Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

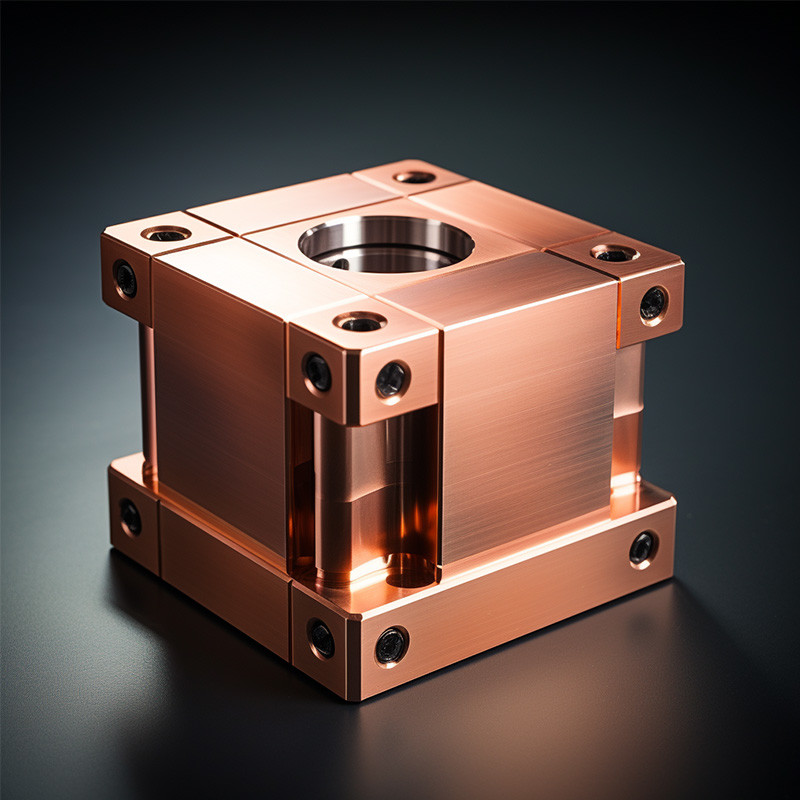

Custom OEM Service CNC Copper Parts CNC Milling Part CNC Precision Machining Parts

CNC Machining, short for Computer Numerical Control machining, is a widely adopted

manufacturing process utilizing automated, high-speed cutting tools to shape metal or plastic

stock into desired designs.

The standard CNC machine types encompass 3-axis, 4-axis, and 5-axis milling machines, lathes,

and routers.

The method of cutting CNC parts can vary, with options such as keeping the workpiece stationary

while the tool moves, holding the tool in place while the workpiece rotates and moves, or

simultaneous movement of both the cutting tool and workpiece.

Experienced machinists operate CNC machines by creating tool paths based on the final part's

geometry, which is derived from a CAD (Computer-Aided Design) model.

CNC machines exhibit exceptional precision and repeatability, capable of cutting nearly any metal

alloy and rigid plastic.

This versatility makes custom machined parts suitable for various industries, including aerospace,

medical, robotics, electronics, and industrial applications.

Product Details

Copper Machining Services

Our comprehensive copper CNC machining service allows us to manufacture intricate copper parts

in C110 and C101.

Copper parts are known for their corrosion resistance and versatility, making them suitable for

applications that demand electrical conductivity and high-quality aesthetics.

Our CNC machining capabilities cover a wide range of mill and turning centers, enabling us to craft

various components – from straightforward "as-machined" workpieces to intricate, organic geometries

with precise tolerances.

When you choose us for your copper parts, you can take advantage of up to 7 different post-processing

and surface finishing options, including bead blasting, powder coating,

smooth machining, and polishing.

| Name | Machining Marks |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

How much does CNC machining copper cost?

The cost of CNC machining copper varies based on several factors, including the part's complexity,

size, and the type of copper used.

These variables impact the machine requirements, production time, and raw material expenses,

ultimately influencing the overall cost.

| Common Copper Materials | |

| No. | Properties |

| Copper C110 | Copper (C110) is a pure at 99.90% copper alloy, with universal for electrical applications high thermal conductivity and good corrosion resistance. |

| Copper C101 | Copper (C101), 99.99% pure, is a copper alloy with excellent conductivity and high corrosion resistance and toughness. |

CNC Machining Applications

Copper is a popular choice for many products and components:

1. Sensor Parts 2.

Auto Parts 3.

Respirator Parts

4. Power Tools

5. Hydraulic Parts 6. Aircraft

Parts

7. Dental Handpieces 8. Drone Parts

9. Motor Parts

10 .Bicycle Parts 11.

Robotic Parts 12. Appliance Parts

Company Profile

FAQ's

1. How much does CNC machining copper cost?

The cost of CNC machining copper varies based on several factors, including the part's complexity,

size, and the type of copper used.

These variables impact the machine requirements, production time, and raw material expenses,

ultimately influencing the overall cost.

2. Copper Machining Services

Our comprehensive copper CNC machining service allows us to manufacture intricate copper parts

in C110 and C101.

Copper parts are known for their corrosion resistance and versatility, making them suitable for

applications that demand electrical conductivity and high-quality aesthetics.

Our CNC machining capabilities cover a wide range of mill and turning centers, enabling us to

craft various components – from straightforward "as-machined" workpieces to intricate, organic

geometries with precise tolerances.

When you choose us for your copper parts, you can take advantage of up to 7 different

post-processing and surface finishing options, including bead blasting, powder coating, smooth

machining, and polishing.

3. Lead Time for Your Parts

We can produce high-quality parts in as little as two weeks if you furnish us with comprehensive

2D and 3D CAD models.

However, for more intricate parts with additional requirements or special features, the lead time

may be longer. Feel free to request a quote to obtain precise lead times tailored to your project.

In terms of shipping, the majority of our shipments are dispatched via air freight. The transit time

from China to Europe or North America typically takes a few days.

4. Ensuring Part Quality

Our commitment to ensuring the quality of your parts includes a comprehensive approach:

1. Design for Manufacturing (DFM) Review: After your order is confirmed, we conduct a thorough

DFM review to identify and address any potential issues that could impact part quality.

2. Incoming Material Inspection: All incoming materials undergo rigorous inspection and

verification using advanced testing equipment to ensure they meet our quality standards.

3. Final Inspection Reports: Before shipment, each part undergoes a final inspection.

We provide detailed inspection reports, giving you complete visibility into the quality of your parts.

4. Real-time Inspection Data: We have the capability to share inspection data with you in real-time.

This collaborative approach allows us to address any quality concerns during the production process,

ensuring that your specifications and expectations are met.

Our commitment to quality control is integral to delivering parts that meet your exacting standards.