Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

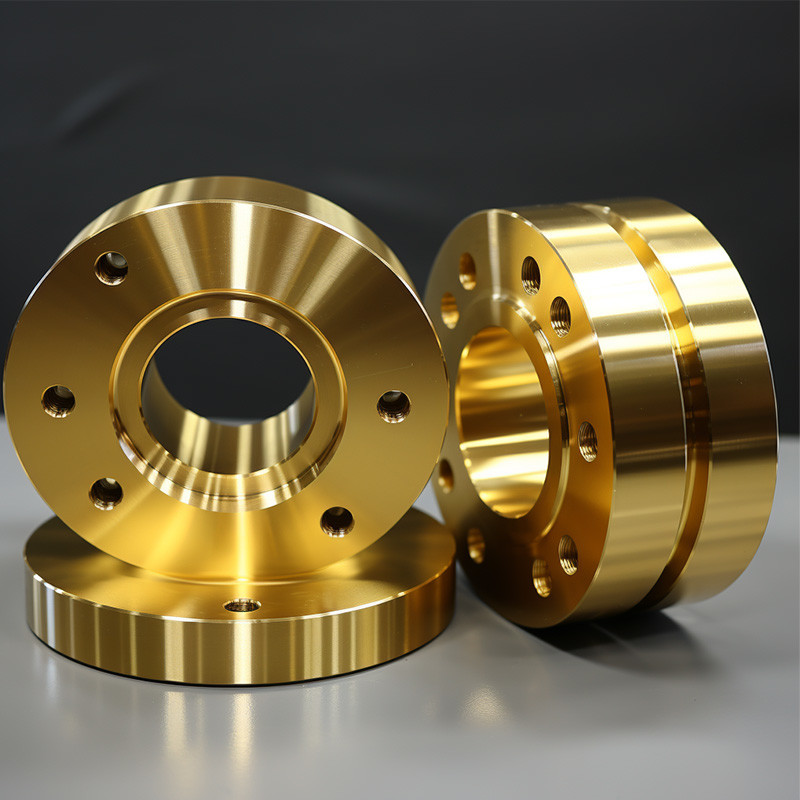

Turning Milling Brass Precision Components CNC Machining Automatic Parts

CNC Machining Mechanical Part

CNC machining, an instrumental subtractive manufacturing method, is employed for crafting

components by systematically eliminating material from a workpiece or its stock.

The machine's operations are guided by preprogrammed software and codes, dictating the

precise movement of its equipment. This versatile process encompasses various machinery

types, including turning mills, lathes, grinders, and plasma-cutting machines.

Product Details

Brass is a metal alloy known for its low friction properties, exceptional electrical conductivity,

and distinctive golden appearance.

This material offers good machinability, making it suitable for a wide range of applications

that demand low friction and high electrical conductivity.

| Common Brass Materials | |

| No. | Properties |

| Brass C3600 | It has superior machinability, thread rolling and knurling characteristics. Typically used in the manufacture of fluid connectors, threaded inserts, couplings, and more. |

| Brass C3602 | It’s strength and resistance to corrosion with properties closely resembling that of steel. It is ideal for some of the most demanding conditions such as heavy industrial parts. |

| Brass C3604 | It is used in the mass production of brass components. It is widely used in manufacturing hardware, connector, flange and other machine parts by lathe and CNC. |

| Brass C4926 | A low leaded free cutting brass which conform RoHs and Reach environment regulations. Widely used on electronic parts, precision machine, valves, and related parts. |

Brass Finishing and Post-Processing

360 Brass has a shiny yellow finish that varies depending on surface roughness.

It can be hand-polished to increase its sheen, or media blasted for more of a matte texture.

| Name | Machining Marks |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

| Black oxide | Visible |

Applications of CNC Brass Parts

Turning is a machining method that generates rotational, predominantly axi-symmetric

components, featuring diverse attributes such as holes, grooves, threads, tapers, various

diameter steps, and intricately contoured surfaces.

Products entirely crafted through turning commonly involve components produced in limited

quantities, especially for prototypes, such as tailor-made shafts and fasteners.

Moreover, turning frequently serves as a supplementary process to introduce or refine features

on parts originating from alternative manufacturing methods.

Examples of products manufactured through turning encompass camshafts, crankshafts, baseball

bats, bowls, cue sticks, signboards, musical instruments, and the legs of tables and chairs.

Company Profile

FAQ's

1. Can you ensure my designed component dimensions and tolerances are suitable

for production?

Our team of seasoned professionals is well-equipped to offer "Design for Engineering" (DFM)

support, assessing the feasibility of your designed component dimensions and tolerances for

production.

Recognizing the importance of swift responses during the ideation and testing phase,

we ensure a fast turnaround on quotes. For a comprehensive overview of the entire order

progress, you can refer to our production process page.

2. What is your typical lead time? Can my parts be produced on a rush basis?

Our typical lead time, encompassing quoting, manufacturing, and shipping, for screw machine

products is around one week. Rest assured, our on-time delivery rate exceeds 99%. Should you

require an expedited production timeframe, we can explore the possibility based on factors like

tooling, gauges, and material availability in the marketplace. Feel free to inquire!

3. Do you offer reverse engineering services or suggest cost saving measures?

Absolutely, we provide reverse engineering services and can extract design and engineering

information from a wide range of manufactured components. In addition to reverse engineering,

we offer support in designing your part, selecting optimal raw materials, and choosing effective

machining protocols and finishing steps.

With the end-use of the part in mind, we often identify minor design tweaks, material changes,

or tolerance adjustments that can result in cost savings without compromising quality or

performance.