Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

In the realm of manufacturing, the CNC machining process, denoted by computer numerical control

machining, is a subtractive method that integrates computerized controls and machine tools.

Its fundamental principle involves the removal of layers from a solid material block.

The programming specifies the desired cuts in the metal, coordinating with the corresponding tools

and machinery to execute the machining task in an automated manner.

Product Details

The turning process primarily involves the machining of various metals.

These metals encompass a wide range of materials, including alloy steel, carbon steel, cast iron,

stainless steel, aluminum, copper, magnesium, and zinc.

Nevertheless, it is essential to note that the turning process is not limited to metals alone;

it can also be applied to plastic components and a diverse array of materials such as ceramics,

composites, thermoplastics, and thermosetting materials.

| Common Materials | |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. |

CNC Machining Tolerances

Typical machining tolerances fall within the range of ± 0.005 inches or 0.13 millimeters.

Tolerances represent the allowable variation for a specific dimension.

For instance, if a CNC machining tool has a tolerance of ± 0.01 millimeters, it means that the tool

can deviate by 0.01 millimeters in each cut.

When provided with a drawing, Our CNC machining service can achieve CNC parts with tolerances

as tight as ± 0.0002 inches.

In the absence of a drawing, all CNC parts are manufactured according to our ISO 2768 medium

standard. We can also work to even tighter tolerances, such as ± 0.025 millimeters or ± 0.001

inches, when an engineering drawing specifies critical features.

