Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

CNC machining, or computer numerical control machining, stands as a widely utilized manufacturing

process employing automated, high-speed cutting tools to shape designs from metal or plastic stock.

Standard CNC machines encompass 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers.

The methodology for cutting CNC parts may vary across machines—where the workpiece or the

cutting tool may move independently or in unison.

Skilled machinists proficiently operate CNC machines, programming tool paths based on the final

machined parts' geometry. CAD (computer-aided design) models furnish the necessary part

geometry information.

CNC machines exhibit the capability to precisely and repeatedly cut various metal alloys and rigid

plastics, making custom machined parts applicable across diverse industries such as aerospace,

medical, robotics, electronics, and industrial.

Product Details

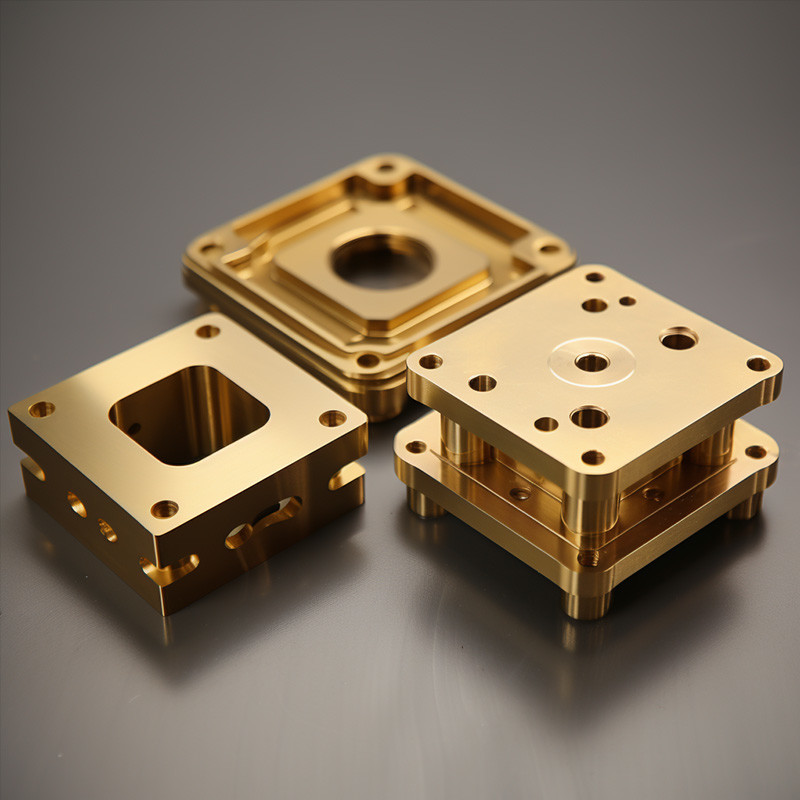

Brass Finishing and Post-Processing

| Name | Machining Marks |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

| Black oxide | Visible |

CNC Machining Using Brass Material

Brass is a metal alloy known for its low friction properties, exceptional electrical conductivity,

and distinctive golden appearance.

This material offers good machinability, making it suitable for a wide range of applications that

demand low friction and high electrical conductivity.

| Common Brass Materials | |

| No. | Properties |

| Brass Cz121 | Brass Cz121/C360 (CNC) is a highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction. |

| Brass C360 | Brass C360 (CNC) is highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction. |

CNC Machining Applications

The following industries gain the most from CNC machining:

1. Medical

2. Electronics 3. Publishing

4. Transportation 5. Woodwork

6. Construction

7. Agriculture 8.

Aerospace 9. Manufacturing

10. Automotive 11. Firearms

12. Metalwork

Company Profile

FAQ's

1. Which design file formats does We support for quoting?

To facilitate accurate and timely quoting, we only acknowledge 3D

CAD files in STL, STEP, or IGES

formats. For 2D drawings containing reference dimensions, we request submission in PDF format.

It's essential to provide comprehensive manufacturing information as part of the technical

documentation. Please note that informal communication channels such as SMS, Skype,

and email will not be considered valid for manufacturing purposes.

2. What tolerances can I achieve with CNC machining?

With CNC machining, our standard tolerances are set at 0.05 microns, catering to the needs of

most commercial and industrial applications. For special projects that demand even tighter

tolerances, feel free to consult with us. We are committed to accommodating unique requirements

and ensuring precision according to your specifications.

3. How much time does it usually take to receive a quotation?

Our standard practice involves responding to most Request for

Quotation (RFQ) submissions within

a couple of days. Should there be any deviation from this timeframe, we assure you that we will

promptly communicate any delays.

4. Can I use my own material for production?

Yes, customer-supplied material is fine so long as it fits with our

machine capabilities.