Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

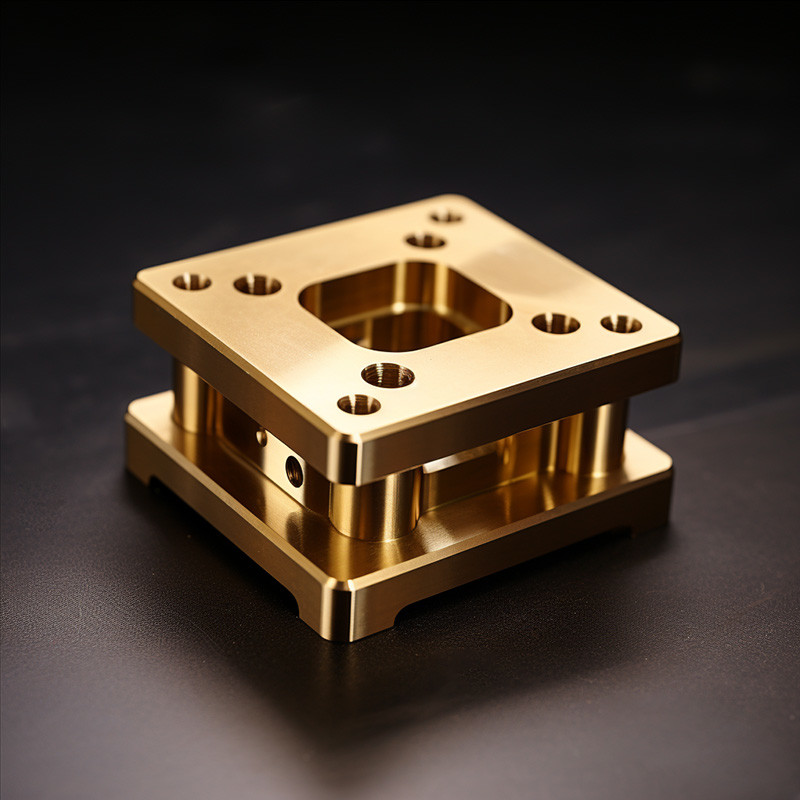

Custom CNC Machining Brass Part Precision CNC Part Milling CNC Brass Parts

CNC machining is a subtractive manufacturing method that automates the removal of material

from raw stock using computer-generated instructions.

Typically, CNC machines fall into two categories: those that keep the raw stock stationary while

the cutting tool rotates and those that rotate the raw stock while moving it against a stationary

tool.

Various adaptations and combinations of these techniques exist to create parts with intricate

features.

Product Details

Brass Finishing and Post-Processing

| Name | Machining Marks |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

| Black oxide | Visible |

CNC Machining Using Brass Material

Brass is considered one of the most machinable materials, particularly when compared to

aluminum.

While aluminum can often cause tools to stick, brass tends to have less adhesion to machining

tools during the process.

This metal alloy, comprised of copper and zinc, is extensively used worldwide, yet its full

potential in machining remains underutilized in the United States.

| Common Brass Materials | |

| No. | Properties |

| Brass Cz121 | Brass Cz121/C360 (CNC) is a highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction. |

| Brass C360 | Brass C360 (CNC) is highly machinable alloy with good tensile strength and natural corrosion resistance. Ideal for parts that require low friction. |

CNC Brass Parts Applications

Parts produced by this type of machining are commonly found in the automotive, aerospace,

medical, marine, and hydraulic industries. Such as headers, housings, shafts, shells, knobs, rotors,

terminals, fittings, pistons, valve stems, and similar products.

Company Profile

FAQ's

1. What's the general surface texture of CNC milled and turned parts?

Typically, as-machined milled parts exhibit a surface roughness of approximately 3.2μm

(with the potential to reach 1.6μm for newer machines).

In contrast, for turned parts, achieving a surface roughness as low as 0.8μm is possible,

ensuring that machining speed adjustments are not always necessary.

2. What tolerances can I achieve with CNC machining?

Our standard tolerances for CNC machining are 0.05 microns, suitable for most commercial and

industrial applications.

For projects with more stringent tolerance requirements, please consult with us to discuss your

specific needs.

3. What is the typical delivery time and quotation process?

Delivery time is determined based on the complexity of the parts.

For low-complexity parts, the lead time is typically 2-3 days.

As the complexity of the parts increases, the lead time can range from 2-5 days.

High-complexity parts may require a lead time of 5-15 days.

Similarly, the quotation process varies depending on the complexity

of your design.

Quotes can be provided in as little as 1 business day, or it may take 3 or more business

days for more intricate designs.

If you have a design that you would like our team to assess and

provide a quote for,

please don't hesitate to contact us.

4. What industries do you typically work in? Who are your typical customers?

Our extensive experience spans a wide array of industries, making it challenging to pinpoint

those we haven't served.

Our clientele consists of heavy equipment manufacturers, general commercial enterprises,

and businesses within the industrial, transportation, medical, and consumer sectors, among

many others.

While our customer base extends across the United States, Europe, and globally, they share

a common requirement: top-notch machined parts that adhere to specifications,

meet deadlines, and remain budget-friendly.