Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

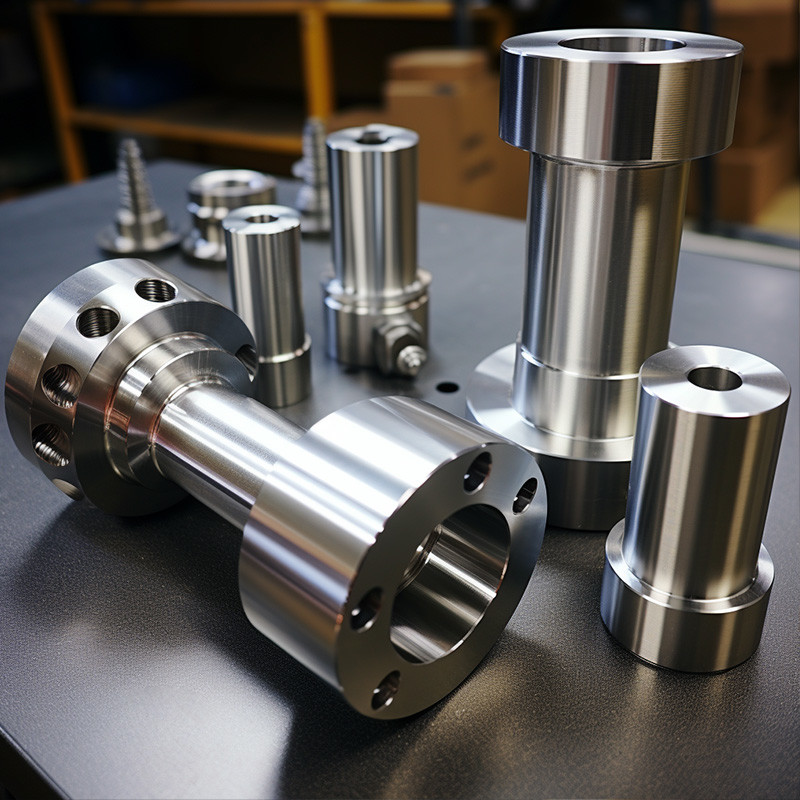

CNC turning is a subtractive manufacturing process that involves the rotation of a metal rod while

a cutting tool is applied to the material to remove excess material and shape it into final parts.

Our CNC lathes are equipped with live tooling capabilities, allowing for the machining of flat features

and holes on the workpiece. Furthermore, both outside diameter (OD) and inside diameter (ID)

threading can be performed.

Upon completion, turned parts can either retain their as-machined appearance, showcasing visible

tool marks, or undergo a bead blasting process for a smoother finish. After the production run is

finished, parts are subjected to inspection, packaged, and promptly dispatched for delivery.

Product Details

We have the capability to work with a wide variety of materials in CNC machining, such as carbon

alloys, aluminum, brass, stainless steel, high nickel alloys, and engineered plastics.

Our team is dedicated to guiding you in choosing the most suitable material for your particular

application. Even if you are contemplating materials outside our standard list,

we are well-equipped to provide assistance and expertise for the best outcomes.

| Common Materials | |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. |

| CNC Turning Tolerances | ||

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

| *Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | ||

Typical Applications of CNC Turning

Industries Maximizing the Benefits of CNC Machined Parts

The CNC milling process offers efficiency, precision, and

eliminates the reliance on manual labor,

making it applicable to various industries. Machine shops and their services play a crucial role in

the manufacturing process, catering to both prototypes and full production runs.

1. Electronics Industry:

The electronics industry heavily depends on CNC machines and CNC

milled parts for creating

electronic enclosures, circuit supports, and related components crucial for their products.

2. Commercial Industry:

CNC cutting heads play a pivotal role in producing cost-effective

commercial parts, enabling

companies to reduce production costs and enhance efficiency. Machine shop milling services are

integral to manufacturing a diverse range of mechanical parts.

3. Oil and Gas Industry:

In the petrochemical sector, CNC machines are employed to

manufacture drill bits, cylinders, pins,

rods, valves, and various other components, contributing to the operations of the oil and gas industry.

4. Medical Industry:

CNC milling tools are indispensable in the medical industry,

facilitating the production of various parts

such as implants and medical devices. CNC milling is extensively used in crafting surgical equipment,

including ventilator parts, insulin pumps, medical rods and implants, bone plates, and medical screws.

5. Aerospace Industry:

The aerospace industry has a consistent demand for CNC machined

parts, which can create complex

and customized components integral to aerospace equipment. Commonly produced parts include

electronic enclosures, landing gear, hydraulic manifolds, housings, fuel bodies, and bearing houses.

CNC machining plays a vital role in meeting the precision requirements of the aerospace sector.

Company Profile

FAQ's

1. Would you be able to create design drawings for me?

While we don't offer a standalone product design service, we do

provide Design for Manufacturing

reviews for all approved orders.

This entails collaborating with our clients to enhance the manufacturability of their 2D and 3D

drawings, address design conflicts, and reduce production costs. Learn more about preparing

your CAD drawings for manufacturing.

2. What kinds of design files does We accept for quoting?

To ensure precision and promptness in our quoting process, we

exclusively accept 3D CAD files in

STL, STEP, or IGES formats. For 2D drawings with reference dimensions, please provide them in PDF

format.

Complete manufacturing information is crucial and should be included as part of the technical

documentation. Informal communication through SMS, Skype, email, etc., will not be deemed

acceptable for manufacturing purposes.

3. What is the typical turnaround time for a quotation?

In the majority of instances, we aim to provide a response within a

few days of receiving a Request

for Quotation (RFQ). Should there be any delay in the quoting process, we commit to notifying you

at the earliest convenience.

4. How can I be assured that my design will be treated confidentially?

We take confidentiality seriously and are willing to sign and

uphold any non-disclosure or

confidentiality agreement. Additionally, our factory strictly prohibits the taking of photographs of

a customer's product without explicit permission.

Ultimately, our commitment to preserving your design's confidentiality is reinforced by our

longstanding reputation, having worked with hundreds of thousands of unique designs over many

years, without ever divulging proprietary information to third parties.