NTT Mould Co., Ltd. |

|

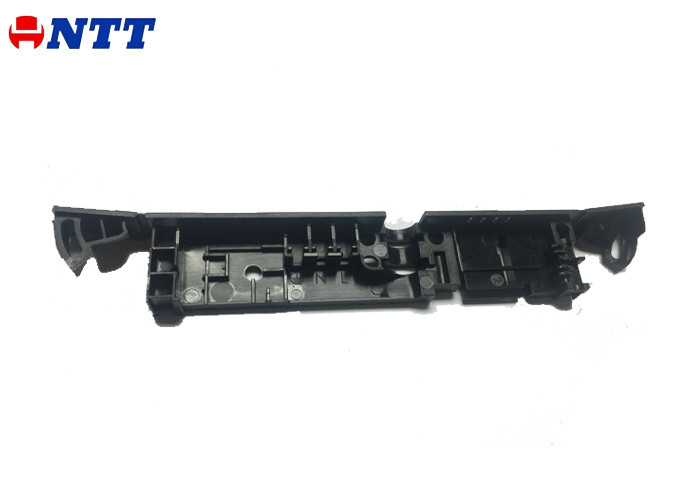

Hot Runner Electric Plastic Parts 2 Cavity Mould LKM Mold Base

NTT Gerneral Description :

| Main Business | Precise plastic injection tool/tooling, injection molding, & part assemblies. |

| Markets | We mainly exported to 90% molds North America, South American, Europe and Australia. |

| Industries | Automotive, electronics, home & office appliances, medical, etc. |

| Complex structure precision molds | Hot runner mold, over mold, two-shot mold, unscrewing mold, multi-cavity mold, etc. |

| Quality | Comply with ISO 9001:2008, we take care to control every process of design, production and inspection. |

1) Part Material:PA, POM, ABS, PC, PE, PP, PVC, Nylon, TPE, TPR etc.

2) Mold Cavity: Single or multi-cavities.

3) Mold material: Steel P20, NAK80, S136, 1045, H13, 718.718H, 2311, 2344, 8407, 2083 and so on

5) Mold Lifespan: 200,000 to 1,000,000 shots

6) Surface Finish: chrome plating, silk-printing, texture, color painting etc.

7) Nowadays,the biggest mold we can build is 1400*1100*1000mm and weight of 10 tons.

Mold tolerance 0.005 mm, Product tolerance 0.05 mm

8) The product in the picture is only for reference, we can build all kinds of injection molds as per your reqeusts.

We are your ONE STOP SHOP, from conception to design and all at a competitive price. Our highly trained staff uses state of the art technology and large equipment, allowing us to meet and exceed our customer's expectations.

We are a custom injection molding manufacturer. Our system is comprised of a highly skilled team, state of the art equipment and proprietary software that allows us to quickly convert your 3D part data into a high quality injection mold faster than anyone else.

With our in house developers we have developed software to significantly increase the speed of the mold building process. We can reduce a typical mold build time of 6-12 weeks to just a few days. With this advancement our customers are able to get real injection molded parts to use either as production or prototype.

The cost is often less than most injection molding companies charge for a prototype mold without the life expectancy limitations. Also, our customers are saying that they often skip rapid prototyping because our process is so fast and affordable.

File Formats Accepted:

| 3D CAD formats: | IGES (*.igs, *.iges), Parasolid (*.x_t), STEP (*.step, *.stp), ProE (*.prt, *.asm), Unigraphics (*.prt) |

| 2D CAD formats: | AutoCAD (*.dwg), DXF, (*.dxf) |

| Image formats: | JPEG, TIFF, PNG, GIF, BMP |

| Other: | Microsoft Word, Excel, Powerpoint Portable Document Format (*.pdf) |

NTT Main Markets: 90% molds are exported to

Europe: UK, France, Germany, Italy, Belgium, Finland;

North America: USA, Canada, Mexico;

South America: Ecuador;

Oceania: Australia;

Africa: South Africa;

Asia: Philippines.