soft tooling and hard tooling production.

Q: If you make poor quality goods, will you refund?

A: We have very strict QC process, and each dimension and feature were measured honestly with QC signatures. Duplicated QC report is made, 1 send with delivery, and 1 kept by us. If there is any customer complaint, we can trace. If it is our issue, we will take our responsibility: refund or remake the parts.

Monthly capacity: 3000~15000pcs/month

Tag: plastic mould components, special tooling , Die Components

Email: sophia(at)precisionmetalworkshop.com

Skype: precisionmetalworkshop(at)outlook.com