Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

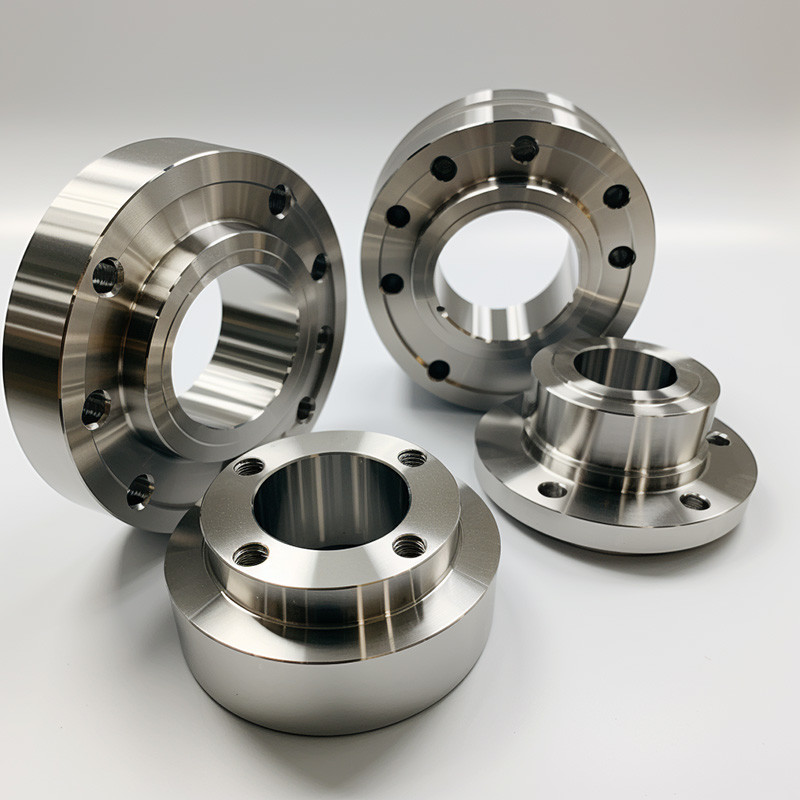

With our CNC turning process, we can swiftly produce custom prototypes and end-use production

parts, often within a single day. Utilizing a CNC lathe equipped with live tooling, we can efficiently

machine features such as axial and radial holes, flats, grooves, and slots to meet your specific

requirements.

CNC turning is often used for:

1. functional prototypes and end-use parts

2. parts with cylindrical features

3. parts with axial and radial holes, flats, grooves, and slots

Product Details

CNC machining machines possess the versatility to cut through an extensive array of materials,

encompassing aluminum, bronze, copper, ceramics, plywood, diverse steel types, stone, wood,

zinc, and various engineering materials.

This broad range of capabilities positions CNC machining as an optimal solution for prototype

creation in product development. It facilitates the ability to make accurate and swift adjustments

until achieving satisfaction with the final product.

| Common Materials | |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. |

| CNC Turning Tolerances | ||

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

| *Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | ||

Typical Applications of CNC Turning

We’ve manufactured millions of parts for all sorts of applications, but we’re especially

knowledgeable in these areas.

1. Aerospace & aviation

2. Automotive

3. Industrial machinery

4. Consumer electronics

5. Robotics & automation

6. Medical

Company Profile

FAQ's

1. Why choose CNC machining?

CNC machining stands out for its numerous benefits, making it a preferred choice in manufacturing:

1. Speed: CNC machining provides a fast production process,

allowing for the efficient creation of

end-use parts.

2. Accuracy: The precision and accuracy of CNC machining ensure

high-quality, reliable parts that

meet stringent specifications.

3. Versatility: CNC machining is highly versatile, capable of

handling a diverse range of materials and

intricate part designs with ease.

4. Cost-Effective: One of the key advantages is its

cost-efficiency. CNC machining eliminates the need

for costly hard tooling and elaborate setups, making it a cost-effective solution for various

production volumes.

2. What tolerances can I achieve with CNC machining?

Our standard tolerances for CNC machining are set at 0.05 microns, providing precision suitable for

the majority of commercial and industrial applications. If your project requires even closer tolerances,

we welcome consultation to address specific requirements and ensure optimal results.

3. How long does delivery time and quotation take?

The delivery time for parts is categorized based on complexity:

Low-complexity parts: 2-3 days

Moderate-complexity parts: 2-5 days

High-complexity parts: 5-15 days

Quoting time is dependent on the design complexity:

Simple designs: 1 business day or faster

Moderate to complex designs: 3+ business days

For an assessment and quote on your design, please contact our

team.

4. Quality Assurance Commitment

We prioritize customer trust by implementing established quality management principles to elevate

customer satisfaction and consistently enhance our performance and capabilities.

Drawing on decades of experience, we adhere to stringent regulations and maintain PPAP compliance

for the automotive, aerospace, and medical device industries.

These industries serve as benchmarks for all the products we manufacture.