| CNC Turning Tolerances | ||

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

| *Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | ||

Applications of CNC Turning

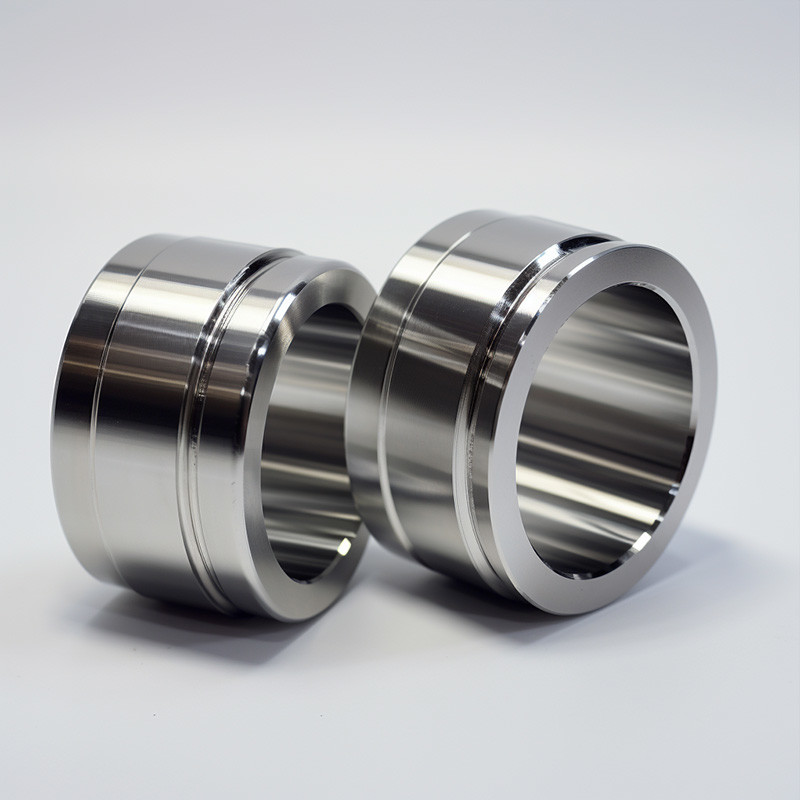

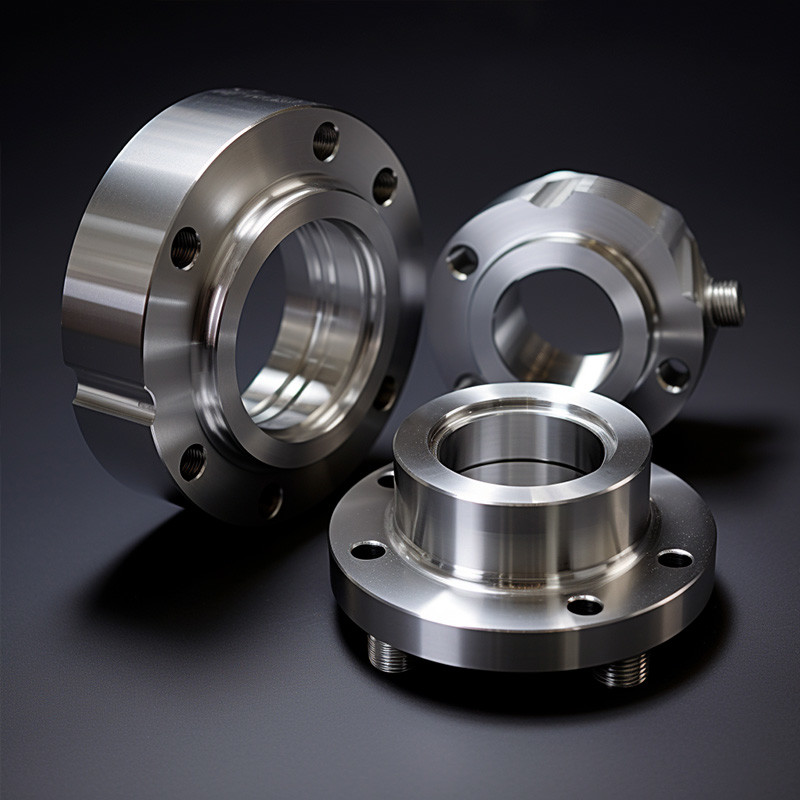

Turning, a precision manufacturing technique, is adept at producing rotational, axi-symmetric

parts featuring intricate details such as holes, grooves, threads, tapers, and contoured surfaces.

Its proficiency shines in crafting limited-quantity items, particularly custom-designed shafts and

fasteners utilized in prototypes.

Furthermore, turning serves as a valuable complementary process, enabling the addition or

refinement of features to parts manufactured through alternative methods.

Notable examples of products shaped through turning include camshafts, crankshafts, baseball bats,

bowls, cue sticks, signboards, musical instruments, and the legs of tables and chairs.

Company Profile

FAQ's

1. What is your typical lead time? Can my parts be produced on a rush basis?

When it comes to screw machine products, our standard lead time, which encompasses quoting,

manufacturing, and shipping, typically stands at one week. With a stellar on-time delivery rate

exceeding 99%, we prioritize timely fulfillment.

In certain situations, considering factors like tooling, gauges, and material availability, we might

be equipped to produce your parts on a rush basis. Don't hesitate to reach out and discuss your

specific needs!

2. Do you offer reverse engineering services or suggest cost saving measures?

Beyond offering reverse engineering services, we specialize in extracting design and engineering

insights from a variety of manufactured components. Our support extends to aiding in the design

phase, recommending optimal raw materials, and advising on efficient machining and finishing

approaches.

With the ultimate function of the part in mind, we often identify subtle design changes, material

adjustments, or tolerance optimizations that can result in cost savings without compromising the

quality or performance of your part.

3. Do you offer other services, like finishing, assembly, packaging, and logistical support?

Our range of services extends seamlessly from finishing operations to logistical support, providing

a comprehensive solution for the swift and cost-effective production of your parts. With capabilities

covering anodizing, plating, grinding, finishing, assembly, warehousing, packaging, and just-in-time

delivery, we aim to deliver a hassle-free, one-stop production process.

This approach allows you to channel your efforts into your business priorities while enjoying time

and cost savings.

4. How does you ensure the quality of my parts?

Upon confirmation of your order, a detailed Design for Manufacturing (DFM) review is carried out to

identify any potential issues affecting part quality. All incoming materials are meticulously inspected

and verified using a suite of testing equipment.

Final inspection reports are generated as part of our pre-shipment quality check. Furthermore, we

offer the option to share inspection data in real-time, enabling collaborative efforts to address any

quality concerns that may emerge during production.