Senlan Precision Parts Co.,Ltd. |

|

Verified Suppliers

|

|

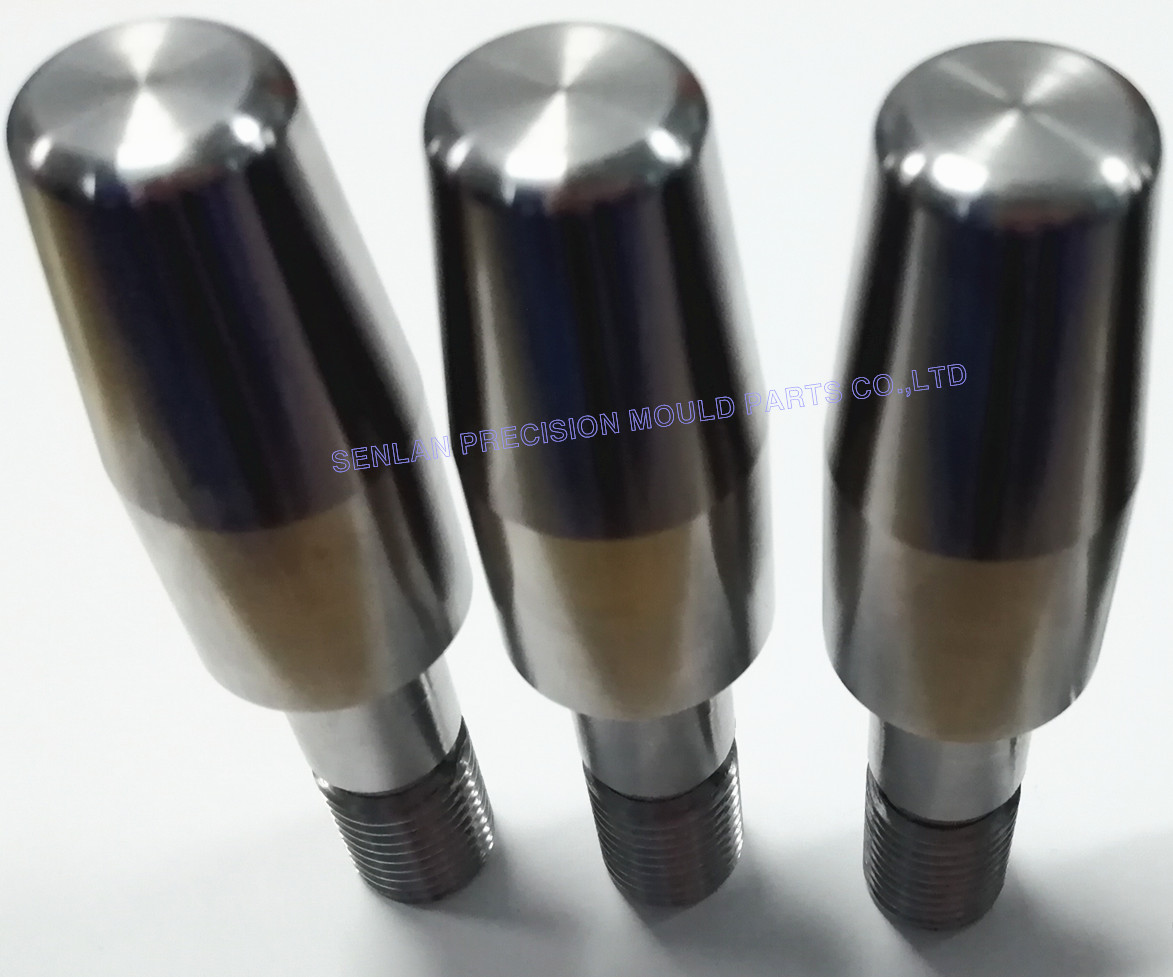

Polished High Precision Cnc Machined Parts / Thread Cnc Turning

Parts

CNC turning is a part of machining. There are two main types

of cnc turning machining: one is to fix the turning tool, to

process the unformed workpiece in the rotation, and the other is to

fix the workpiece through the high-speed rotation of the workpiece.

The lateral and longitudinal movement of the tool holder) is

precision machined.

On the lathe, drills, reamer, reamer, taps, dies and knurling tools can also be used for machining. Lathes are mainly used for machining shafts, discs, sleeves and other workpieces with a rotating surface. They are the most widely used type of machine tool in machinery manufacturing and repairing plants.

Product Detail

| Product name | Polished High Precision Cnc Machined Parts / Thread Cnc Turning Parts |

| Tolerance | Size tolerance within +/-0.002mm |

| Material | SKD61, SKH51, SKD11, SK2, YK30, 55#Steel etc. |

| Grinding Precision | 0.002mm |

| Surface roughness | RA0.6 |

| Verticality | 0.005mm |

| Tolenrance | 0.005mm |

| Specification and Variables | 1)Highly polished finish 6-8 micro finish. |

| Sizes | Special sizes can be customized |

| Quality | Guarantee high quality |

Process

1. It is easy to ensure the precision of each working surface of

the workpiece; when machining, the workpiece rotates around a fixed

axis, and each surface has the same rotation axis, so it is easy to

ensure the coaxiality between the processing surfaces.

2. The cutting process is relatively stable; in addition to

the discontinuous surface, the lathe machining process is generally

carried out continuously, unlike milling and planing, in the

process of one pass, the cutter has multiple cuts and cuts,

resulting in Impact.

3. Suitable for the finishing of non-ferrous metal parts; some

non-ferrous metal parts, because of the low hardness of the

material itself, plasticity is better, it is difficult to obtain a

smooth surface with other processing methods.

4. The tool is simple; the turning tool is the simplest one of

the tools, manufacturing, sharpening and installation are very

convenient, which is convenient to select a reasonable angle

according to the specific processing requirements.

Machinery & Equipments

Why choose us

Advantages

(1) Competitive in Price

As a manufacturer, we are looking for long-term business partners.

Therefore we can provide very competitive market price.

(2) Quality in Material

We have stable raw marterial supporting us, to provide variable

types and qualified materials into production.

Such as SKD-11,SKH-51,Tungten carbide,ASP-23,ASP-60etc., are our

regular materials in stock.

(3) Precision in Size

How precision we can do in size is can meet MISUMI standard.

(4) Fast in Delivery

Because of well-organized management in Surpass, usually it only

takes 15 days to delivery finished goods to customer.

Delivery & Payment & After-sale Service

| Delivery & Payment & After-sale Service | |

| Delivery | 1.Express by air (UPS,DHL,FedEx,TNT,EMS etc.) |

| Payment | 1.T/T payment,L/C,D/A,D/P, |

| After-sale Service | Nice after-sale service will be offered and it is a good tradition in our factory. |